Pre-treatment method for reducing crack on semi-rigid base asphalt pavement

A technology of semi-rigid base and asphalt pavement, which is applied in the direction of roads, roads, road repairs, etc., to achieve the effect of improving pressure resistance and service life and reducing reflective cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

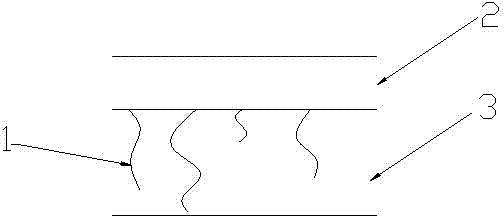

[0017] A pretreatment method for reducing semi-rigid base asphalt pavement cracks, including the steps: after the base layer 3 is cured for 1 day, the base layer 3 is vibrated and rolled multiple times with a vibratory roller with a wheel load of more than 13 tons. It is 3.2km / h, and the compacted area of the base layer 3 accounts for more than 90% of the total area of the base layer 3. The stiffness test is performed every time the base layer 3 is pressed. When the stiffness of the base layer 3 drops to 40% before the compaction, the compaction is stopped, and then immediately Cover with a film and continue to sprinkle water for curing for more than seven days to restore the stiffness of the base layer 3. At the same time, the mesh micro-cracks can be effectively self-healed through hydration and other reactions, which not only guarantees the required stiffness of the road surface, but also passes through the base layer. Micro-cracks can effectively control the generation o...

Embodiment 2

[0019] A pretreatment method for reducing semi-rigid base asphalt pavement cracks, including the steps: after the base 3 has been cured for 2 days, the base 3 is vibrated and rolled multiple times with a vibratory roller with a wheel load of more than 13 tons. It is 4km / h. The area of the base layer 3 being rolled accounts for more than 90% of the total area of the base layer 3. The stiffness test is performed every time the base layer 3 is pressed. When the rigidity of the base layer 3 drops to 50% before rolling, stop rolling, and then use it immediately. Cover with film and continue to sprinkle water for curing for more than seven days to restore the stiffness of the base layer 3. At the same time, the meshed micro-cracks can be effectively self-healed through hydration and other reactions, which can not only ensure the required stiffness of the road surface, but also pass through the base layer. Cracks can effectively control the generation of reflection cracks on the ro...

Embodiment 3

[0021] A pretreatment method for reducing semi-rigid base asphalt pavement cracks, including the steps: after the base 3 has been cured for 3 days, the base 3 is vibrated and rolled multiple times with a vibratory roller with a wheel load of more than 13 tons. It is 4.8km / h, the area of the base layer 3 being rolled accounts for more than 90% of the total area of the base layer 3. The rigidity test is performed every time the base layer 3 is pressed. When the rigidity of the base layer 3 drops to 60% before the rolling, the rolling is stopped, and then immediately Cover with a film and continue to sprinkle water for curing for more than seven days to restore the stiffness of the base layer 3. At the same time, the mesh micro-cracks can be effectively self-healed through hydration and other reactions, which not only guarantees the required stiffness of the road surface, but also passes through the base layer. Micro-cracks can effectively control the generation of reflective c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com