Spiral conveying type multi-layer marinated egg drying device and working method thereof

A technology of screw conveying and drying device, applied in drying, dryer, progressive dryer and other directions, can solve the problems of insufficient drying time, increase heat conduction distance, increase production cost, etc., to reduce heat conduction distance, The effect of ensuring product quality and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

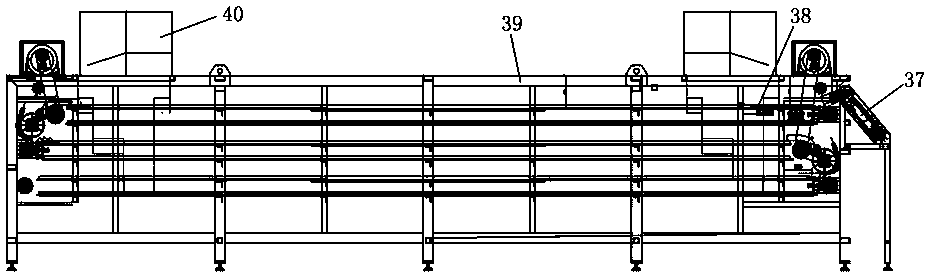

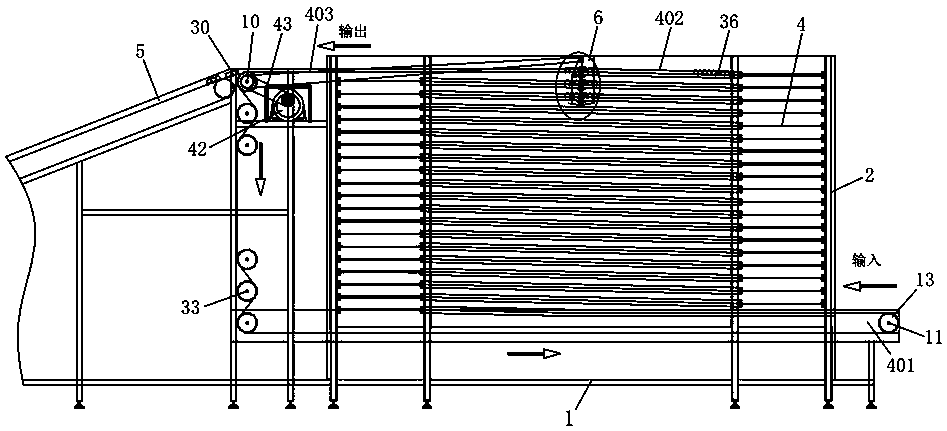

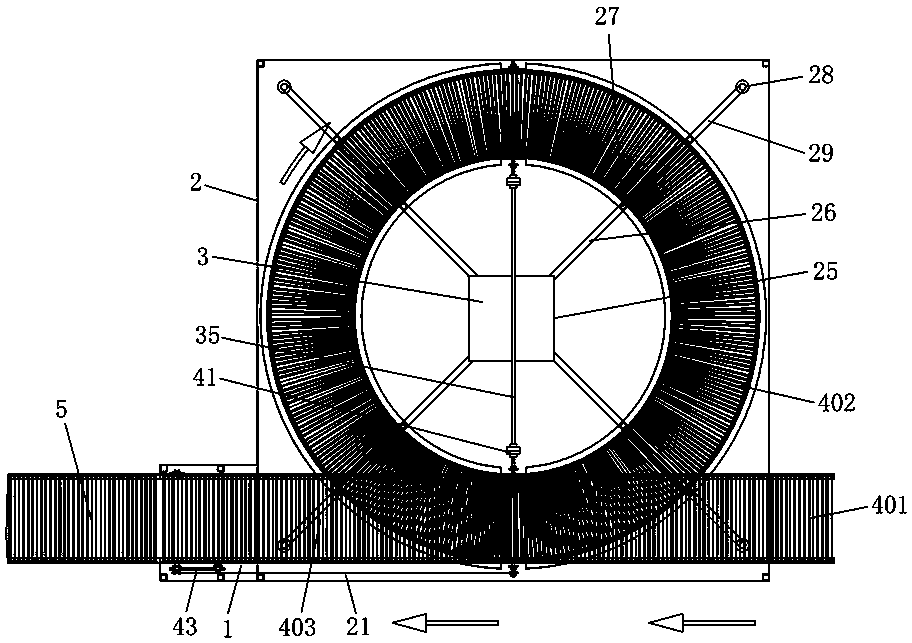

[0044] Embodiment one: if Figure 2-11 As shown, a screw conveying type multi-layer preserved egg drying device of the present invention includes a frame 1, a drying box body 2, an air intake and exhaust system 3, a screw conveying mechanism 4 and a preserved egg output mechanism 5, and the drying The box body 2 is arranged on the frame 1, and the screw conveying mechanism 4 is arranged in the drying box body 2. The screw conveying mechanism includes 4 input sections 401, a screw section 402 and an output section 403. The input section 401 is located in the drying box. At the bottom of the box body 2, the spiral section 402 is provided with an egg shaking mechanism 6 every 180° along the spiral direction from bottom to top, so that the marinated eggs can be lifted and lowered, and the output section 403 is located at the top of the drying box body 2; The stewed egg output mechanism 5 is arranged obliquely on the side of the drying box 2 and connected with the output section 403 ...

Embodiment 2

[0054] Embodiment two: if Figures 12 to 13 As shown, the difference between this embodiment and Embodiment 1 is that the egg shaker mechanism 6 includes an air nozzle 31, and the air nozzle 31 is arranged in parallel between two conveying rollers 9 adjacently arranged along the conveying direction, and the air nozzle 31 Connect with the air supply source through the air pipe 32, and blow air upwards through the air nozzle 31, so that the corned egg moves upward and separates from the conveying roller 9, and then stops the air supply, so that the corned egg falls under its own gravity, and the distance between the corned egg and the conveying roller The contact position is changed, which effectively prevents the marinated eggs from leaving scars after drying, and prevents the marinated eggs from being damaged due to bonding with the conveying roller.

[0055] The specific implementation process: (1) The hot air blower in the air intake and exhaust system is started, and the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com