Printing screen for ceramic tile decoration and manufacturing method thereof

A production method and printing screen technology, applied in printing, printing plate, printing plate preparation, etc., can solve the problems of limited thickness, lack of change, and influence on the effect of the mesh cloth, and achieve good decorative effect and distinctive product features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The substantive features and significant progress of the present invention will be described below in conjunction with specific implementation forms and accompanying drawings. It should be understood that these embodiments are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

[0025] In order to solve the various defects in the preparation of ceramic tiles with concave-convex effect in the prior art, the present invention provides a printing screen printing method for ceramic tile decoration, which includes: laser engraving the polyurethane elastomer to form the desired pattern ; Using a screen frame to reinforce the polyurethane elastomer to make a screen. The invention realizes the concave-convex effect of imitating the mold through planar printing of thick plates.

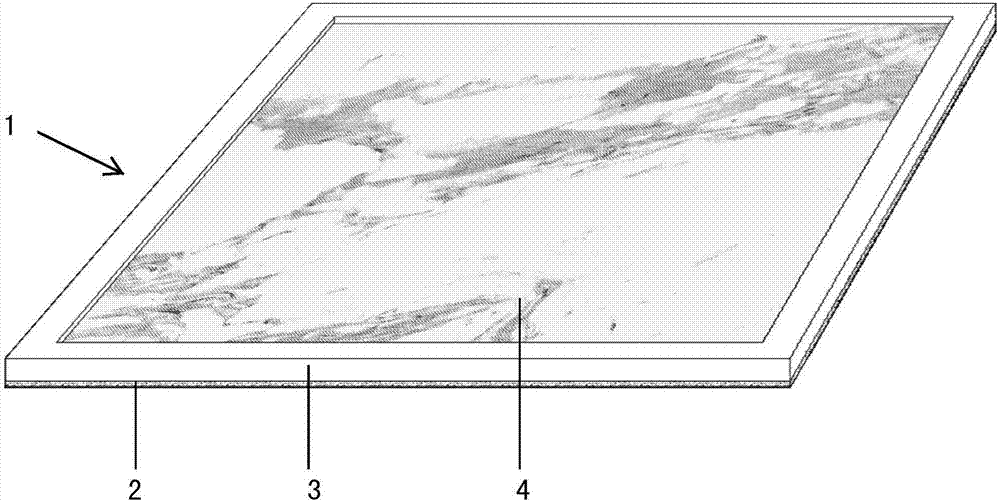

[0026] figure 1 A schematic structural view of the printing screen 1 produced according to the method of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com