Retarder with improved bearing lubrication

A retarder and machine technology, applied in the field of hydraulic machines, can solve the problem that the oil cannot reach the bearing parts reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

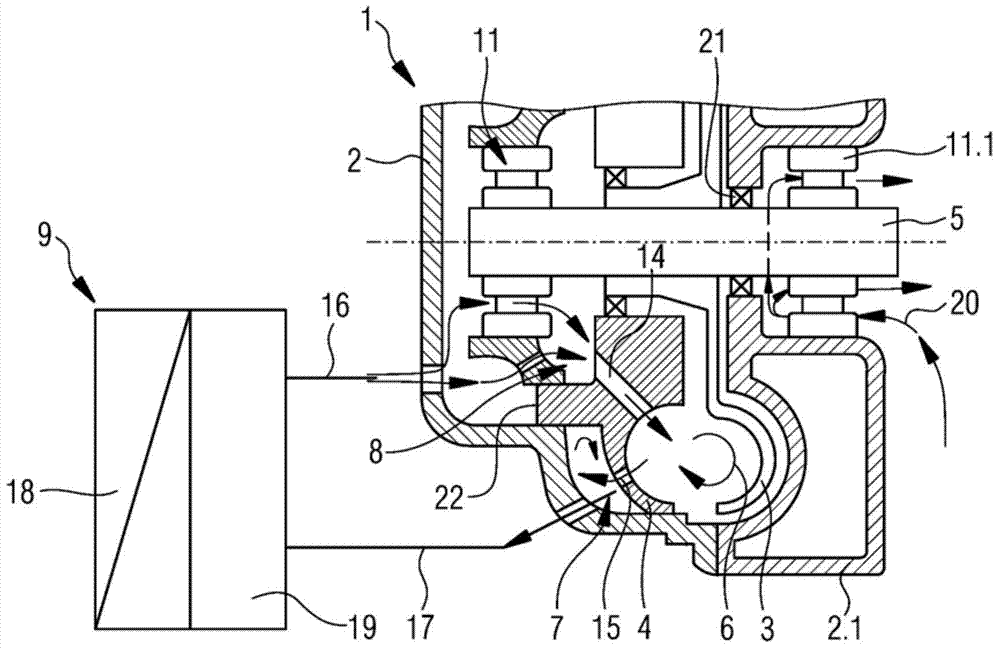

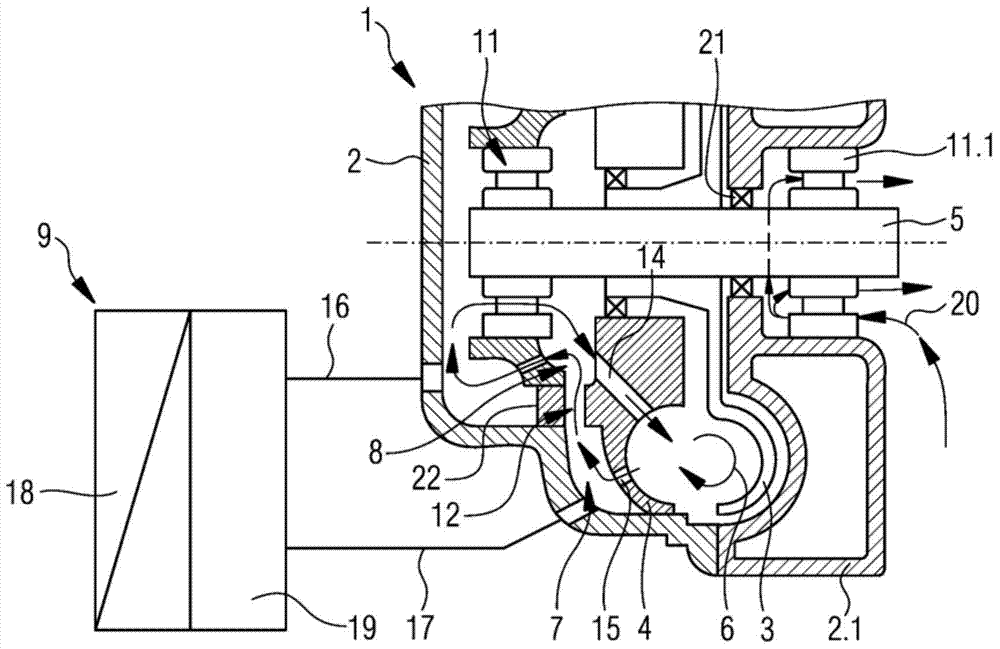

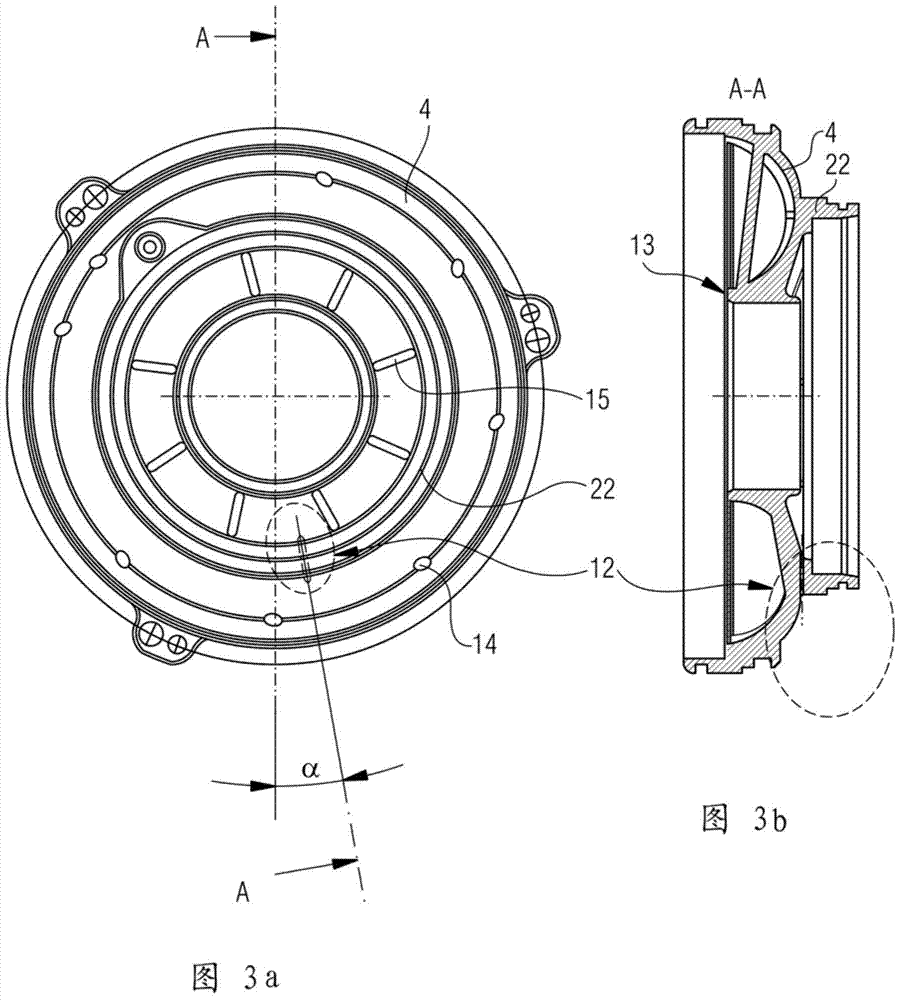

[0025] figure 1 The retarder 1 without connecting channels is shown in braking mode. The working medium is supplied to the inlet region 8 from the external working medium circuit 9 . Oil enters the working space between rotor 3 and stator 4 from inlet region 8 via inlet channel 14 provided here in stator 4 . If the working medium, for example oil, is present in the working space, a braking torque is generated by the retarder, whereby the oil is heated. For cooling purposes, through the pumping action of the retarder, always a partial amount of working medium is pumped back into the external working medium circuit 9 through outlet openings 15 provided here in the stator 4 .

[0026] The external working medium circuit 9 essentially consists of a working medium accumulator 19 to which compressed air can be applied and a cooler 18 . During braking operation, the working medium accumulator 19 is supplied with compressed air, so that working medium enters the retarder 1 or the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com