Tide level self-adaption device of vibration floater wave power generation device

A power generation device and wave energy technology, which is applied in the direction of ocean energy power generation, hydropower generation, engine components, etc., can solve the problems of limit switch damage, strength reduction, structural deformation, etc., and achieve reduced manufacturing costs, low use and maintenance costs , simple structure and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

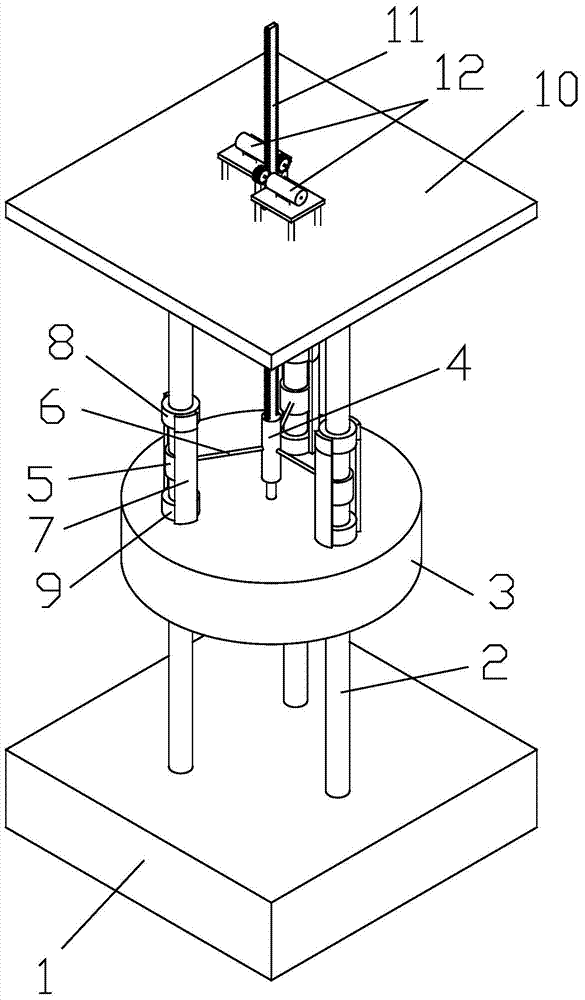

[0021] The tidal level adaptive device of the oscillating buoy wave energy generating device of the present invention, such as figure 1 As shown, the oscillating buoy wave energy generating device includes a submersible buoy 1, a guide rod 2, a float 3, a hydraulic cylinder 4, and a sleeve 5. The guide rod 2 is installed on the submersible buoy 1, and both the float 3 and the sleeve 5 are set on the guide rod. 2, the cylinder body of the hydraulic cylinder 4 is fixedly connected to the sleeve 5 through the support arm 6, and the piston rod of the hydraulic cylinder 4 is fixedly connected to the float 3.

[0022] The tide level adaptive device includes a wave height adjustment frame and a damping mechanism.

[0023] The wave height adjustment frame is fixed on the float 3, including the connection plate 7 and the upper limit sleeve 8 and the lower limit sleeve 9 fixed on the connection plate 7, and the upper limit sleeve 8 and the lower limit sleeve 9 are all set on the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com