Preparation method of multiferroic bismuth ferrite cubic nanoparticles

A bismuth ferrite and multiferroic technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of easy control, easy promotion, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

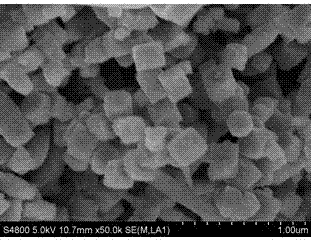

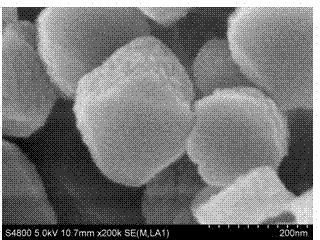

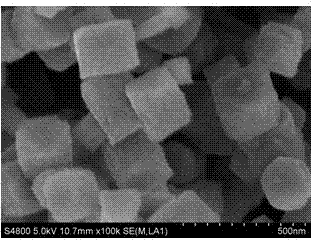

Image

Examples

Embodiment Construction

[0021] Using high-purity Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 ·5H 2 O, respectively as Fe source, Bi source, according to 4.0 g Fe(NO 3 ) 3 9H 2 O , 4.85 g Bi(NO 3 ) 3 ·5H 2 The mass ratio of O was respectively configured into 20ml solutions, and the reaction solution was transferred to a hydrothermal reaction kettle with a polytetrafluoroethylene liner to fully dissolve the reactants under magnetic stirring conditions. Weigh 5.05 g of KOH mineralizer to prepare a 20mol solution. Slowly pour the configured potassium hydroxide solution into the stirring reaction kettle, and continue stirring for 30 min under magnetic stirring conditions. After the stirring, the reaction kettle was sealed, placed in a high-temperature drying oven at 200°C for 6 hours, taken out, and cooled to room temperature naturally. After cooling, take out the reaction kettle and pour the reacted solution into a clean beaker, rinse with deionized water, and ultrasonically oscillate for about one minut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap