Reciprocating push plate wind turbine

A wind turbine and push plate technology, which is applied to wind turbines, wind energy power generation, engines and other directions, can solve the problems of low wind energy utilization coefficient, inconvenient movement, fixed and no longer movable, etc., and achieves high wind energy utilization rate and wind energy utilization. High coefficient, easy to use and move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

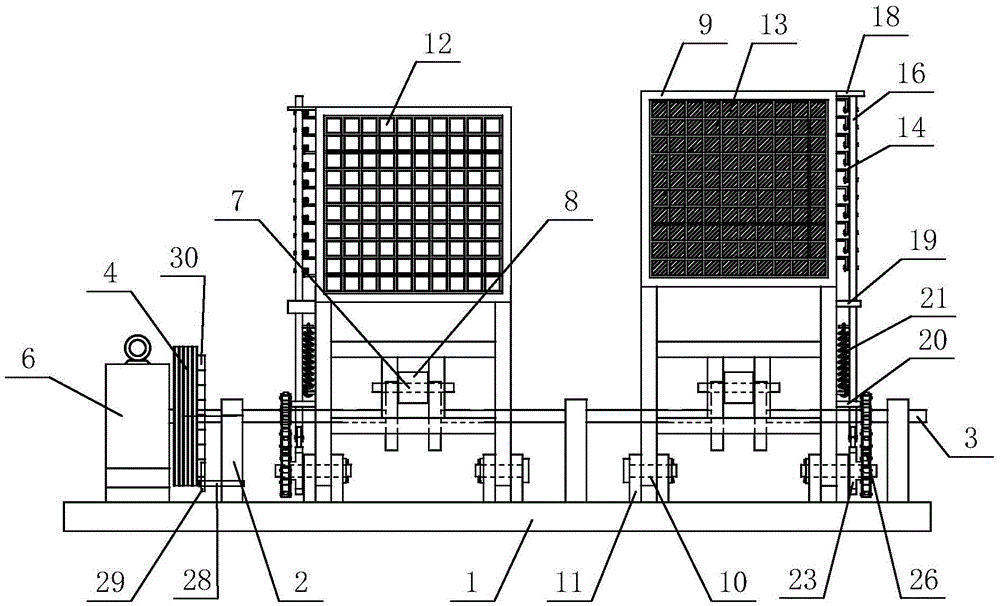

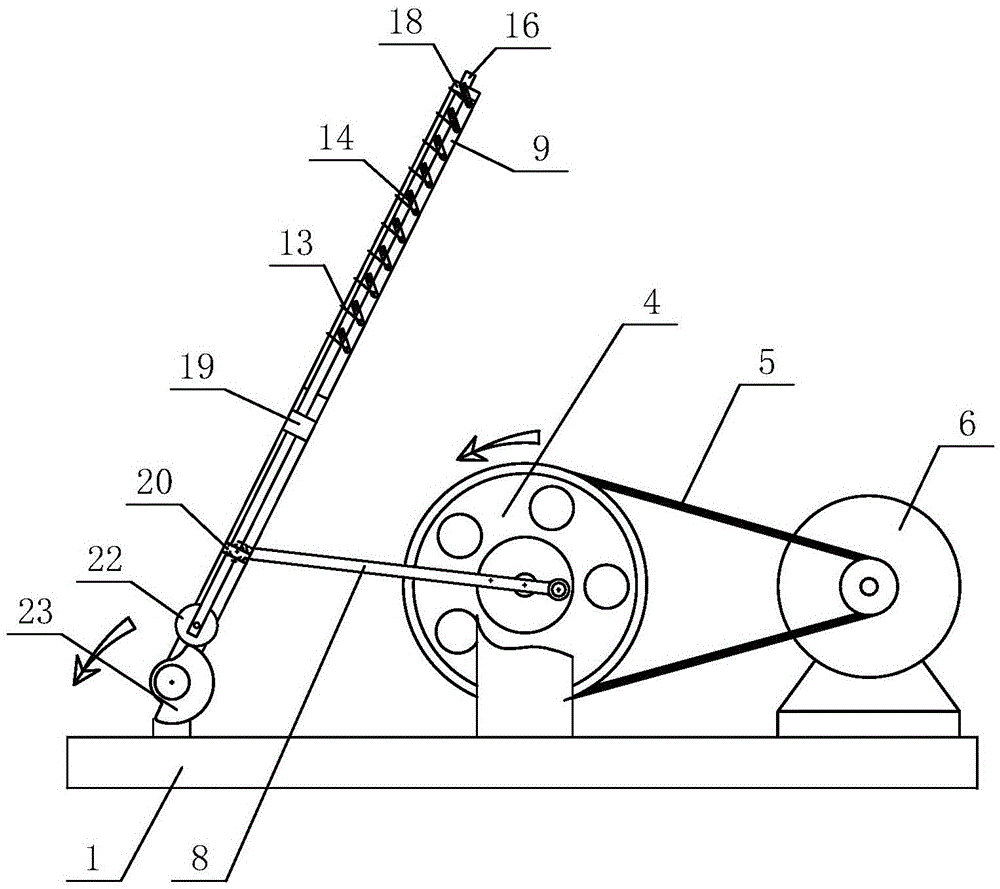

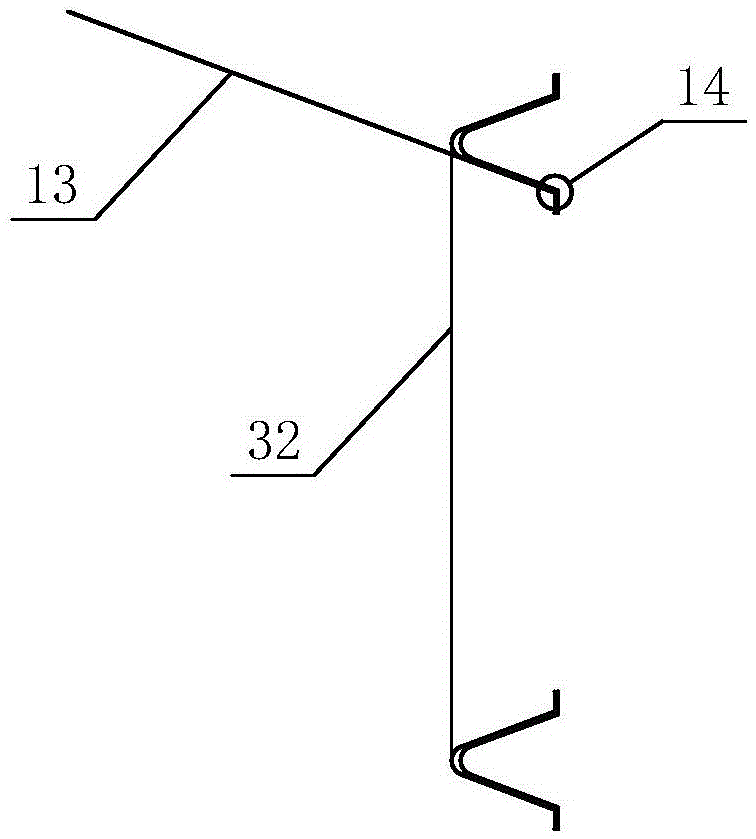

[0019] In order to clearly illustrate the technical characteristics of this solution, the following describes the present invention in detail through specific implementations and in conjunction with the accompanying drawings.

[0020] Such as Figure 1-8 As shown, a reciprocating push-plate wind power generator includes a base 1, a crankshaft 3 is movably installed on the base 1 through a number of crankshaft pads 2, and one end of the crankshaft 3 is fixedly connected to a large crankshaft pulley 4, The seat 1 is provided with a one-way rotating device that is matched with the large crankshaft pulley 4, and the large crankshaft pulley 4 is connected to the pulley on the input shaft of the generator 6 provided on the base 1 through the V-belt 5; At least two crank arms 7 with the same turning diameter are arranged at the upper interval, and each crank arm 7 is arranged in a staggered and uniform manner along the circumference of the crankshaft 3. On the base 1 on one side of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com