Wool washing machine with arched conveying belt and frictional face roller

A conveyor belt and friction surface technology, applied in the field of wool washing machine, can solve the problems of insufficient drying, affecting the effect of washing wool, sticking together, etc., and achieve the effect of simple and ingenious structure, preventing sticking, and increasing the conveying stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

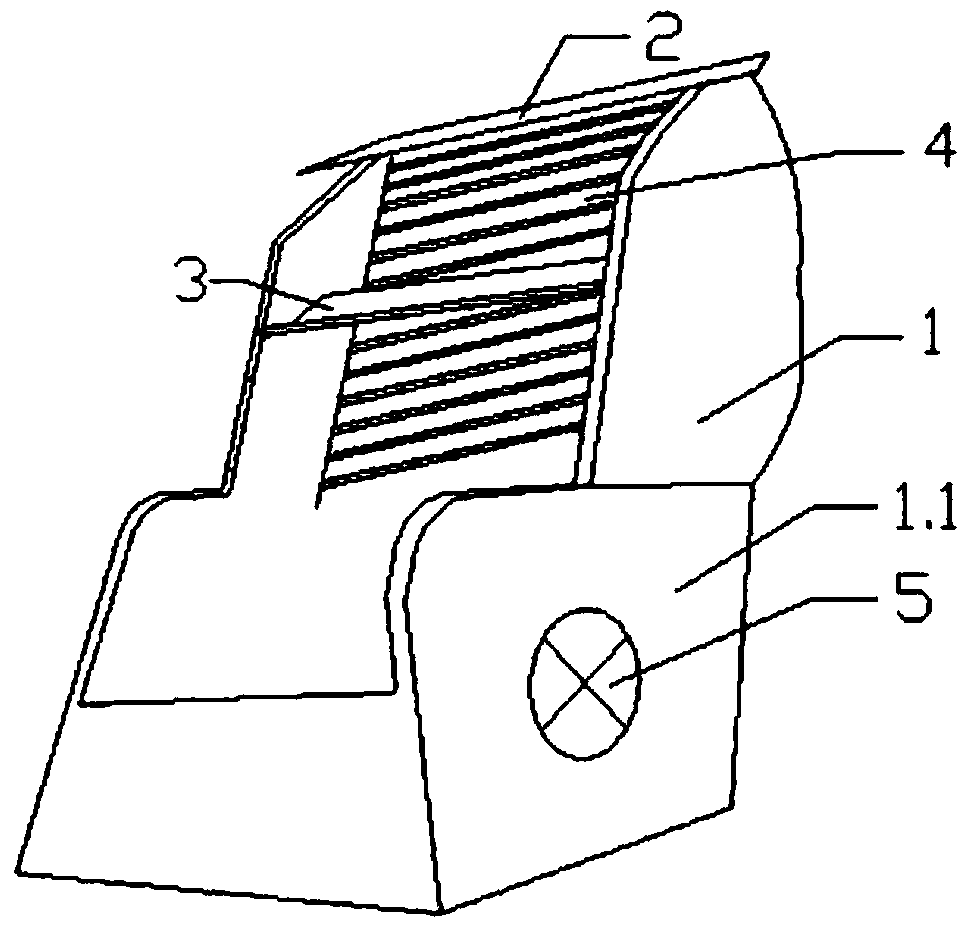

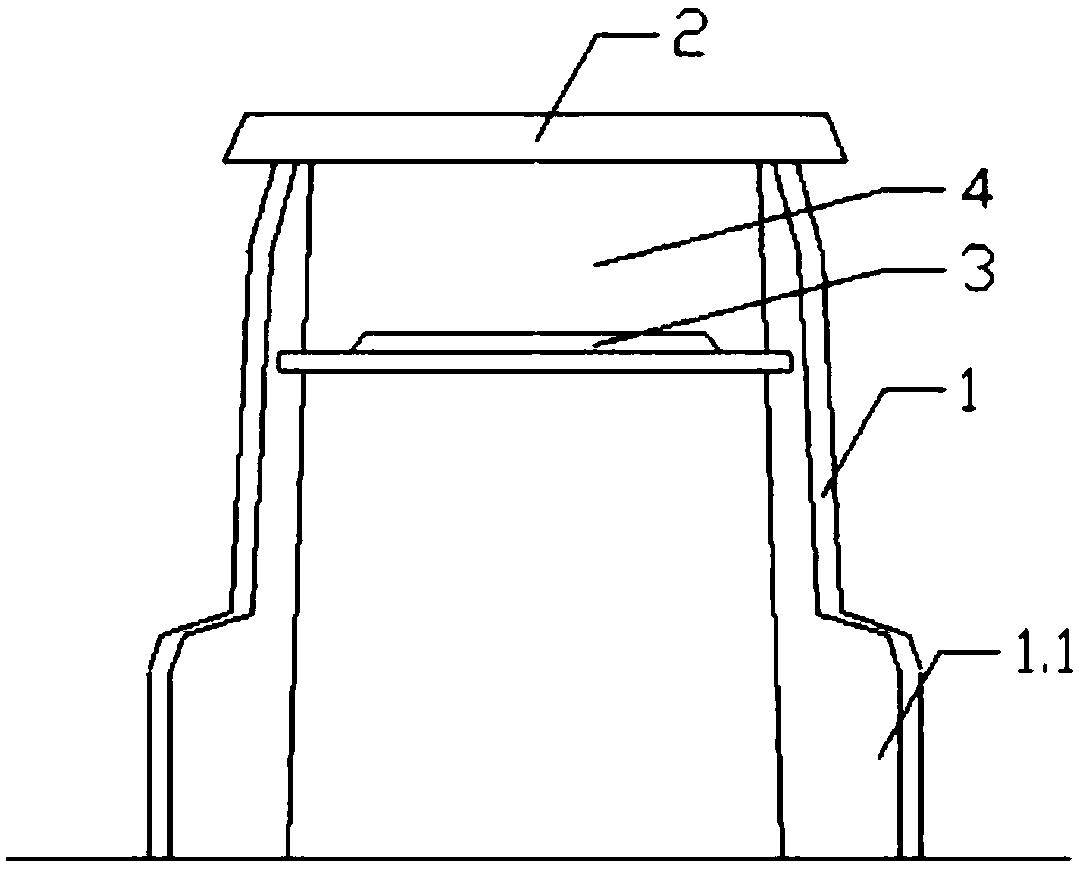

[0011] see figure 1 , 2 , the present invention relates to a wool scourer with an arched conveyor belt and friction surface rollers, which includes a frame 1 and a conveyor belt 4, the conveyor belt 4 is arranged on the frame 1, and the running track of the conveyor belt 4 is arched , the top of the frame 1 is provided with a cover 2, which can prevent the wool from drifting away during the conveying process, and the top of the frame 1 is provided with a paddle 3, and the side of the paddle 3 faces the conveyor belt 4, which can effectively loosen the sticky wool, The bottom of frame 1 is discharge bin 1.1, and the side of discharge bin 1.1 is provided with vibration motor 5, and vibration motor 5 loosens the wool of adhesion again. Wherein, the conveyor belt 4 includes a conveyor belt body 4.1 and a roller 4.2, and the surface of the roller 4.2 is provided with a friction surface 4.2.1, and this structure makes the conveying of the wool stable. The running track of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com