A variable embossing machine

A variable embossing and variable embossing machine technology, applied in textiles and papermaking, fabric surface trimming, thorn patterns, etc., can solve problems such as embossing process limitations, inconvenient production, and cumbersome production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

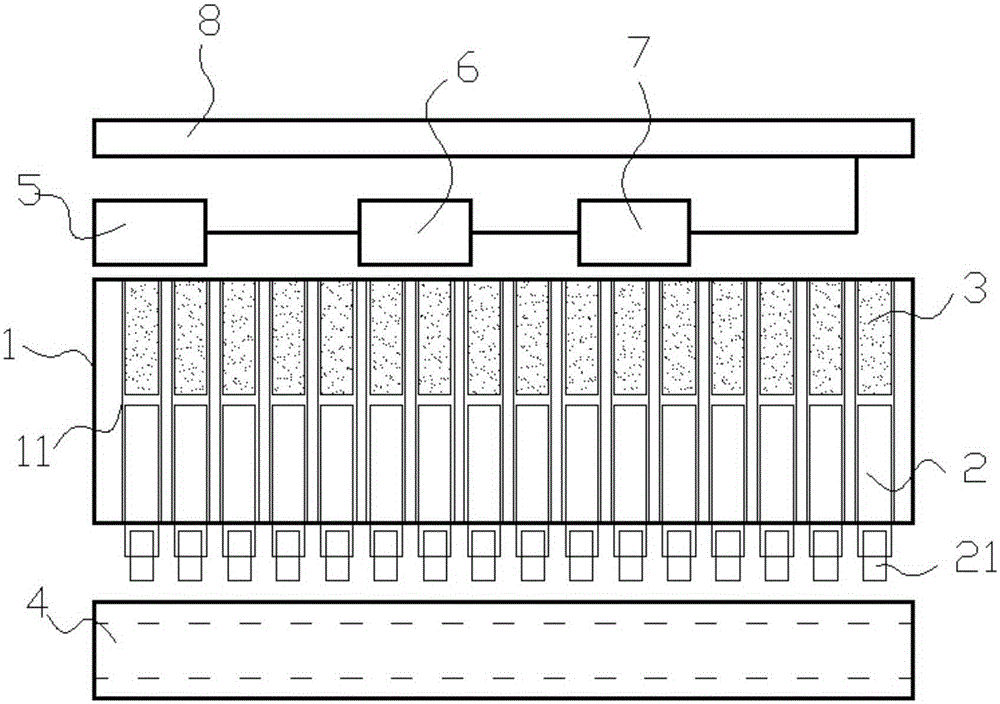

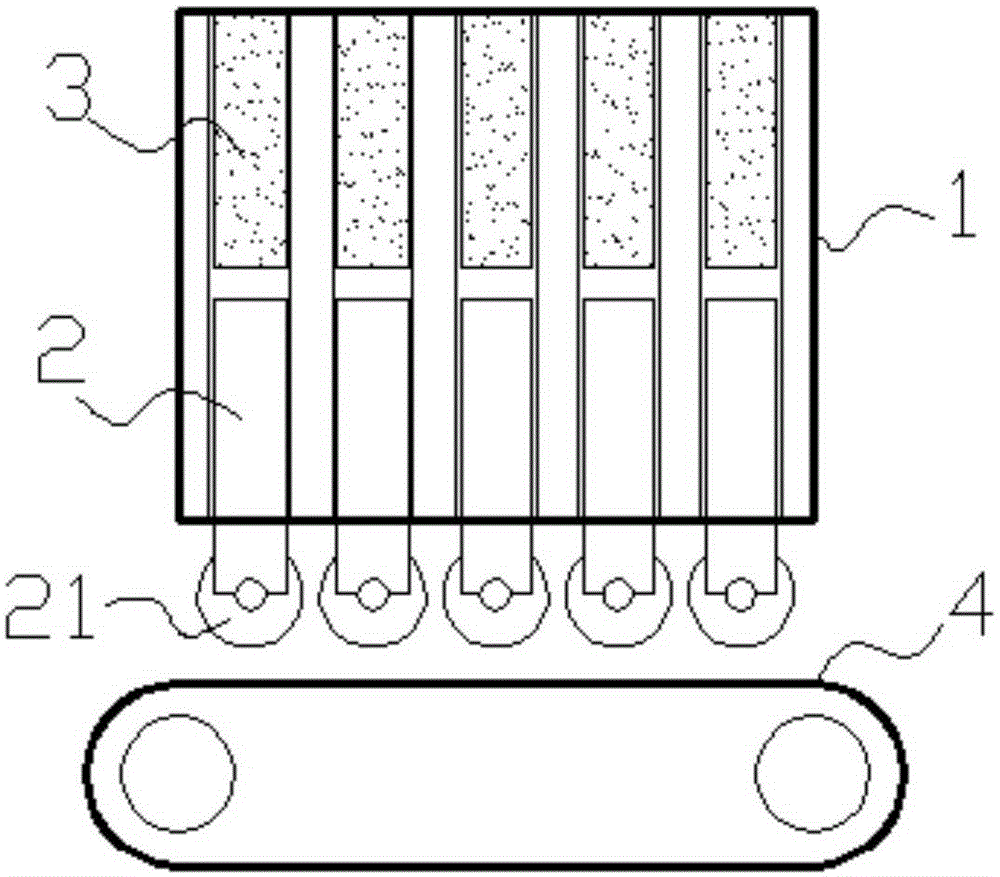

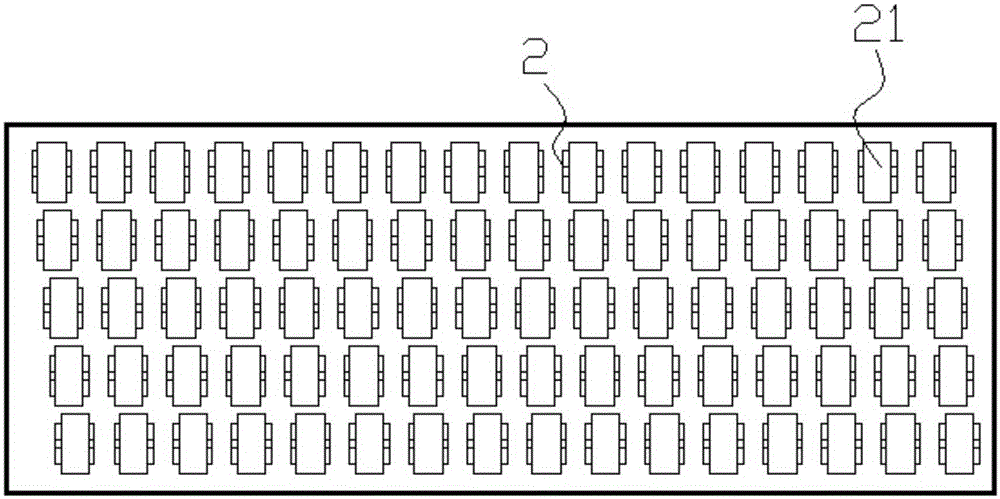

[0014] exist Figure 1 to Figure 3 In the illustrated embodiment, the variable embossing machine includes a conveyor belt 4 and a flower wheel set; the conveyor belt 4 for conveying cloth is located directly below the flower wheel set, and the conveyor belt 4 is made of rubber material. Its outer surface array is covered with thin iron sheets; during the embossing process of the cloth, the ultrasonic wave transmitted by the flower wheel (2) will also heat the conveyor belt (4), this structure can effectively prevent the conveyor belt (4) from being damaged and extend the The service life of the conveyor belt (4); the flower wheel group includes a flower wheel base 1 and a flower wheel 2 made of magnetic material; the flower wheel base 1 is provided with an array of seat holes 11 in a rectangular arrangement , in particular, there are 16 seat holes 11 in each row perpendicular to the cloth conveying direction in the seat hole 11 array, 5 rows in total; there is a misalignment b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com