Preparation device and manufacturing method of annular wire mesh cold storage filler for regenerator

A regenerator and annular technology, which is applied in the field of preparation devices for regenerator annular wire mesh cold storage packing, can solve the problems of waste of resources, difficulty in ensuring consistency, and high cost, achieve flatness and concentricity guarantee, reduce impact and Wear and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

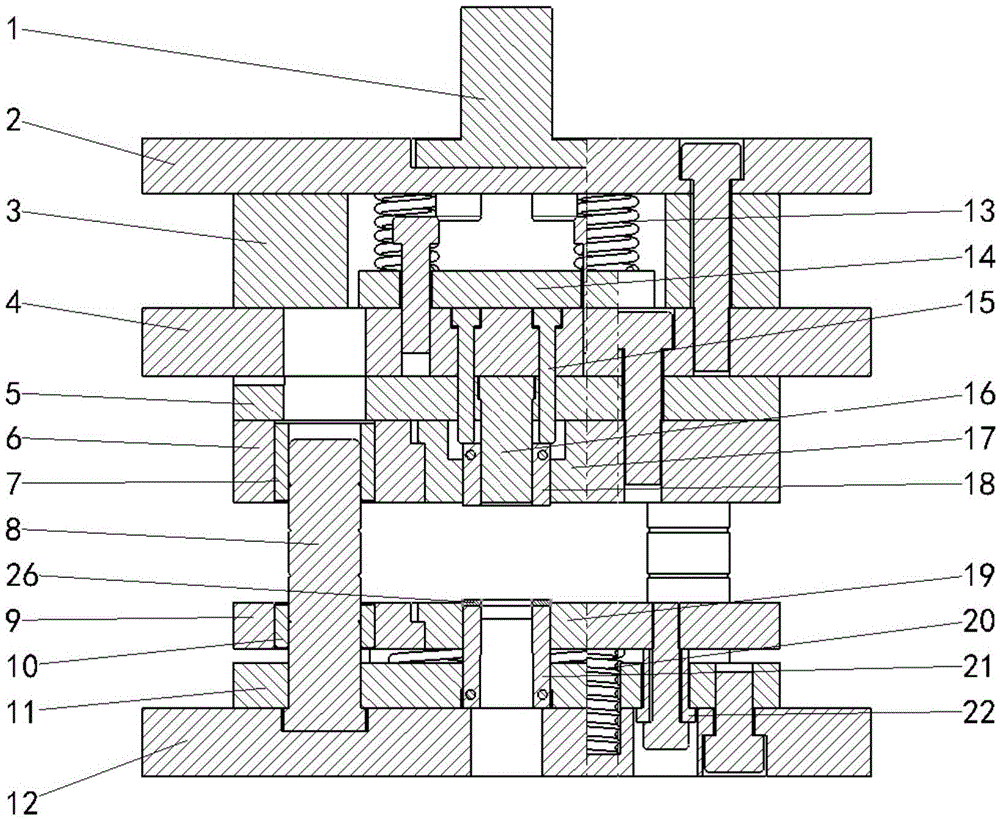

[0039] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

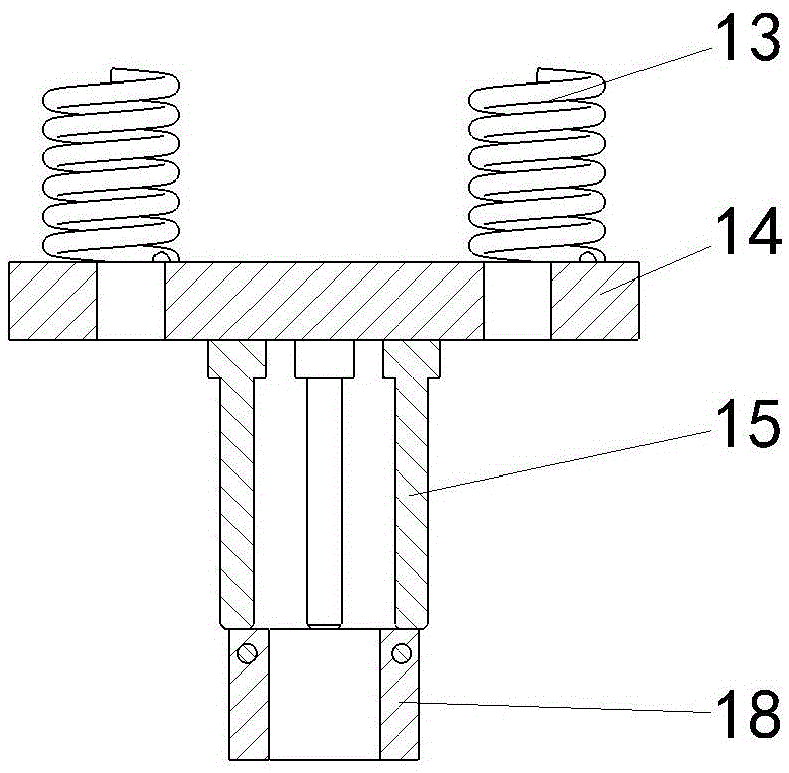

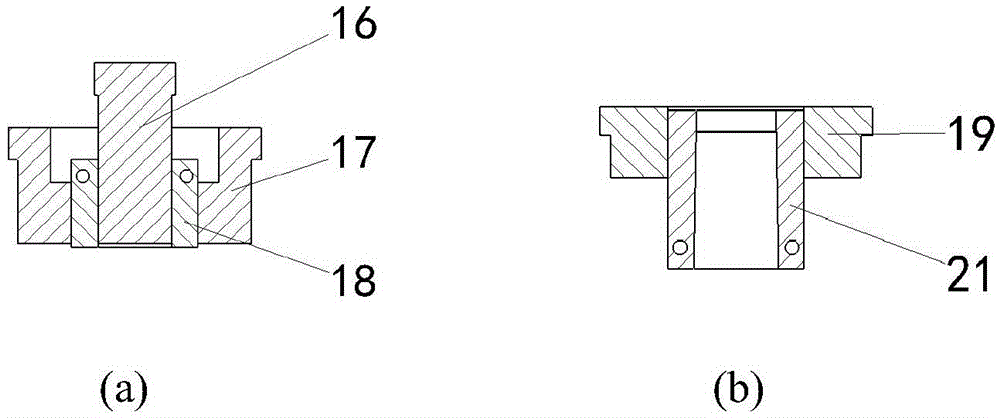

[0040] The invented preparation device for regenerator annular wire mesh cold storage packing consists of mold handle 1, upper supporting plate 2, upper cushion block 3, upper mold base 4, upper splint 5, female mold 6, upper guide sleeve 7, guide post 8 , outer stripping plate 9, lower guide sleeve 10, lower backing plate 11, lower die base 12, upper spring 13, punching plate 14, punching rod 15, punch 16, female die insert 17, inner stripping block 18 , Outer plate entry 19, lower spring 20, male mold core 21, contour sleeve 22, is characterized in that the device is a composite mold, wherein mold handle 1, upper supporting plate 2, upper pad 3, The upper mold base 4, the upper splint 5, the female mold 6, the upper guide sleeve 7, the upper spring 13, the punching plate 14, the punching rod 15, the punch 16, the core insert ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com