Automatic online grabbing device of workpieces

A grabbing device and automatic technology, which is applied in the field of production and processing of online grabbing devices, hard alloys, and mechanical standard parts, can solve problems such as easy slipping, difficulty in judging the processing status of workpieces or products, and high labor intensity. Achieve the effect of solving high synchronization requirements, avoiding omissions and repeated processing, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention will be further described with reference to the accompanying drawings:

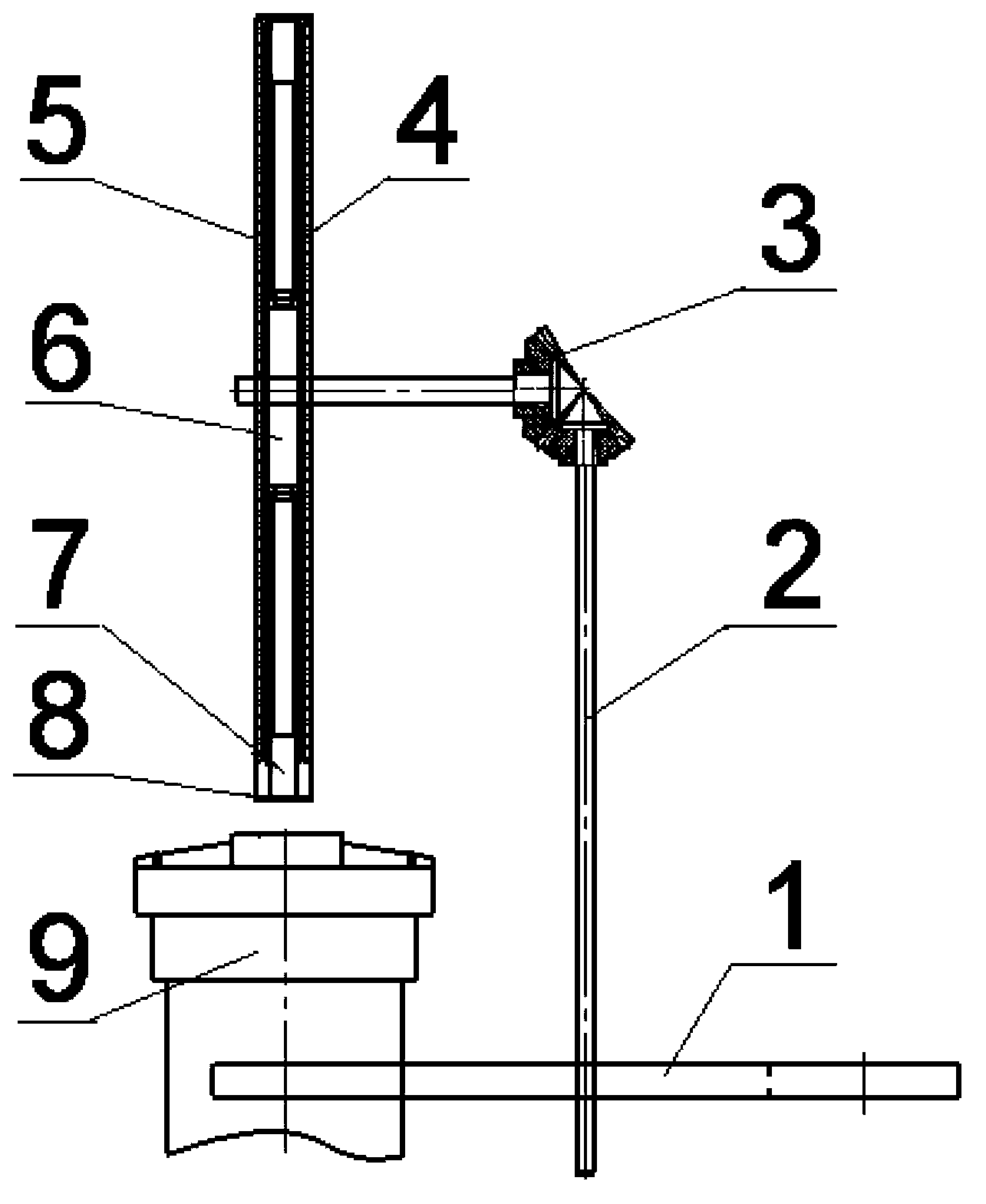

[0037] Such as figure 1 As shown, the present invention is composed of a fork wheel 1, an adjustable gear shaft 2, a gear set 3, a right cover plate 4, a left cover plate 5, a cam 6, a grab head, a spacer ring 8 and a station shaft 9. The shift fork wheel 1 meshes with the station shaft 9 and is connected to the gear set 3 through the adjustable gear shaft 2.

