Shaping, enzyme deactivating and drying treatment process of selenium-enriched green tea

A selenium-enriched green tea and drying treatment technology, which is applied in the setting and drying of tea leaves, and in the field of tea processing, can solve the problems of affecting the quality of tea leaves in the tea processing process, the effect of flattening is not very good, and pressure control, so as to improve the setting The effect of finishing quality, drying effect is better, and drying time is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0055] The process of shaping, fixing and drying the selenium-enriched green tea comprises the following steps:

[0056] (1) Feed stage;

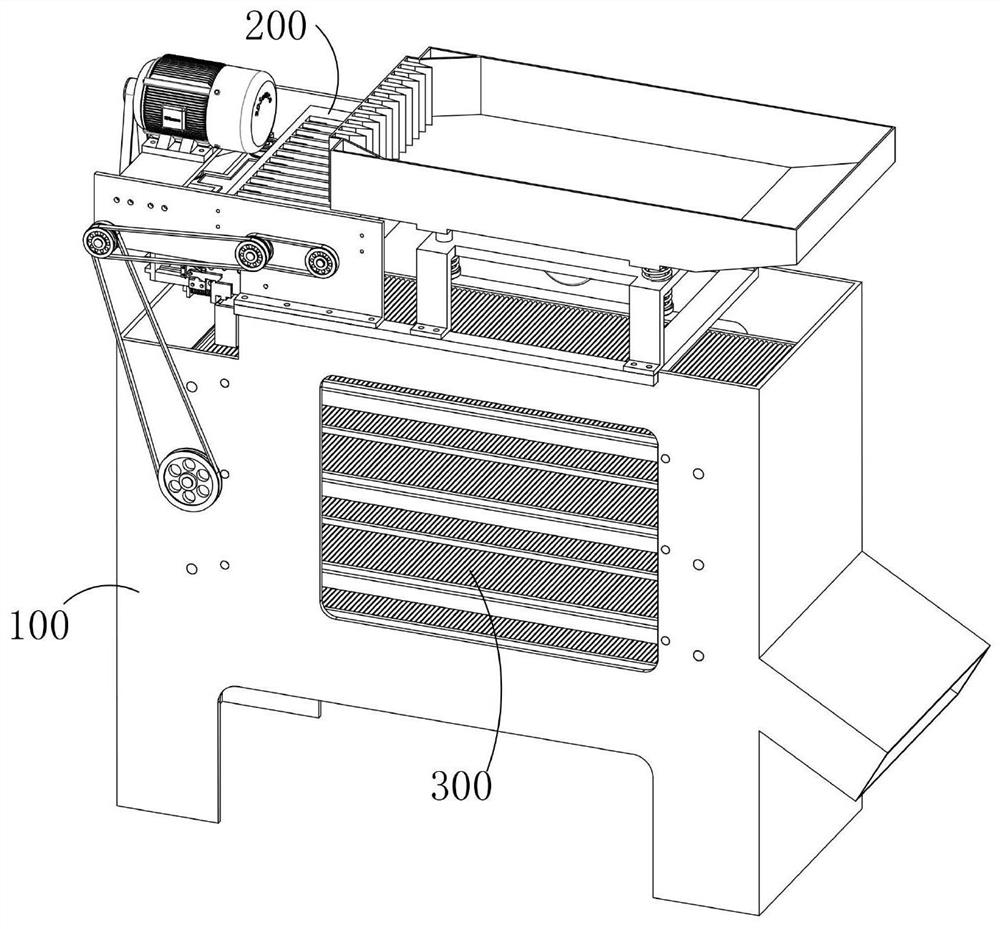

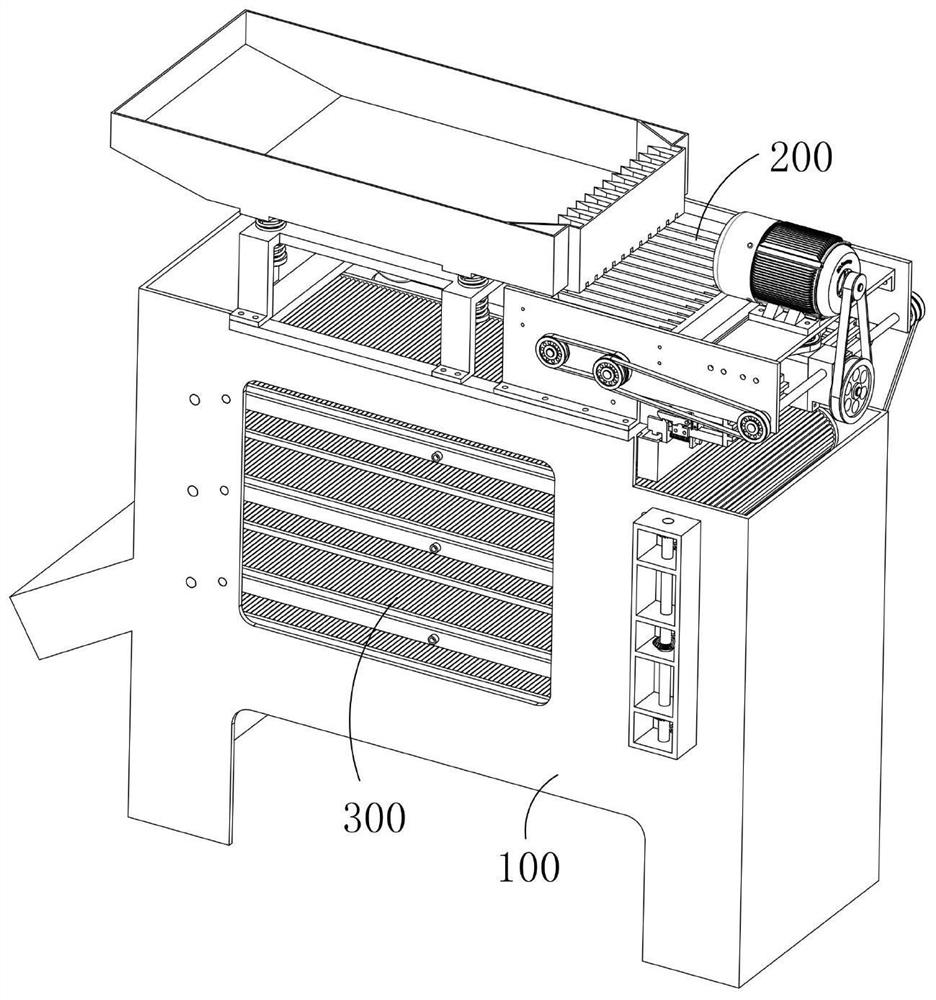

[0057] S1: The staff pours the tea leaves into the extrusion and fixing device 200 installed on the upper opening of the installation housing 100;

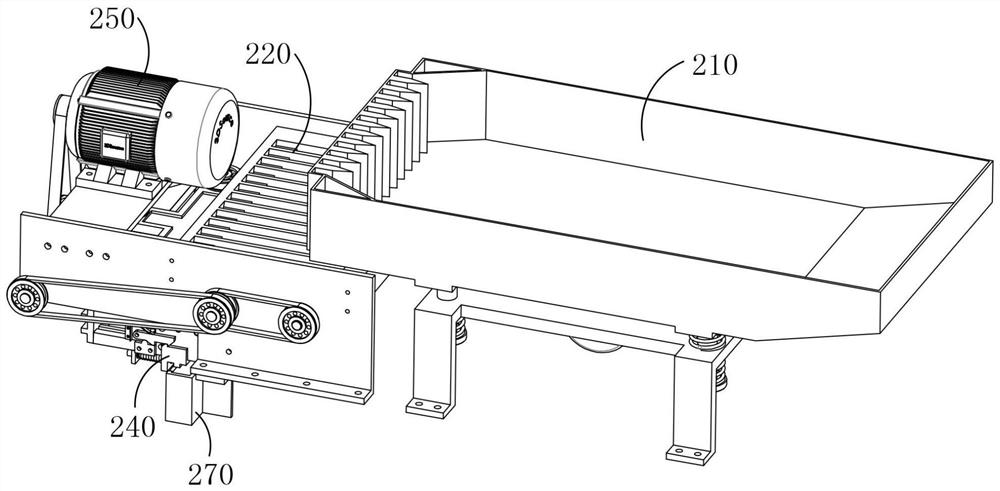

[0058] The worker pours the tea leaves into the quantitative conveying mechanism 210, and the quantitative conveying mechanism 210 runs and makes the tea leaves drop down into the feeding mechanism 220 with the leaf root facing down and the leaf tip facing upwards, and then, feeding The feeding mechanism 220 pulls the tea leaves and gradually drops them into the extruding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com