A gearbox for verifying the axial force of oil pump products

A technology of axial force and gearbox, which is applied in gear lubrication/cooling, belt/chain/gear, pump testing, etc. It can solve the problems that the gearbox cannot be completely sealed, cannot meet the use requirements, and cannot apply axial force, etc. To achieve the effect of no leakage risk, compact structure and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

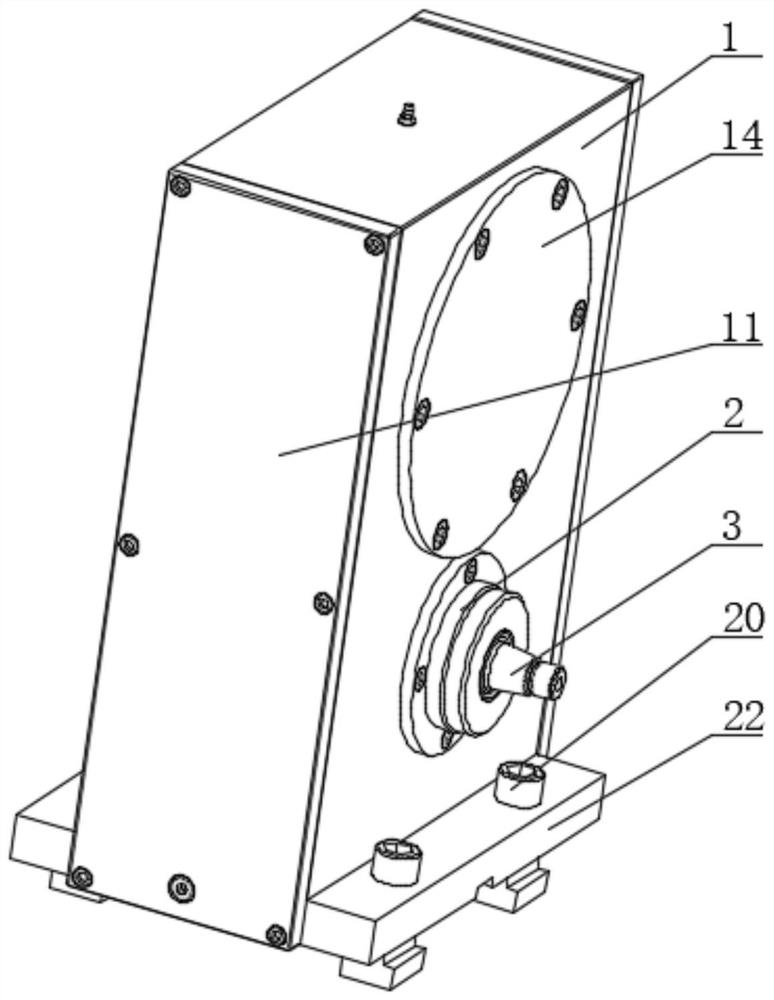

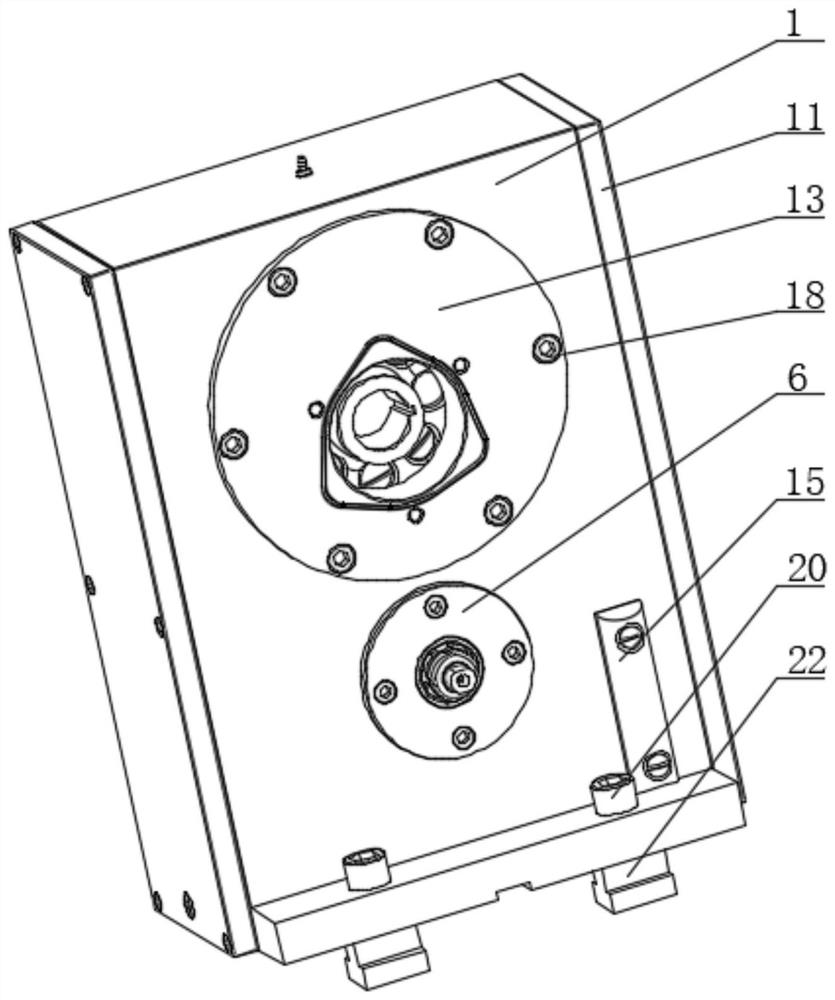

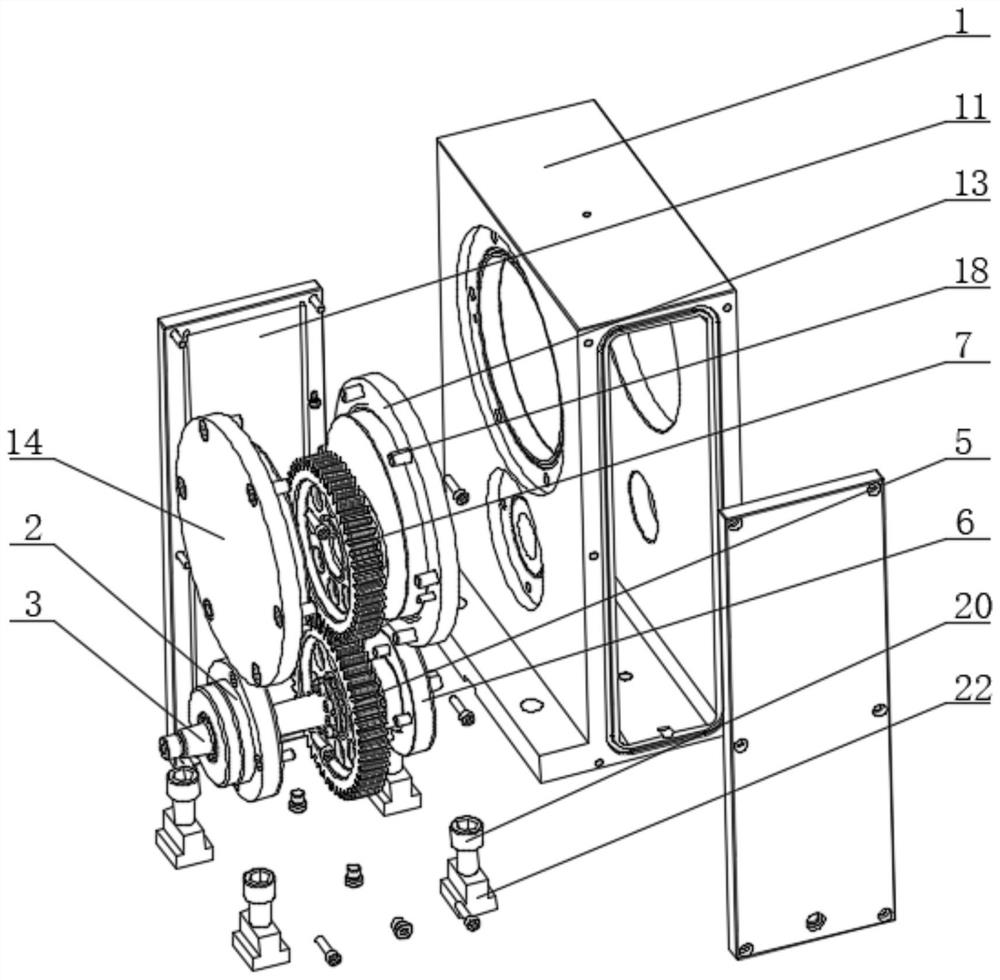

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the gear box for verifying the axial force of oil pump products in this embodiment includes a housing 1, the cross section of the housing 1 is a "back"-shaped structure, and the front and rear ends of the bottom of the housing 1 have folded edges extending outward. A T-block 22 is installed at the flange by a T-block screw 20,

[0034] A drive shaft 3 is installed horizontally below the housing 1, and the front end of the drive shaft 3 is supported by the first oil seal 1201 and the front bearing 4 to install the front cover 2, and the front cover 2 is locked on the housing 1 by the first screw 1901;

[0035] The drive shaft 3 located outside the front cover 2 is connected to the output shaft of the test bench;

[0036] The rear end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com