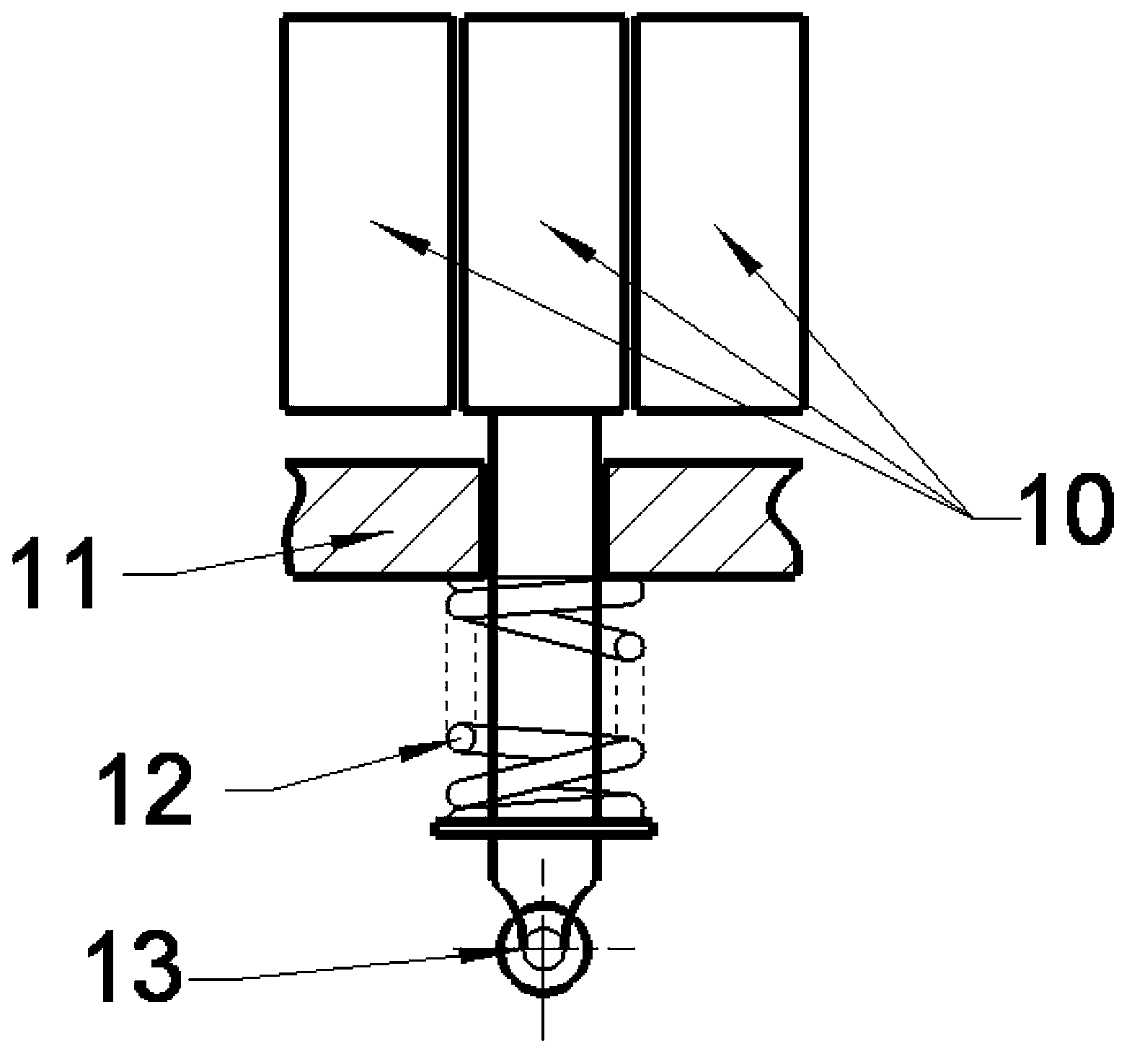

[0038] Such as figure 2 As shown, the grab head 7 is composed of a magnet group 10, a spring 12, and a roller 13. Among them, the cross section of the magnet group 10 is circular or square.

