Automatic bottle rotating bottle

An automatic, bottle-turning technology, applied in the directions of shaking/oscillating/vibrating mixers, mixers, dissolving, etc., to achieve the effects of sufficient shaking, high shaking efficiency and uniform shaking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

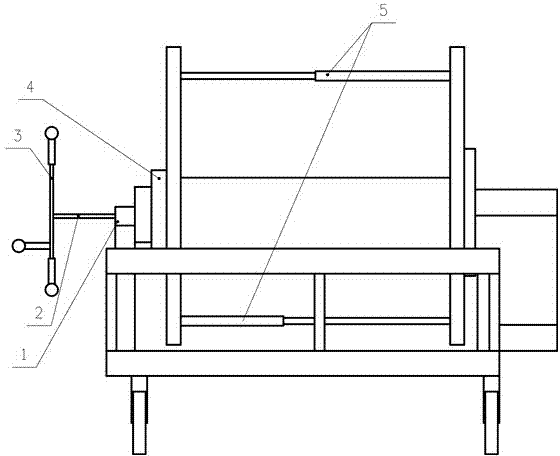

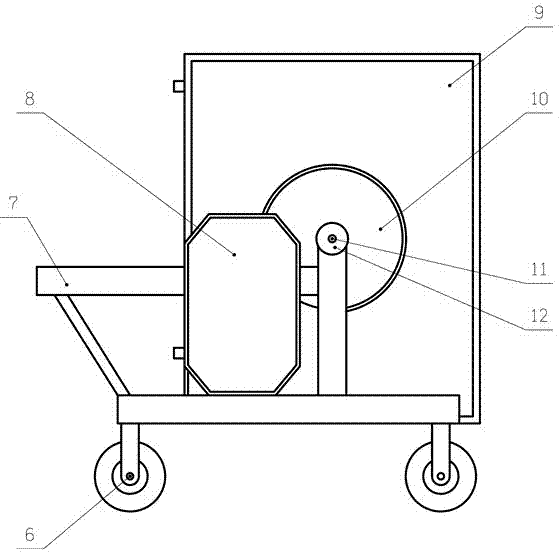

[0013] Such as figure 1 with figure 2 As shown, an automatic bottle turning machine consists of a sterilizing car chuck (9), a main frame (7), a control box (8), a chuck gear (10), a gland bolt (11), a chuck spindle ( 12), universal wheel (6), chuck bearing seat (1), rotating screw (2), handle (3), fixed nut sleeve (4) and telescopic connecting pipe (5). The sterilizing vehicle chucks (9) are respectively installed on both sides of the main frame (7), and the movement of the two sterilizing vehicle chucks (9) on the main frame (7) is controlled by rotating the screw rod (2). The telescopic connecting pipe (5) adjusts the distance between the chucks of the two sterilizing vehicles. The control box (8) is installed on the left side of the main frame. The control box is equipped with a motor, a frequency converter and a reducer, and the reducer controls the gears of the chucks. (10), the chuck gear (10) is embedded in the chuck main shaft (12), and the chuck main shaft (12) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com