Water purification and water production device

A water production device and water purification technology, which is applied in the field of water purification system and portable reverse osmosis water purification system, can solve the problems of not easy to carry, complicated manufacturing process, high cost of water purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

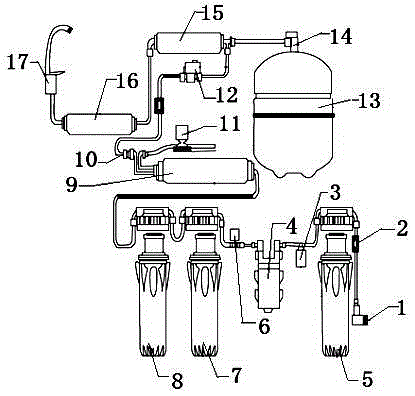

[0013] Such as figure 1 The shown water purification device includes self-priming motor 1, low pressure switch 2, PP cotton filter element 5, TDS sensor 3, booster pump 4, water inlet solenoid valve 6, granular activated carbon container 7, compressed activated carbon Container 8, reverse osmosis device 9, check valve 10, waste water solenoid valve 11, high pressure switch 12, pressure tank 13, pressure tank ball valve 14, rear activated carbon device 15, rear antibacterial film 16 and pure water faucet 17; The self-priming motor 1 is connected to the PP cotton filter core 5 through the low pressure switch 2; the PP cotton filter core 5 is connected with the booster pump 4 through the TDS sensor 3; The container 9 and the water inlet solenoid valve 6 are connected to the booster pump 4; the check valve 10 and the waste water solenoid valve 11 are connected to the reverse osmosis device 9; the check valve 10 is connected to the rear activated carbon through a high pressure swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com