tdlas gas temperature measurement and detection device based on optical spectroscopic system

A spectroscopic system and detection device technology, applied in the field of optical detection, can solve the problems of low index, low accuracy and small measurement range of mechanical temperature measurement equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

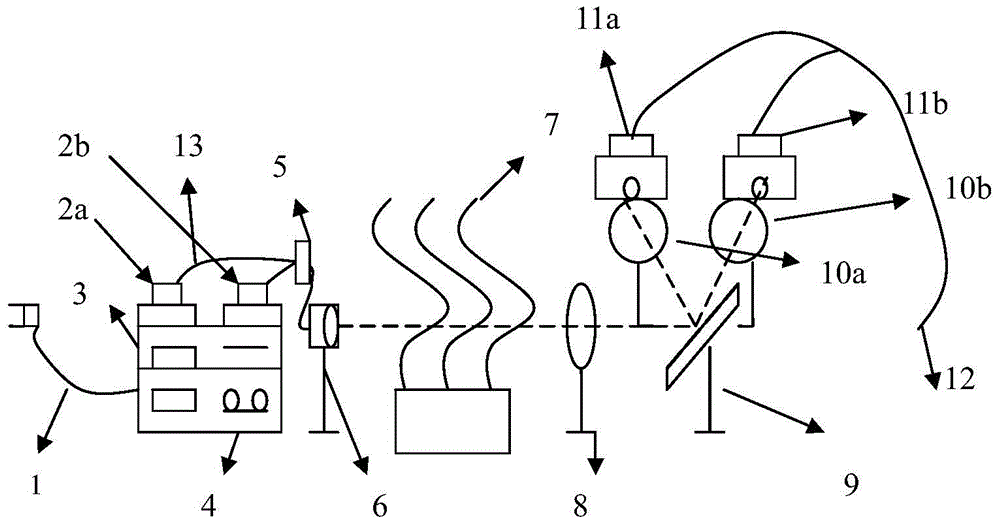

[0060] In this example, if figure 1 As shown, the laser, laser driver, laser signal generator, and laser signal modulator are correctly connected to each other and connected to the power line, the single-mode fiber is connected to the two lasers, and the fiber combiner is connected to the two single-mode fibers. One laser beam is synthesized by one laser beam. The synthesized fiber laser beam is connected with the fiber collimator to emit the beam, and the first plano-convex lens is placed after the flame of the gas to be measured is burned. The center position of the lens is consistent with the center position of the fiber collimator (coaxial) and fixed, and the fiber grating surface is placed At the focal length position of the rear end of the first plano-convex lens, two plano-convex lenses, namely the second plano-convex lens and the third plano-convex lens, are respectively placed on the center of the optical axis of the laser beams with different wavelengths separated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com