The side frame assembly and positioning tooling of the clothes rack automatic assembly system

An automatic assembly and positioning tooling technology, applied in the direction of assembly machines, manufacturing tools, workpiece clamping devices, etc., can solve the problems of difficult positioning and fixing of side frames, poor practicability, unreasonable design, etc., to achieve mechanical automation control, easy Positioning and fixing, the effect of improving the degree of mechanical automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

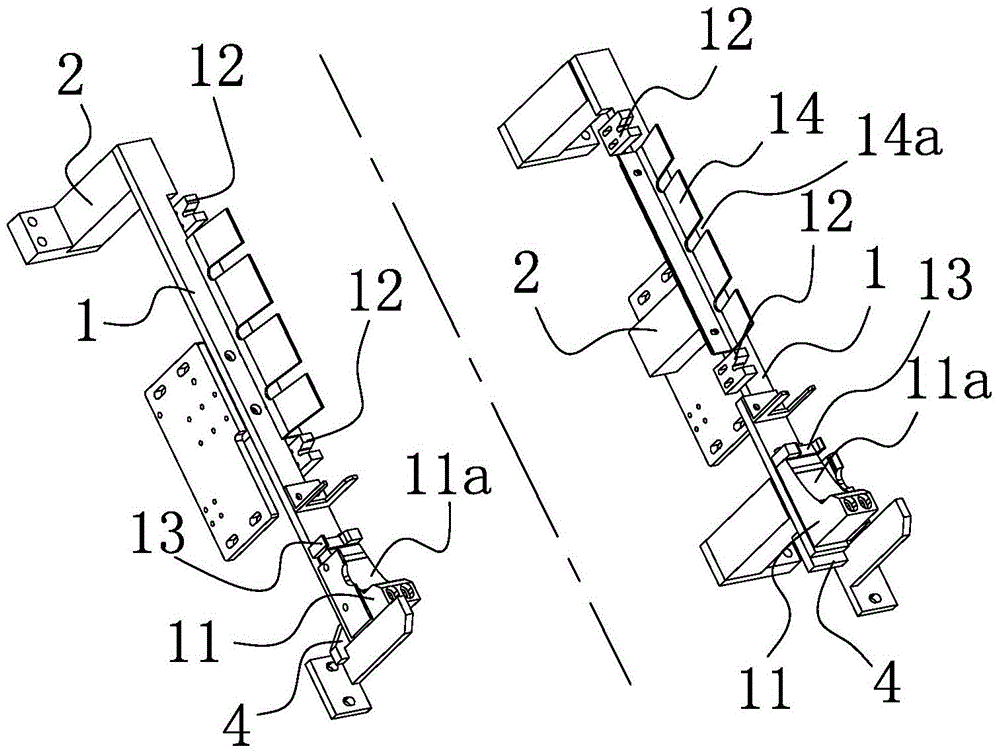

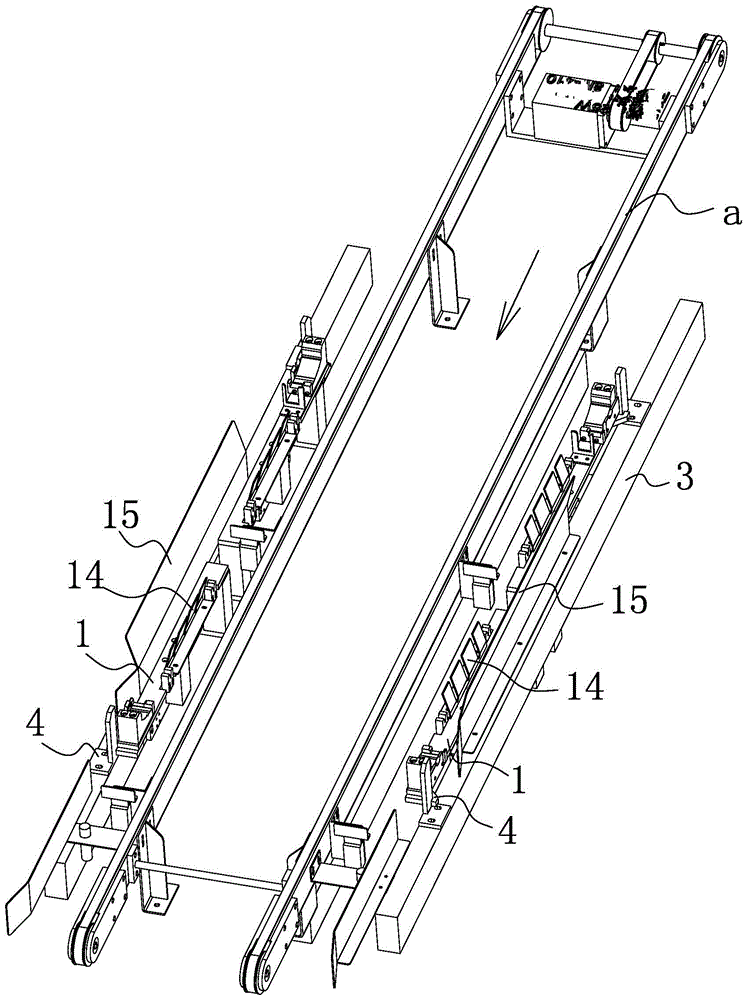

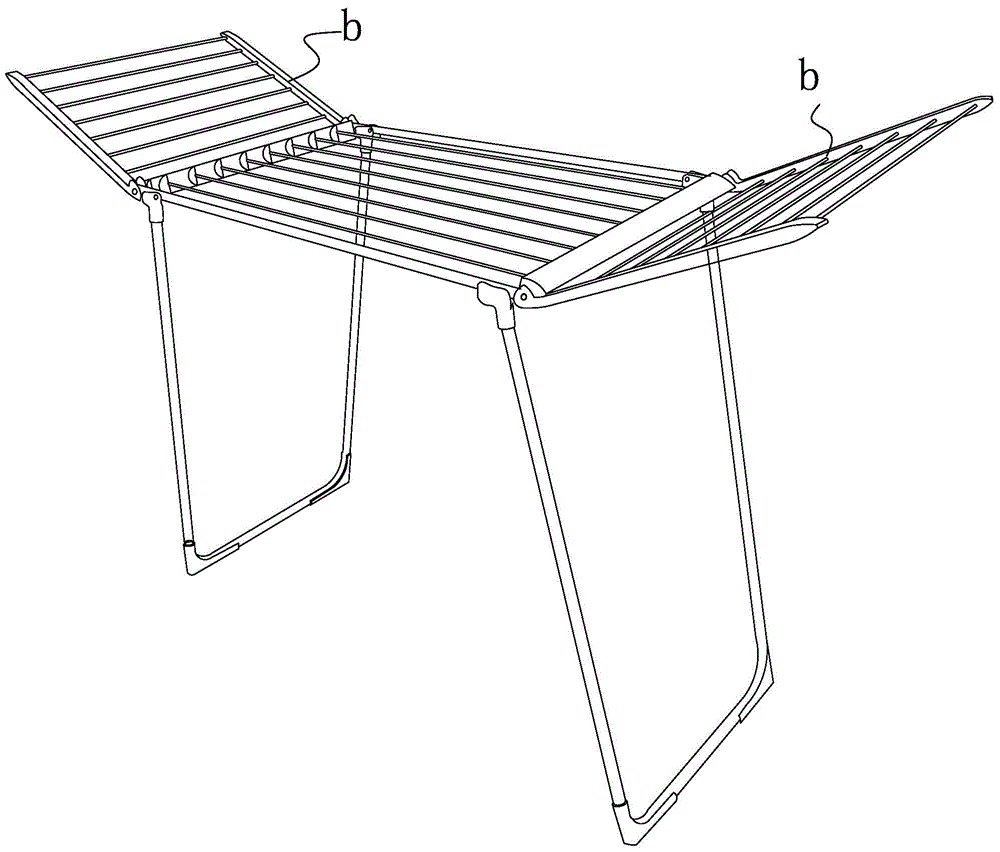

[0023] Such as Figure 1-3 As shown, the side frame assembly and positioning tooling of the clothes rack automatic assembly system includes two symmetrically arranged and strip-shaped lifting arms 1, and the lifting arms 1 are connected to a lifting drive mechanism that can drive them to rise and fall in the vertical direction. One end corresponding to each lifting arm 1 has a side frame positioning seat 11 respectively, and each side frame positioning seat 11 has an arc-shaped positioning surface 11a matching with the shape of the side frame, corresponding to each lifting arm 1 There are several V-shaped seats 12 arranged at intervals on one side, and each lifting arm 1 is also provided with a side frame that can prevent the side frame from moving between the two lifting arms when the side frame is placed on the side frame positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com