Rapid feeding device for clothes production

A feeding device, fast technology, applied in the direction of lifting device, lifting frame, etc., to achieve the effect of simple structure, large load capacity and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

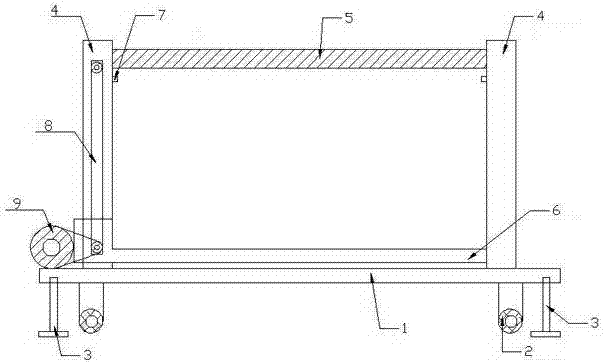

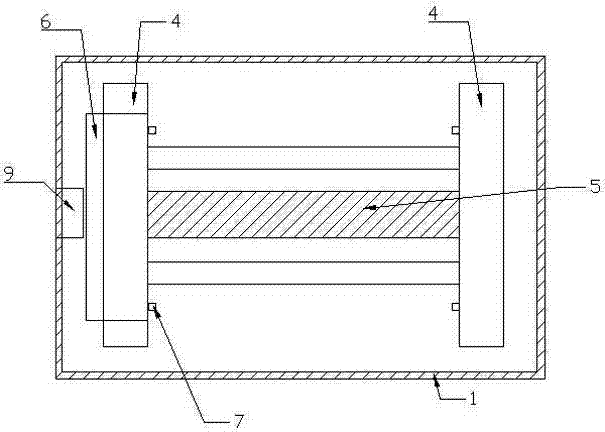

[0019] further as figure 1 As shown, when in use, the feeding device is moved to the position of the feeding port of equipment such as loose cloth machine or cloth inspecting machine through the universal wheel 2, and the feeding device is positioned and limited by the support seat 3, and then the cloth is manually transported to the load plate frame 6, and then control the driving motor 9 to drive the transmission mechanism 8 connected with the load plate frame 6 to transport the cloth upwards, and when it reaches the predetermined position, it will complete a feeding process when unloading; wherein in this feeding device The limit block 7 can be adjusted according to the height of the processing machine platform to the cloth, so as to adapt to the actual use requirements.

[0020] The feeding device has a stable working state, is suitable for various garment production environments, and meets the needs of garment production enterprises to improve work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com