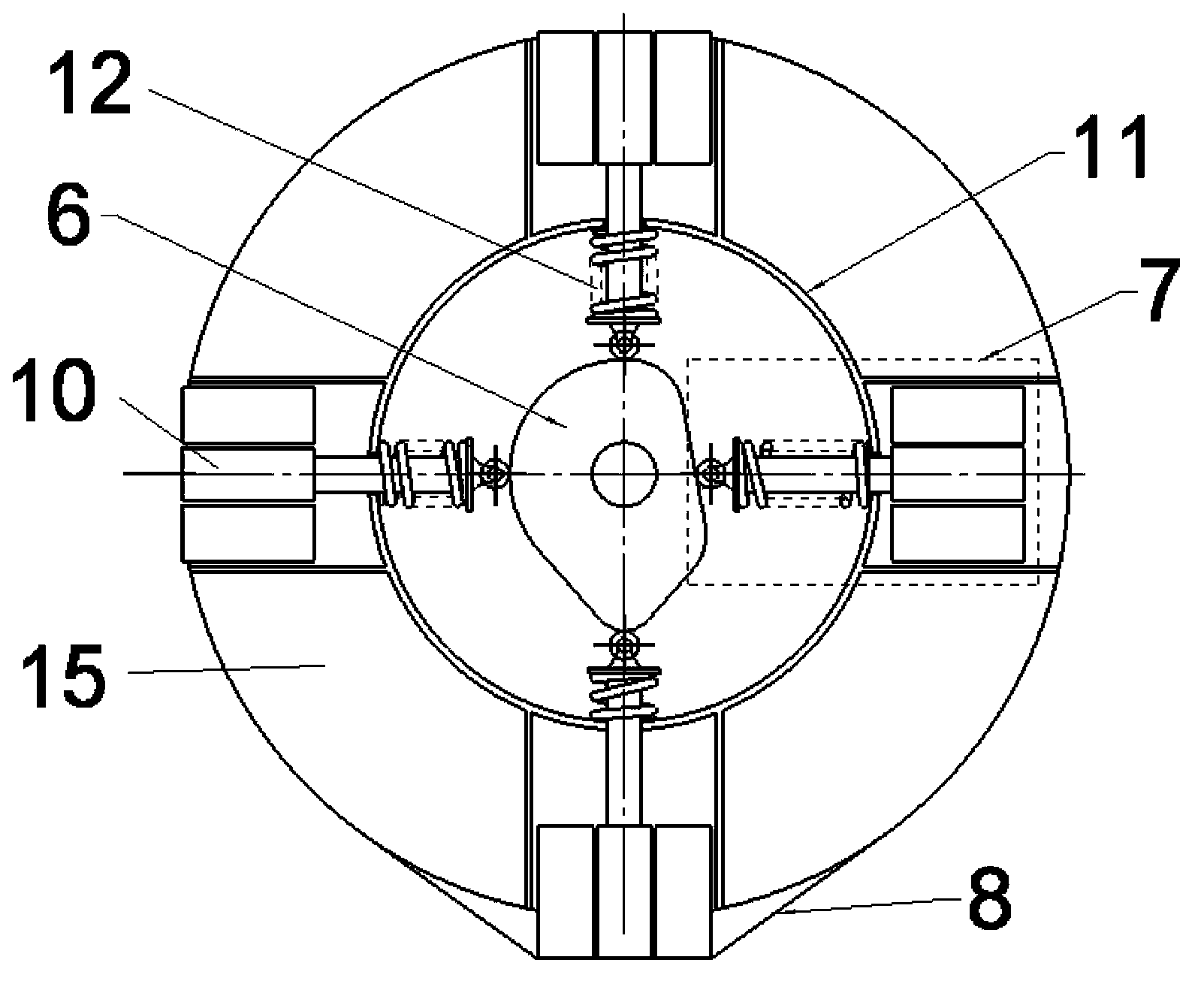

[0039] Such as image 3 As shown, the grab disk 15 is composed of 4 sets of grab heads 7, guide rings 11, cams 6, and spacer rings 8, which are connected to the gear set 3 through shafts.

[0040] Such as Figure 4 As shown, the working state of the grab plate 15 grabbing the workpiece 16.

[0041] Such as Figure 5 As shown, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com