Integrated engine oil lubricating module system and engine oil filtering lubricating method thereof

A modular system, oil filtration technology, applied in the pressure lubrication of lubricating pumps, engine lubrication, lubricating parts, etc., can solve the problems of difficult maintenance, low reliability, large engine volume and weight, etc., and achieve disassembly, installation and maintenance. Convenience and simplicity, good energy saving and environmental protection performance, and the effect of reducing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below with reference to the drawings and embodiments.

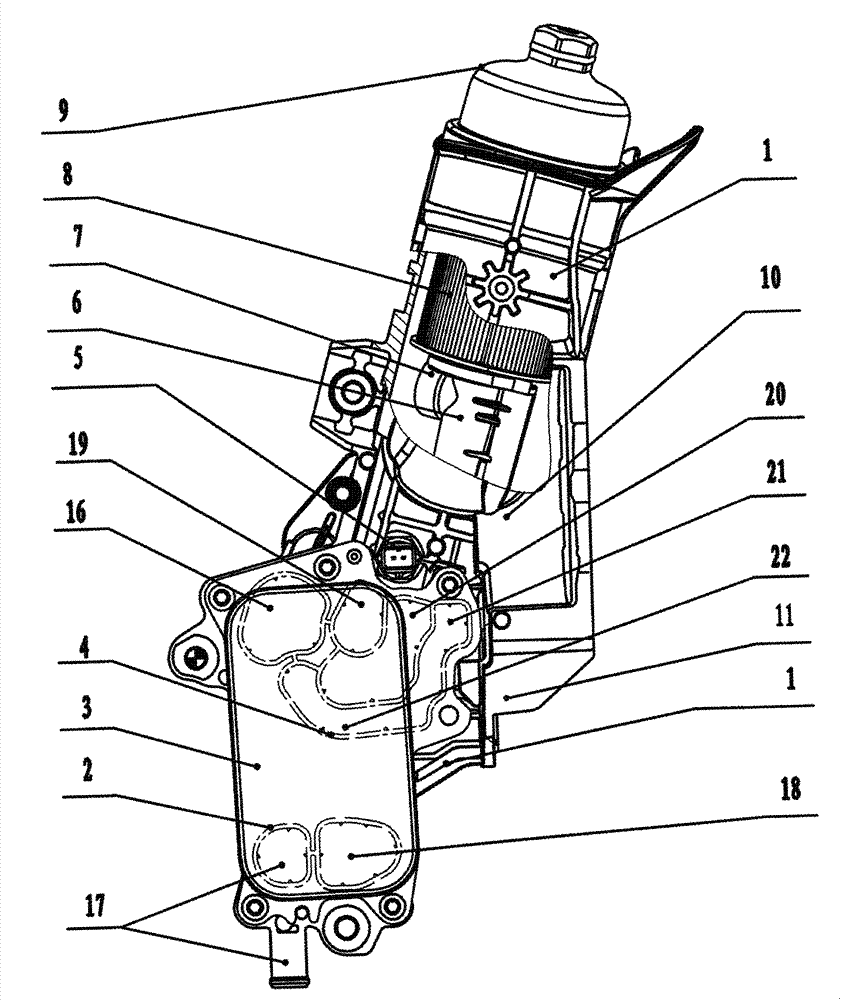

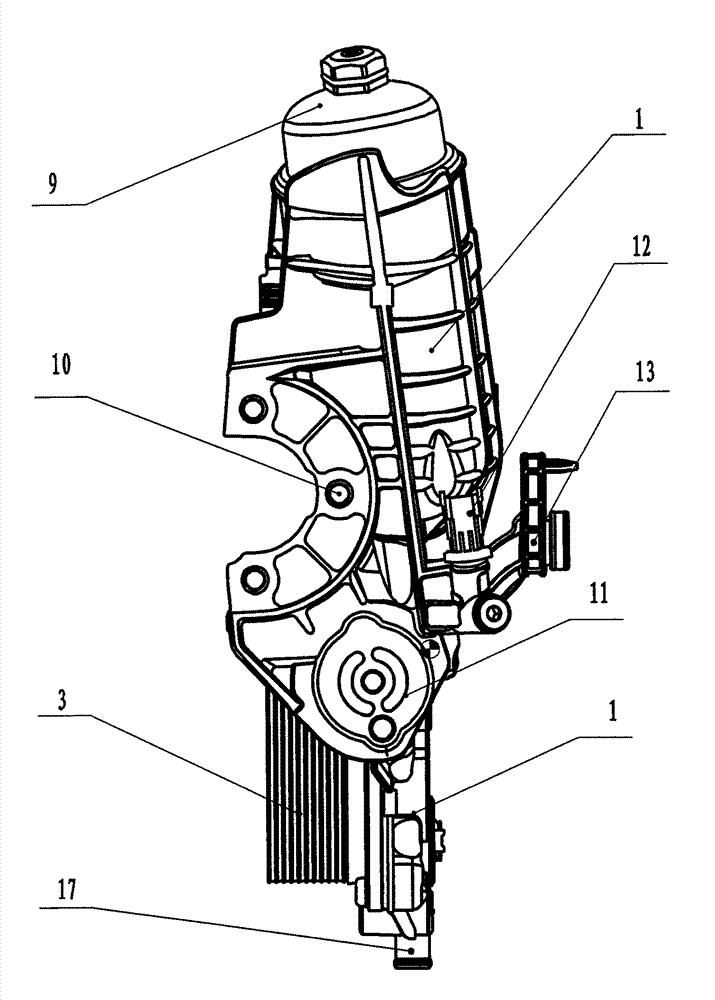

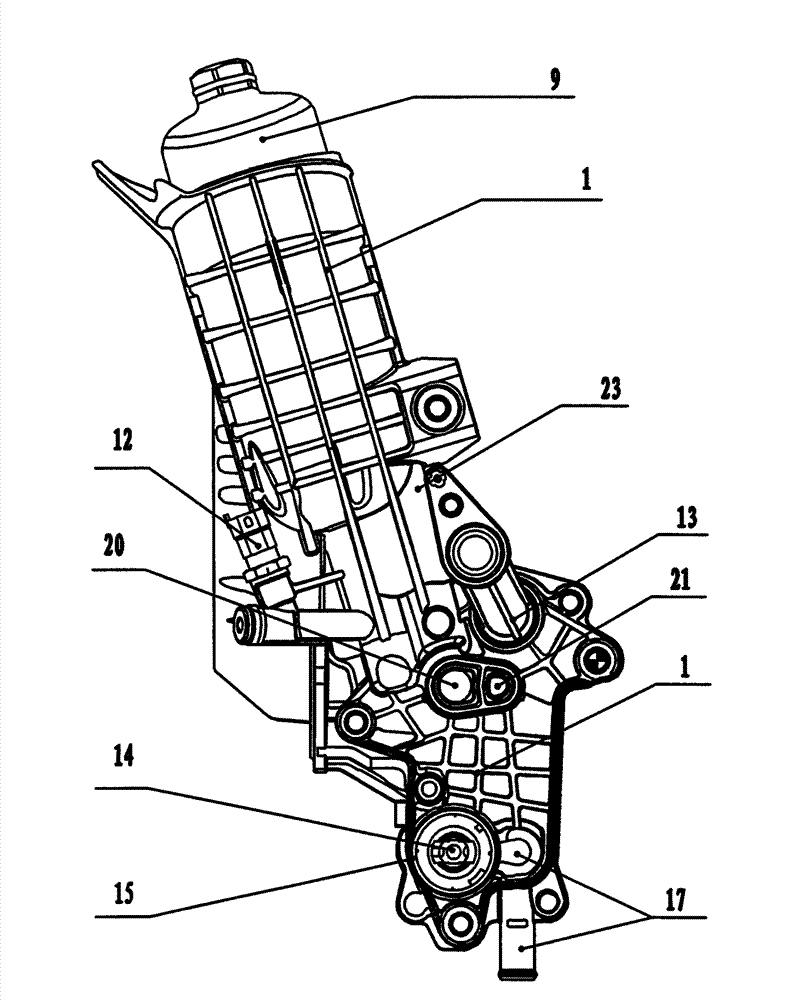

[0013] refer to Figure 1 to Figure 4 It can be seen that the present invention is applied to the integrated oil lubrication module system of the engine, which includes a filter element 8 and an oil cooler 3, and the filter element 8 (on the top, including the end cover) is set in the module housing through the filter element bracket 6 (on the bottom) 1 (that is, the upper part of the module housing 1 has a box-like structure), the oil cooler 3 is mounted on the module housing 1 (middle and lower parts), and the module housing 1 has a The coolant inlet 16, the coolant outlet 17, and the engine oil inlet 18 communicated with the cooler 3, and the module housing 1 has an engine oil filter inlet 19 (and an engine oil filter) respectively communicated with the filter element 8 and the filter element bracket 6 respectively. Clear inlet pipeline 23), engine oil f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com