Industrial field equipment remote diagnosis maintenance system and method

A technology for industrial field equipment and remote diagnosis, applied in general control systems, control/regulation systems, test/monitoring control systems, etc. The effect of time, rich functions, and low implementation cost for on-site equipment troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

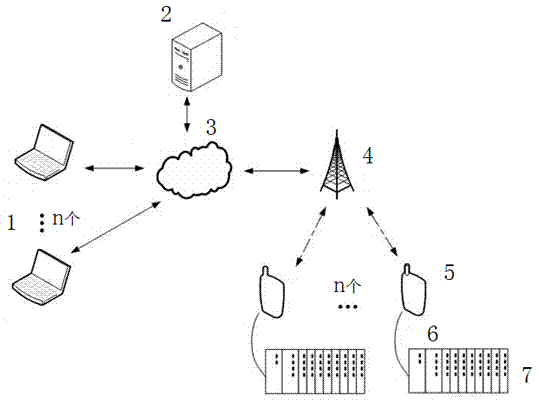

[0025] Such as figure 1 As shown, a remote diagnosis and maintenance system for industrial field equipment includes an engineer station 1 , a remote bridge server 2 , the Internet 3 , a wireless network 4 , a universal mobile terminal 5 , a USB cable 6 and a field device 7 . The engineer station is connected to the remote bridging server through the Internet, the remote bridging server is connected to the general mobile terminal through the wireless network, and the general mobile terminal is connected to the field equipment through a USB cable.

[0026] There can be a group of n engineering stations; there can also be a group of n field devices, and the general mobile terminal and USB cable match the number of field devices. Among them, the engineer station sends remote diagnosis and maintenance requests and processes diagnosis and maintenance data, the remote bridge server establishes the communication connection service between the engineer station and the general mobile te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com