Single-arm manipulator

A manipulator and single-arm technology, applied in the direction of manipulators, program-controlled manipulators, metal processing equipment, etc., can solve problems such as unusable, low efficiency, and impact on work efficiency, so as to increase the conveying stroke, improve conveying efficiency, and save installation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

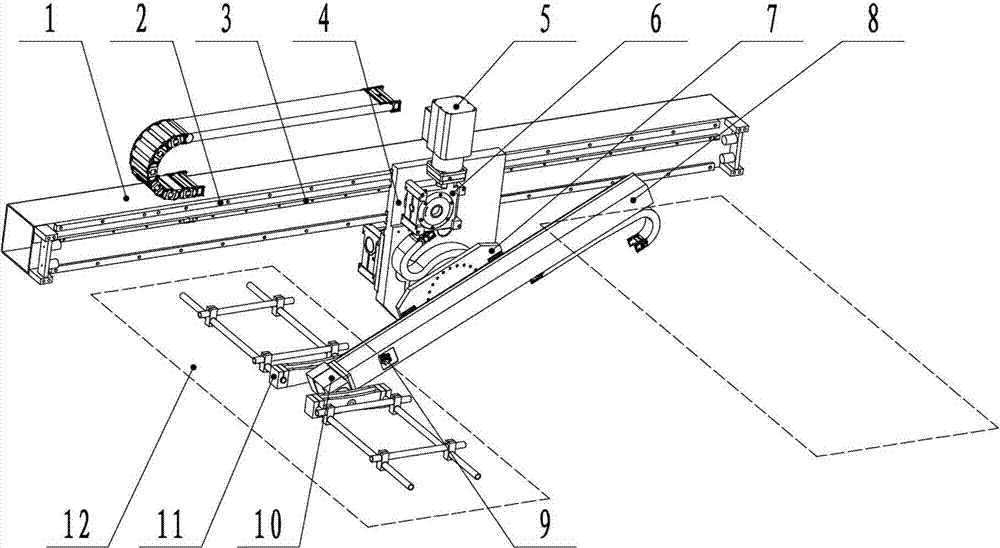

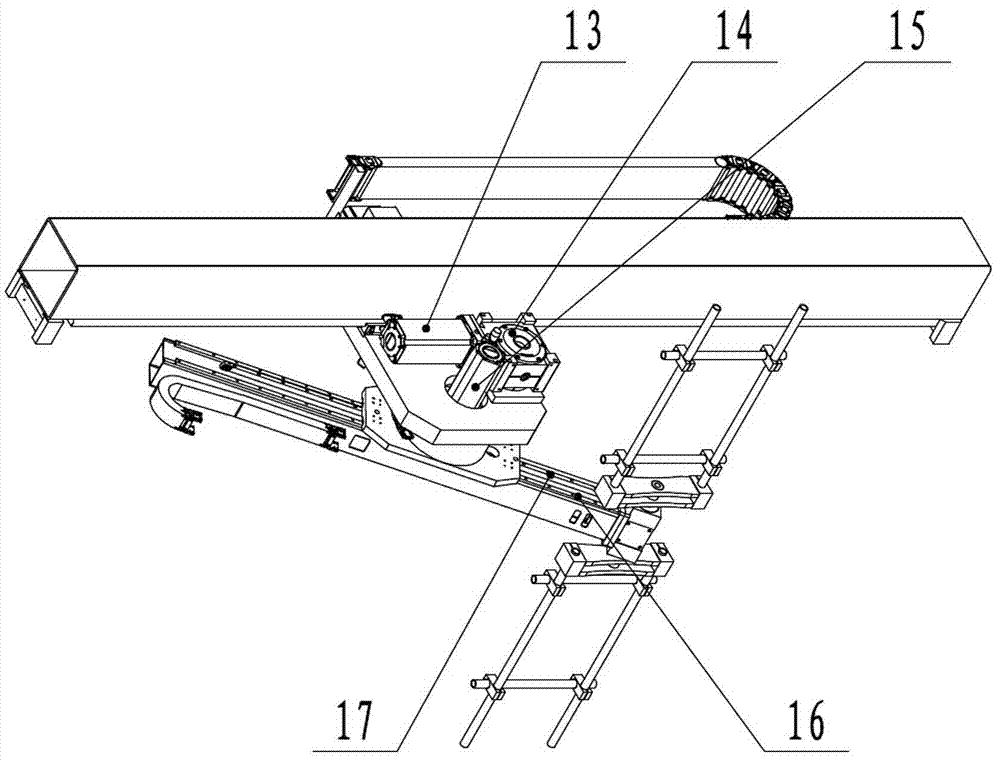

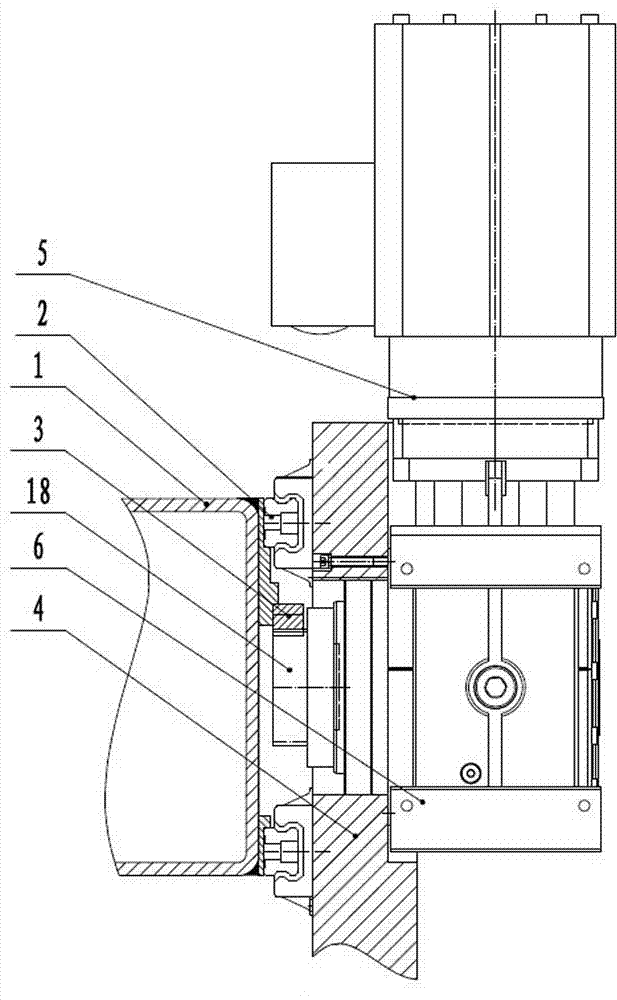

[0031] Attached below figure 1 to attach Figure 8 The present invention is further described.

[0032] This single-arm manipulator includes:

[0033] beam 1, which is horizontally arranged between two presses;

[0034] Translating the main board 4, which is slidably installed on the beam 1 through the guide rail I 2;

[0035] The rotating main board 7 is mounted on the translational main board 4 in rotation, and its rotation axis is perpendicular to the translational main board 4;

[0036] The arm 8 is slidably installed on the rotating main board 7 through the guide rail II 16;

[0037] end effector 11, which turns the end of the arm 8, and whose axis of rotation is perpendicular to the arm 8;

[0038] It also includes a translational mainboard driving device for moving the translational main board 4 relative to the beam 1, a rotating main board driving device for rotating the rotating main board 7 relative to the translational main board 4, an arm driving device for ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com