Digital trusted instrument with CAN interface

A technology of receiver and interface, applied in the field of servo system, can solve the problems of easy interference, too long excitation power supply line, difficult measurement, etc., to reduce the workload of debugging, reduce the workload of calculation, and facilitate the inspection and acceptance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

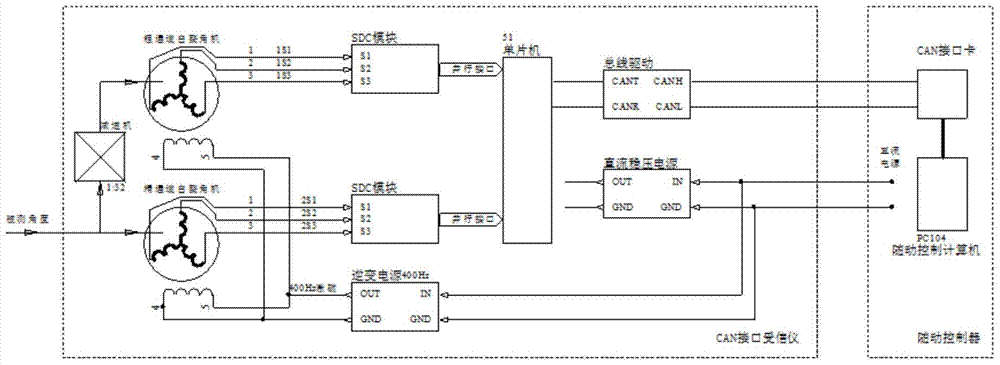

[0059] Embodiment 1 Technical solution: CAN interface receiver using the self-aligning machine solution

[0060] 1) System composition and working principle

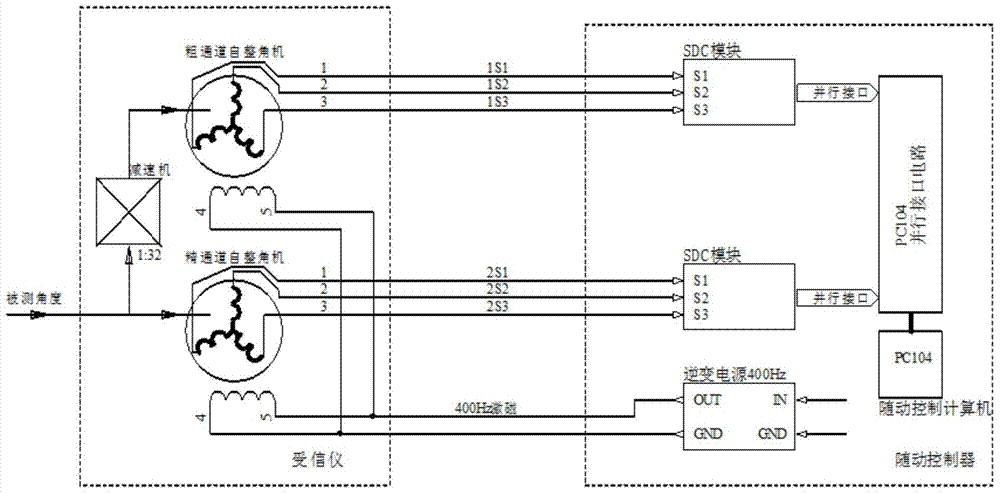

[0061] The system consists of a reducer, two self-aligning machines for coarse and fine channels, and a circuit board for the receiver. The circuit schematic diagram is as follows Figure 7 shown.

[0062] The receiver circuit board consists of: DC to 400Hz115V excitation power supply module, two SDC modules, single-chip microcomputer, CAN driver module, and DC power supply module. Its principle block diagram is as follows: figure 2 shown.

[0063] Its single-chip microcomputer software includes: read the angle digital quantum program of the SDC module, carry out angle digital coarse channel and fine channel angle combination operation subroutine, angle full angle zero position correction operation subroutine, fine channel zero position data correction value receiving, saving and reading Subroutines, subroutines for ...

Embodiment 2

[0066] Embodiment 2 Technical solution: CAN interface receiver using resolver solution

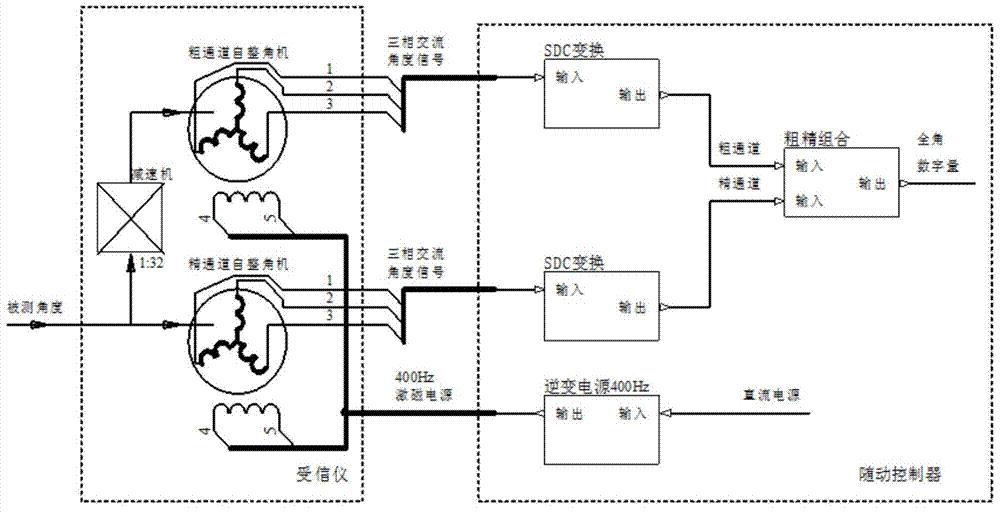

[0067] The system consists of a reducer, two rotary transformers for coarse and fine channels, and a receiver circuit board, such as Figure 8 shown.

[0068] The composition of the receiver circuit board includes: DC to 400Hz115V excitation power module, SDC module, single-chip microcomputer, CAN driver module, DC power module, other schematic diagrams such as Figure 8 shown.

[0069] Its single-chip microcomputer software includes: read the angle digital quantum program of the SDC module, carry out angle digital coarse channel and fine channel angle combination operation subroutine, angle full angle zero position correction operation subroutine, fine channel zero position data correction value receiving, saving and reading Subroutines, subroutines for communicating with the accompanying computer through the CAN interface, subroutines for analyzing and executing commands from the accom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com