Telescopic barreled paint conveying equipment

A kind of conveying equipment and telescopic technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of climbing conveying that cannot realize height difference, no sorting station, and only horizontal conveying, etc. To achieve the effect of convenient overall movement, convenient operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

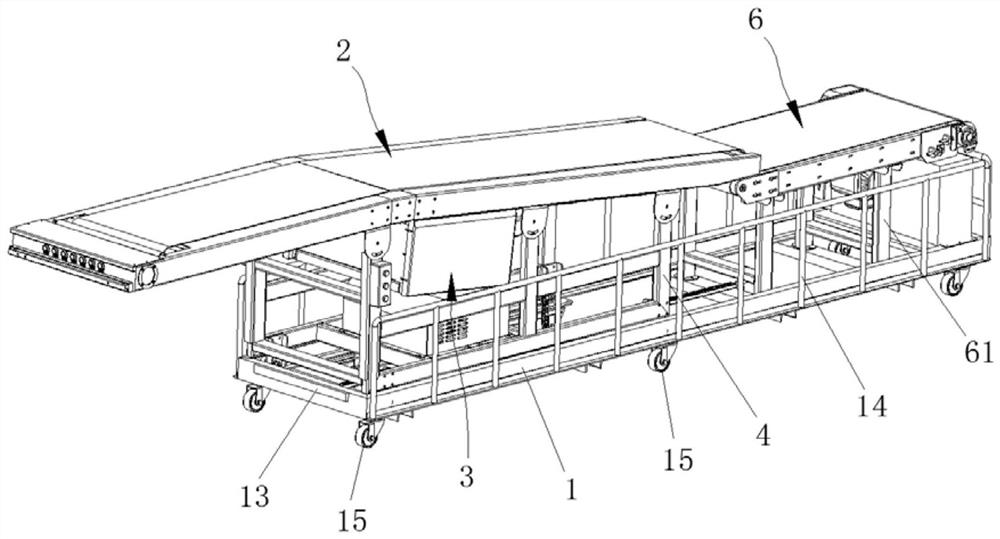

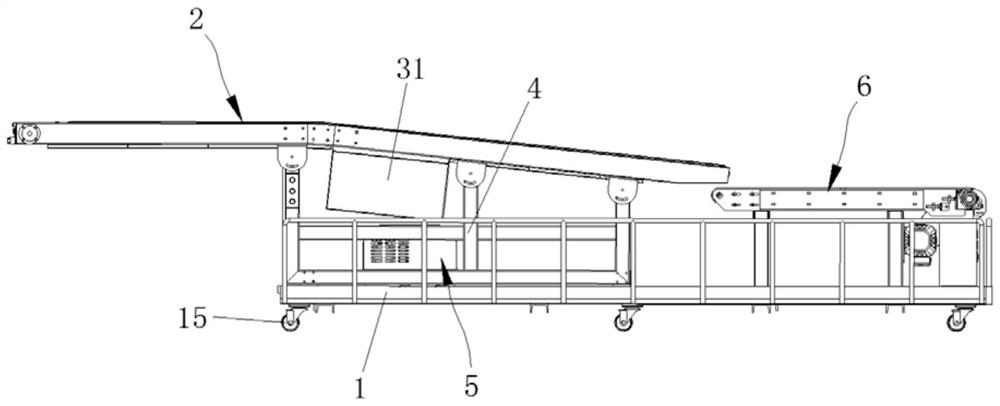

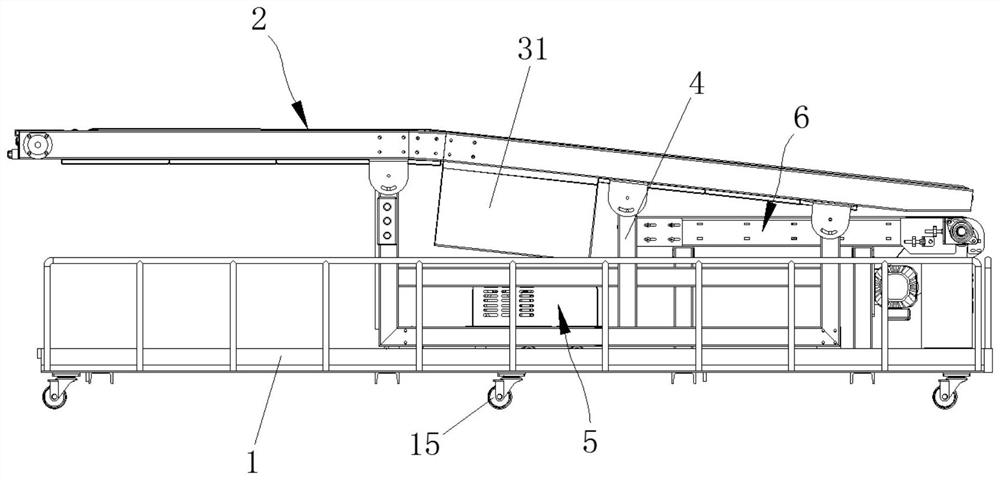

[0034] Please refer to Figure 1 to Figure 12 , Embodiment 1 of the present invention provides a telescopic barreled paint conveying equipment, including a track chassis 1, a climbing conveyor belt device 2, a translation carriage 4, a translation carriage translation drive device 5, an extension conveying line 6 and As for components such as the roller 7, the structure and working principle of each component will be described below.

[0035] The rollers 7 are rotatably mounted on the lower end of the translation carriage 4 through respective roller mounts 71 , and the translation carriage 4 is translatably installed on the track chassis 1 through the rollers 7 . Wherein, guardrails 14 may be provided on both outer sides of the track chassis 1 and one end close to the extended conveying line 6 .

[0036] Preferably, the track chassis 1 may include two translation tracks 11 and a plurality of first connecting bars 12, the translation tracks 11 are arranged parallel to each oth...

Embodiment 2

[0051] Please refer to Figure 13 , Embodiment 2 of the present invention provides another telescopic barreled paint conveying equipment, wherein, the structure of the paint conveying equipment in Embodiment 2 and the paint conveying The extended conveying line 6 in the second embodiment includes two installation side plates 62 and several electric drums 63, the two installation side plates 62 are installed on the fixed bracket 61, and the two installation side plates 62 are arranged parallel to each other and at intervals , the electric drum 63 is sequentially arranged between two installation side plates 62 along the length direction of the installation side plates 62 .

[0052] Of course, in other embodiments, the user can also set the extended conveying line as other types of conveying lines according to their own needs, which is not limited to this embodiment.

[0053] To sum up, the structure of the present invention is novel and the design is reasonable. Both the climb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com