Laminated slab shear wall with exposed fastening steel bars and its connection method

A shear wall and laminated board technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of being unsuitable for high-rise buildings, unfavorable production and application, low structural strength, etc., to reduce the consumption of turnover materials and sporadic materials, The effect of eliminating unsafe factors and saving construction funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

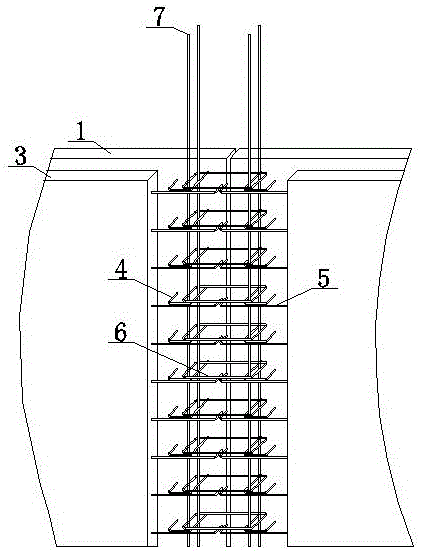

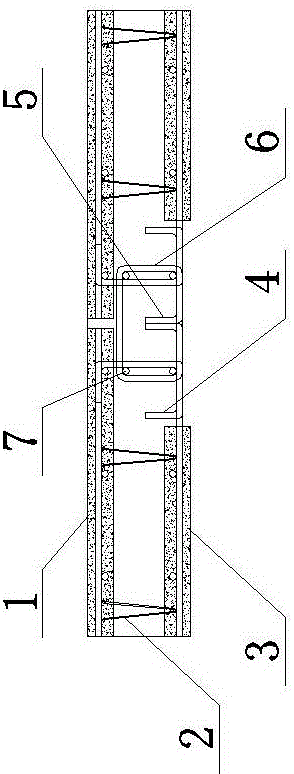

[0016] A laminated slab shear wall with exposed buckled steel bars, which comprises: a precast concrete outer slab 1, a precast concrete inner slab 3, the precast concrete outer slab has a group of outer slab internal steel bars 4 , the prefabricated concrete inner slab has an inner steel bar 5, the precast concrete outer slab and the precast concrete inner slab are connected by a connecting lattice steel bar 2, and the inner steel bar of the outer slab Annular closed stirrups 6 are placed on the internal reinforcement of the inner layer plate, and stressed steel bars 7 are inserted into the four corners of the annular closed stirrups.

Embodiment 2

[0018] According to the laminated plate shear wall with exposed buckled steel bars described in Embodiment 1, the internal steel bars of the outer layer plate protrude to the inside of the shear wall to form a 90-degree bent shape, and the inner layer of the inner layer plate The steel bars protrude to the side of the shear wall and are made into a 90-degree bent shape.

Embodiment 3

[0020] A method for connecting laminated slab shear walls with exposed buckled steel bars described in Embodiment 1 or 2, the prefabricated concrete outer layer slab with the single-layer horizontal and vertical reinforcement mesh of the shear wall as the skeleton, the connecting lattice steel bar, and the The single-layer horizontal and vertical reinforcement mesh of the shear wall is a prefabricated concrete inner layer slab, the outer layer and the inner layer are connected by connecting lattice steel bars, and the size of the outer layer is on one side or two sides or three sides or four sides, etc., which are larger than the corresponding sides of the inner layer plate, the internal steel bars of the outer layer plate protrude to the inside of the shear wall, and are made into a 90-degree bend shape, and the internal steel bars of the inner layer plate extend toward the shear wall The side protrudes and is made into a 90-degree bent shape, and the outer and inner panels ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com