Reflection rotary spray head

A rotary, sprinkler technology, applied in the direction of injection devices, sprinkler devices with movable outlets, etc., can solve the problems of uneven rotation, accelerated wear of bearings, vibration of upper water pipes, etc., to achieve reliable speed regulation methods and prolong service life. , the effect of less failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

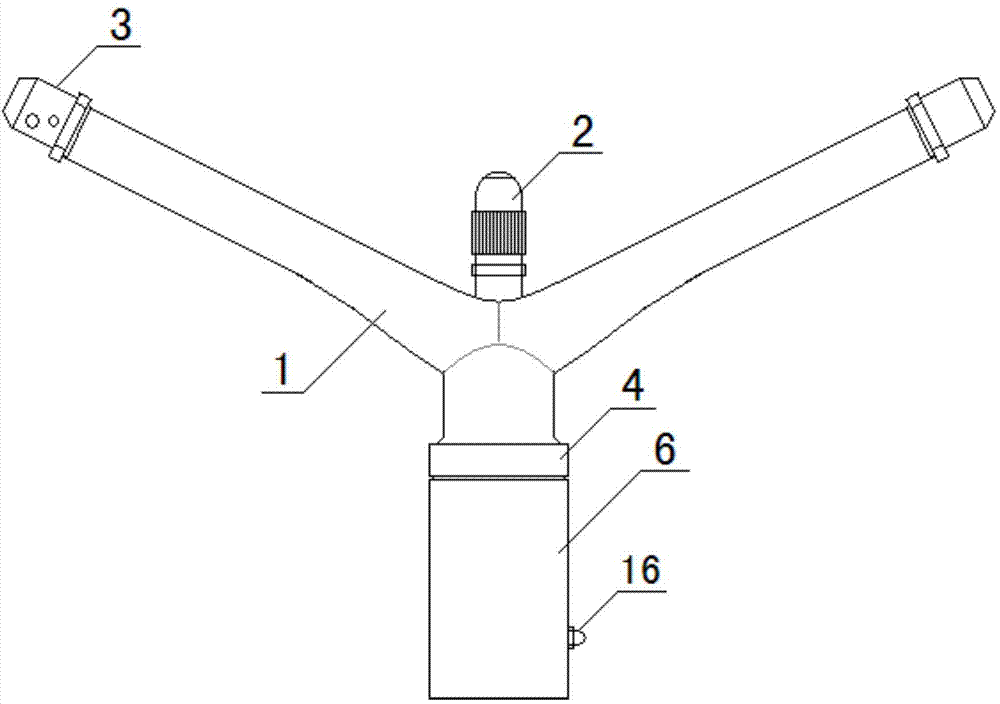

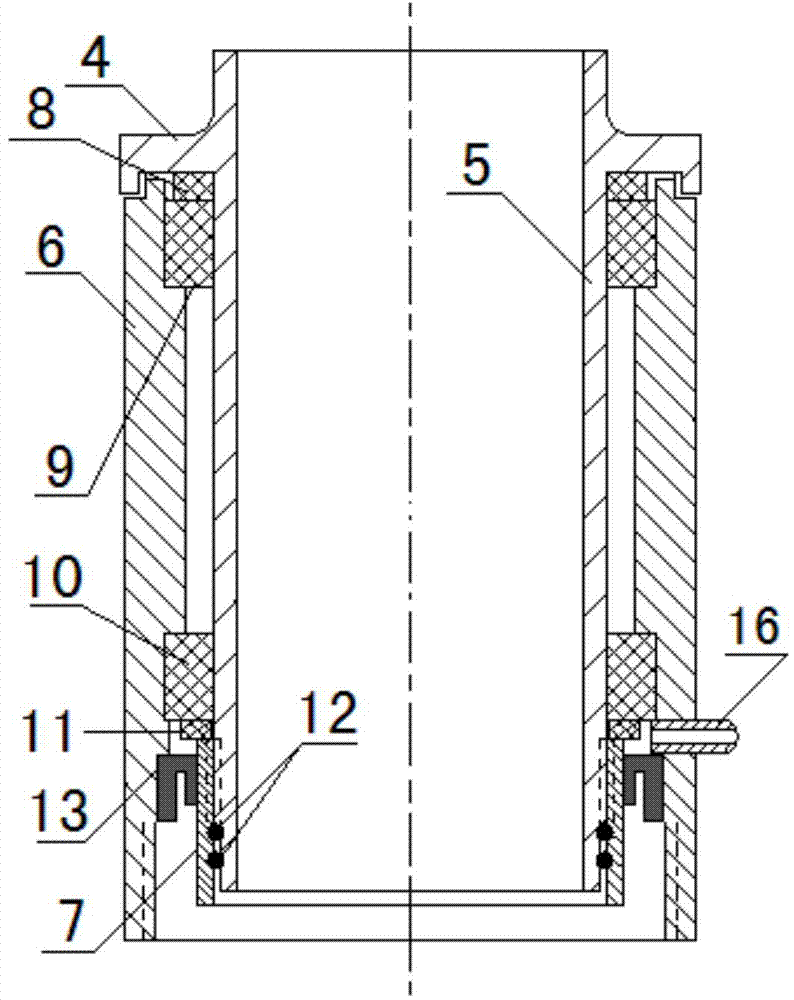

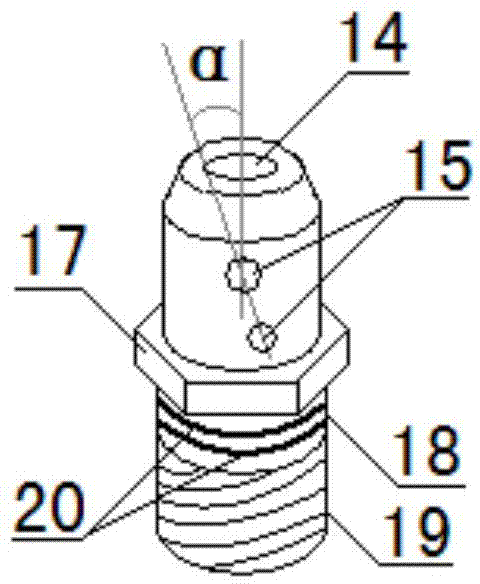

[0016] By the attachment figure 1 , 2 Shown: The spray head includes a V-shaped rotating arm 1, a round-head sprinkler nozzle set on the V-shaped rotating arm 1, a nozzle 3 arranged on the top of the V-shaped rotating arm 1, and a dustproof connection under the V-shaped rotating arm 1. The cap 4, the water inlet shaft tube 5 arranged under the dust cap 4, the oil lubrication base 6 sleeved outside the water inlet shaft tube 5, and the sealing screw plug 7 connected under the water inlet shaft tube 5, the water inlet A first nylon washer 8, a first nylon bearing 9, a second nylon bearing 10, and a second nylon washer 11 are arranged from top to bottom between the shaft tube 5 and the oil lubrication base 6. The bottom of the water inlet shaft tube 5 With sealing plug 7 ( Figure 5 As shown, the sealing screw plug 7 has the dual function of sealing and adjusting the axial gap) two sealing rings 12 are arranged between the sealing screw plug 7 and the oil lubrication base 6 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com