Horizontal permeable reaction layer for soil remediation and soil remediating method

A technology of soil remediation and infiltration reaction wall, which is applied in the field of environmental improvement engineering, and can solve the problems that chromium pollution treatment cannot be solved well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] For organic pollution sites, the permeable reaction layer can be composed of activated carbon, and when organic matter passes through, it can be adsorbed by activated carbon.

Embodiment approach

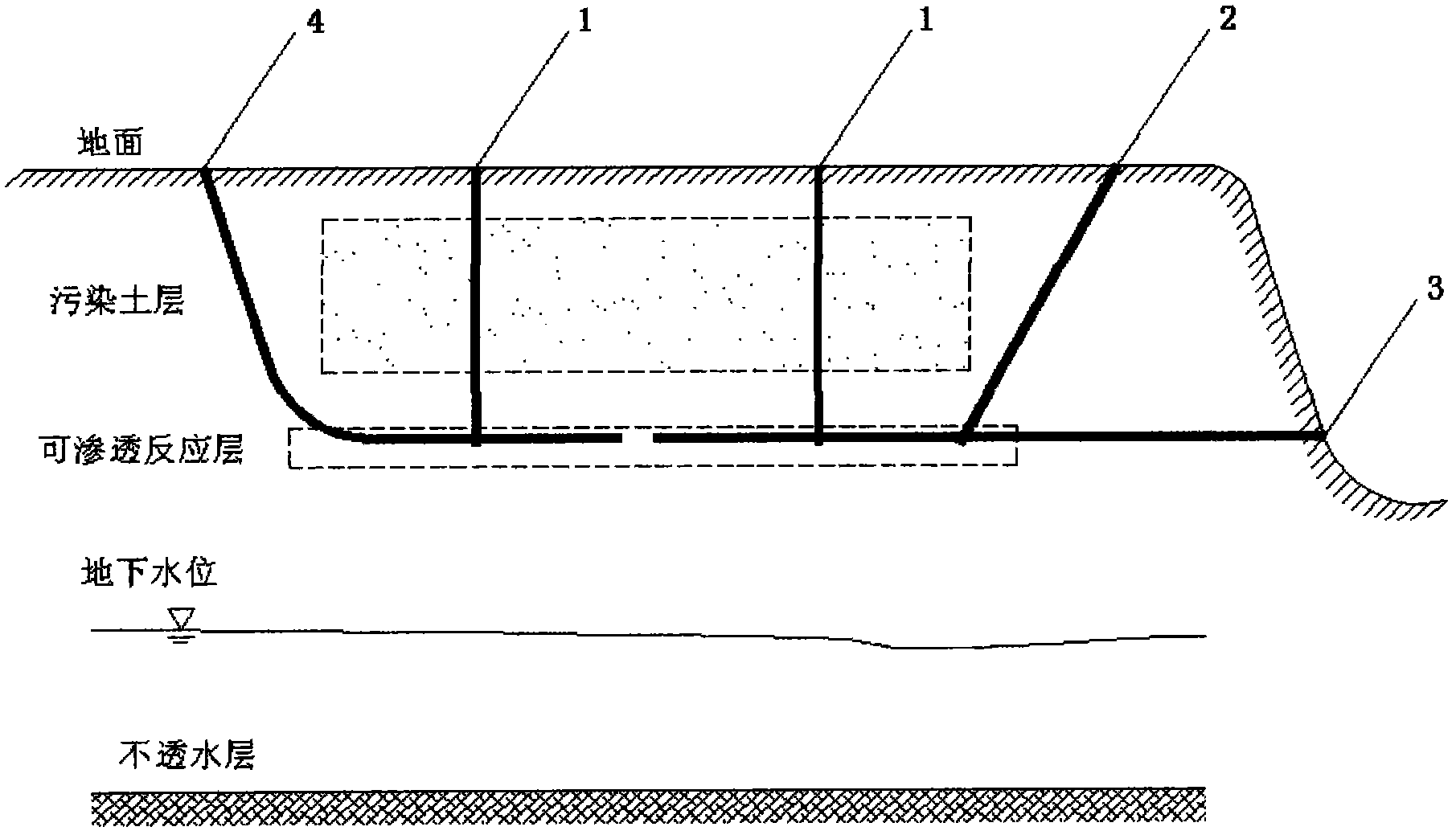

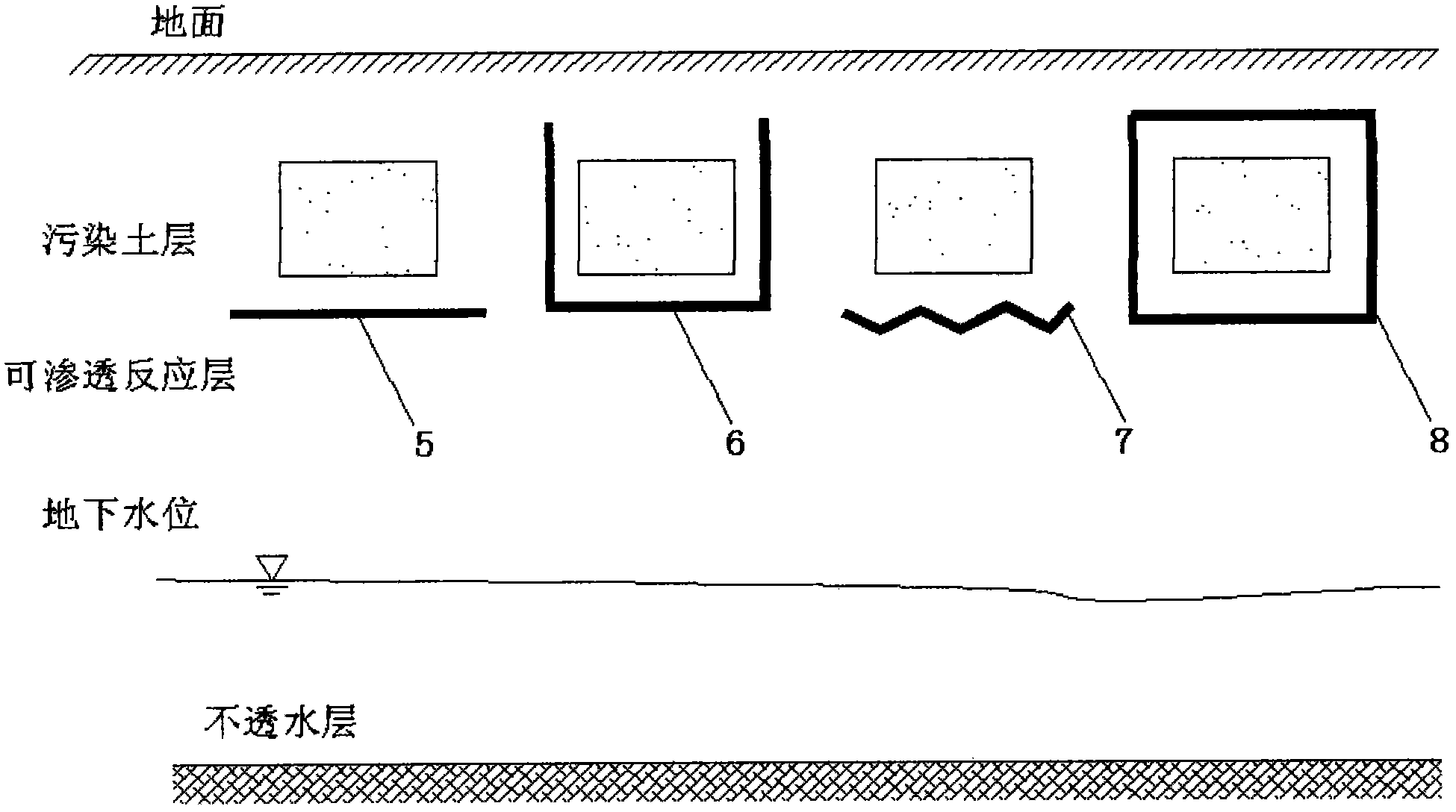

[0037] For organically polluted sites in mountainous and hilly areas with relatively complete aquifers, it is suitable to use figure 2 The one-shaped horizontal permeable reaction layer 5 in the middle part adopts the wave type 7;

[0038] For organically polluted sites with poor permeability and low groundwater table, it is suitable to use figure 1 Middle vertical perfusion hole 1;

[0039] For organically polluted sites with poor permeability, the horizontal spacing of injection holes should not be too large, and should be controlled within 1.5 to 3 meters;

[0040] For organically polluted sites with poor permeability, the concentration of the injected powdered activated carbon slurry should not be too high, and should be controlled at 1-5%;

[0041] After the perfusion hole arrangement is designed, start drilling and perfusion hole by hole. The perfusion head with a length of 0.5 meters is used for perfusion, and the perfusion volume should be sufficient to form a perme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap