Method for measuring speed of vacuum cold-spraying particles

A particle velocity and vacuum cooling technology, which is used in measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., and can solve the problems of low precision and low efficiency of particle velocity measurement in vacuum cold spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

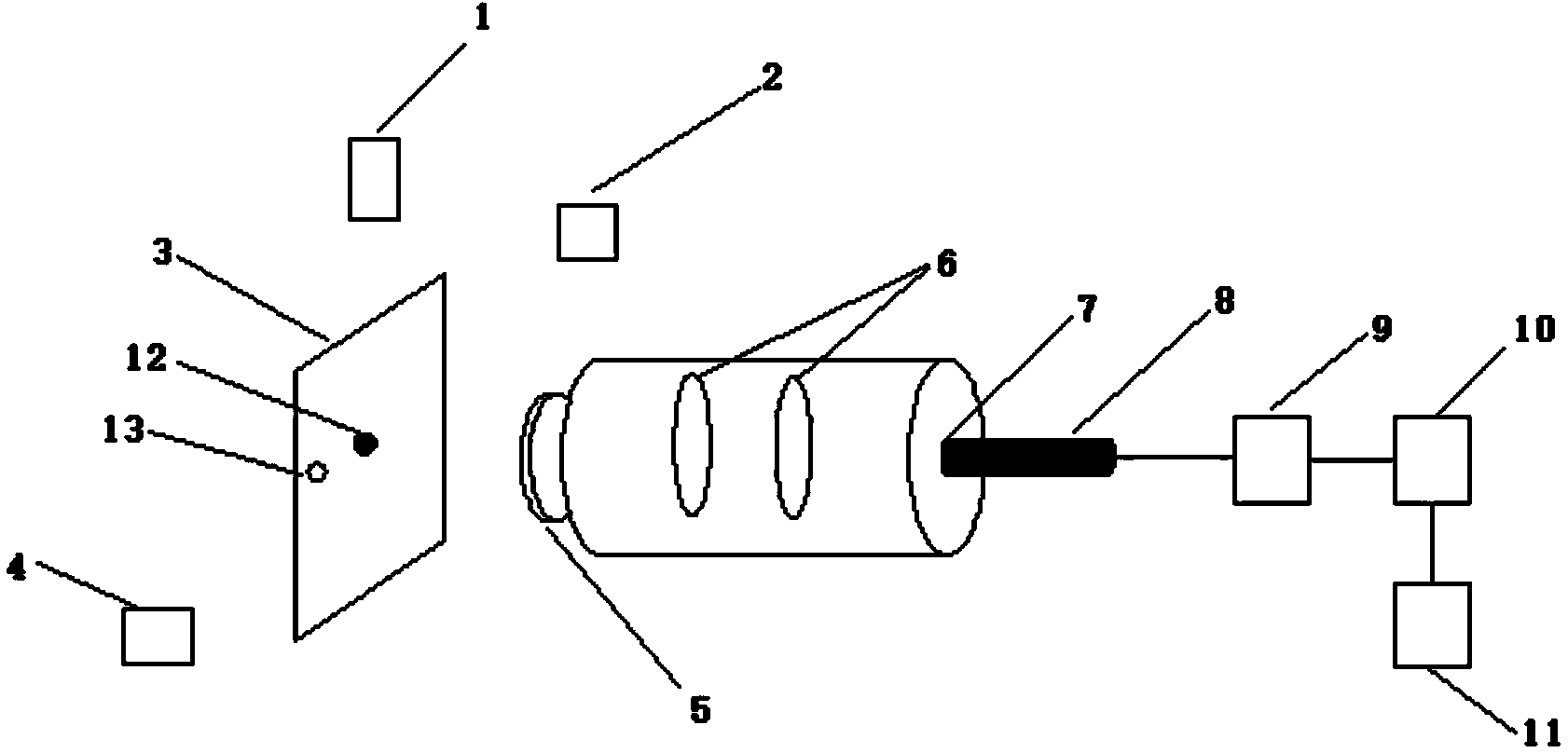

[0062] Such as figure 1 As shown, the structure of the measuring device for vacuum cold spraying particle velocity of the present invention includes a laser emitter 1, a substrate 2, a spraying device 4, an aperture stop 5, a doublet lens group 6, a modulation window stop 7, an optical fiber 8, a photoelectric Converter 9, hardware acquisition card 10, computer 11, wherein, doublet lens group 6 is placed in the inside of aperture diaphragm 5, modulation window diaphragm 7 is connected with optical fiber 8 on the right side of aperture diaphragm 5, modulates window light Diaphragm 7 forms a modulation window diaphragm ideal image plane 3 behind the doublet lens group 6, the modulation window diaphragm ideal image plane 3 is on the focal plane of the doublet lens group, and the laser transmitter 1 is on the modulation window diaphragm ideal ima...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap