Parallel-welded printed circuit board connector

A printed circuit board and parallel soldering technology, which is applied in the direction of connection, circuit, fixed connection, etc., can solve problems such as many contact points, solder balls cannot be in contact with printed circuit boards, and terminals and solder joints are soldered. The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

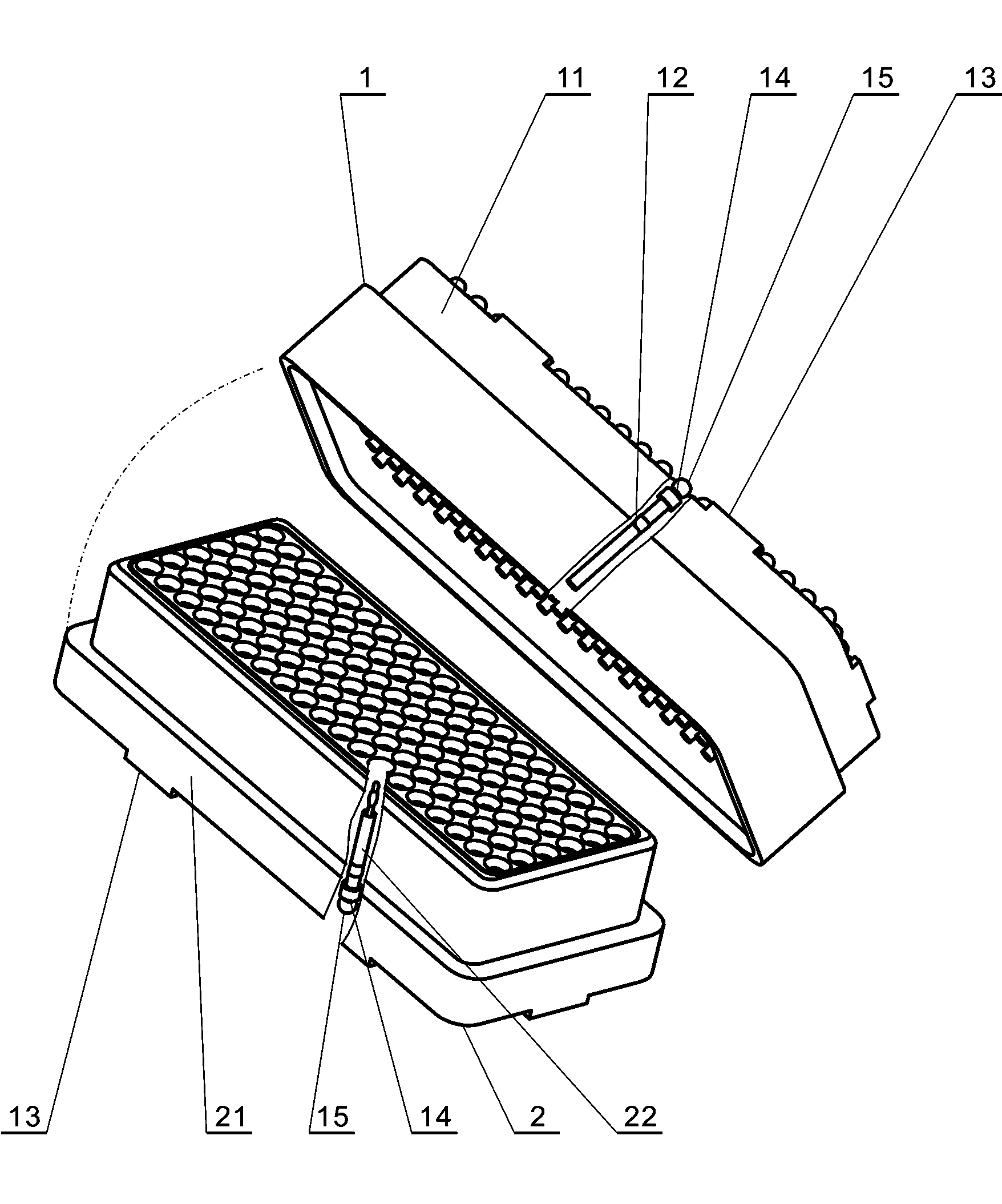

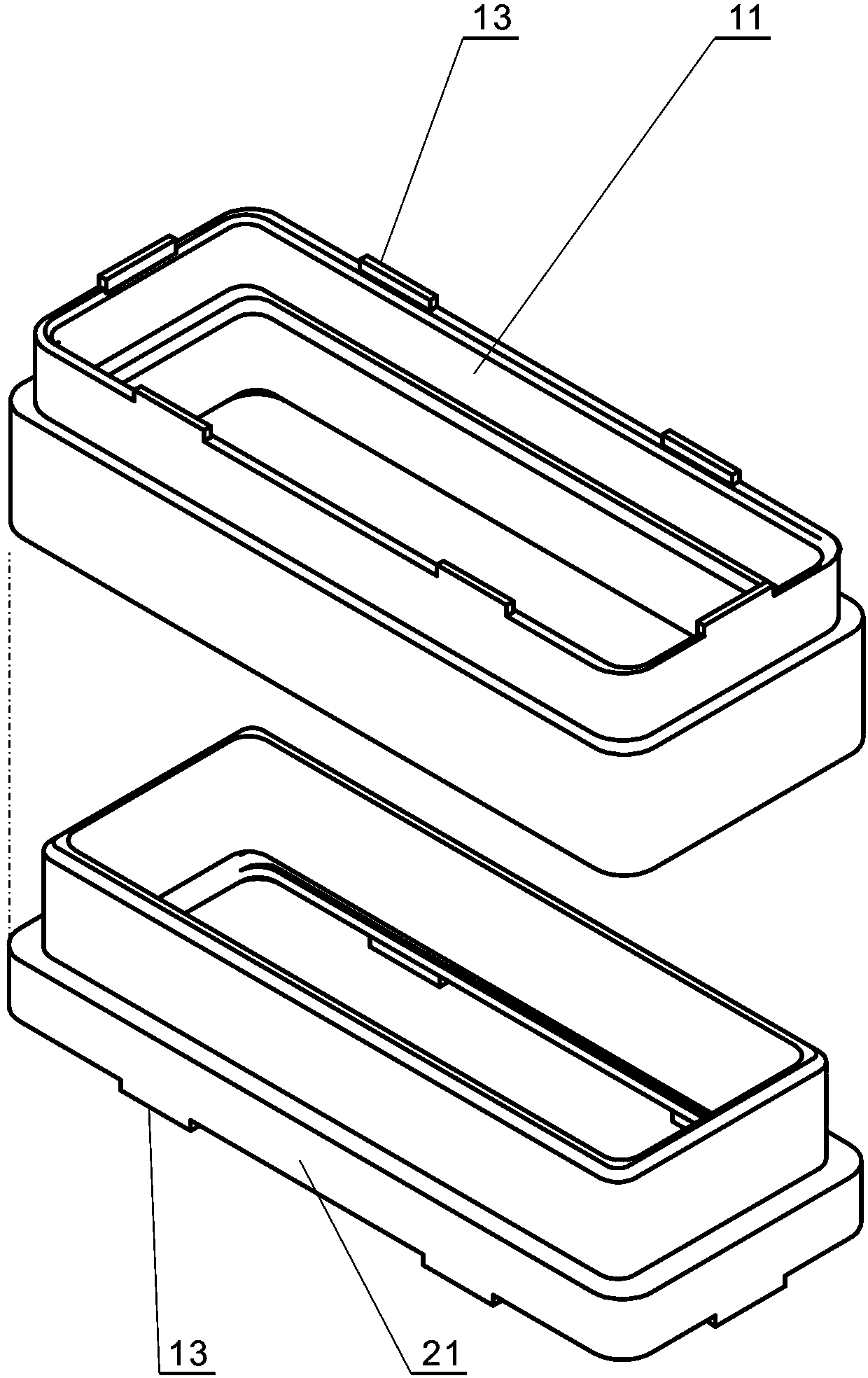

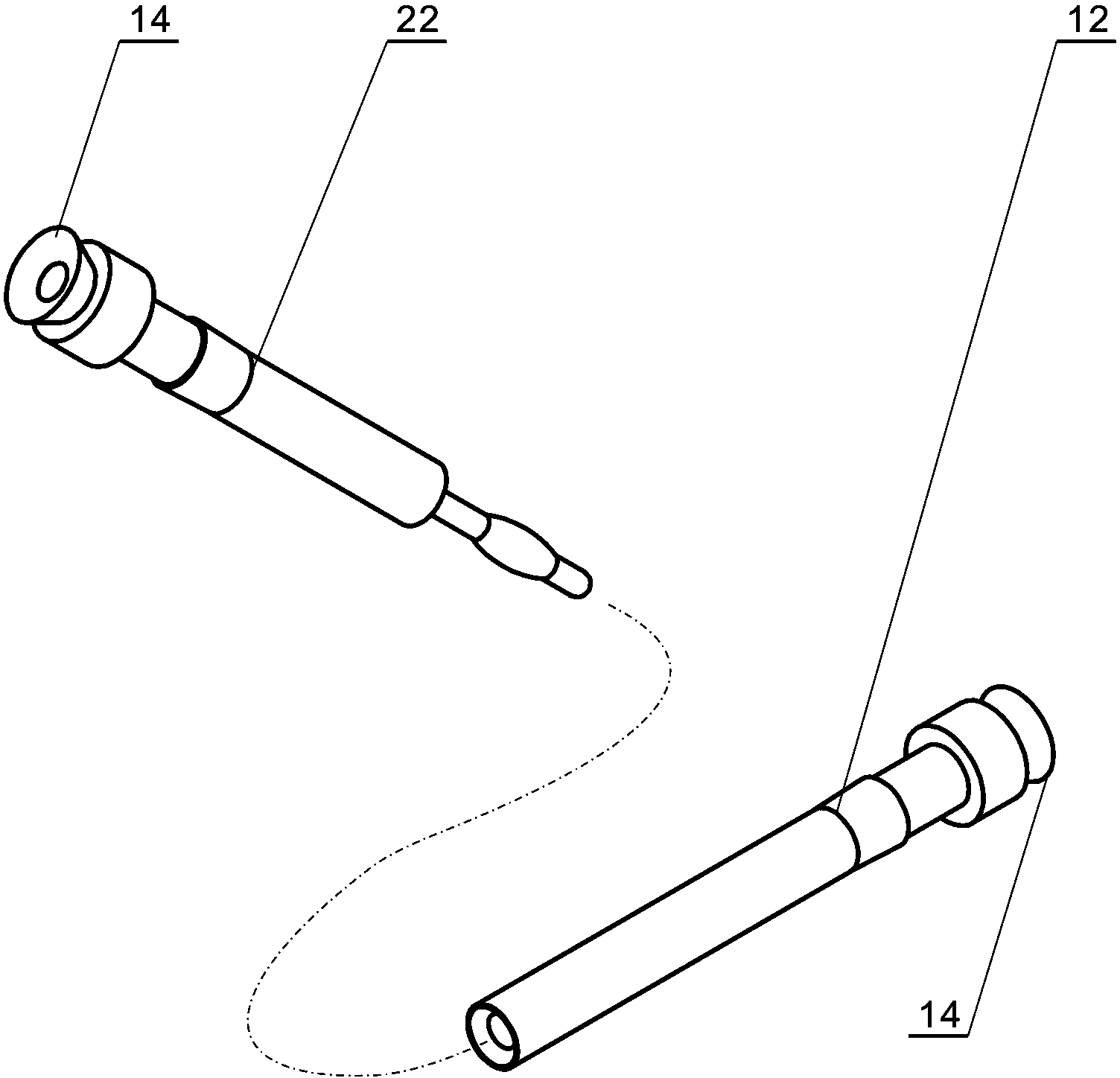

[0013] refer to figure 1 , figure 2 , image 3 , the present invention includes a plug 1 and a socket 2, the plug 1 is composed of a plug shell 11 and a jack fitting 12, the socket 2 is composed of a socket shell 21 and a pin fitting 22, and both the plug shell 11 and the socket shell 21 are provided with There are several terminal receiving grooves; the present invention is that the plug shell 11 and the socket shell 21 are both rectangular shells, and one end surface is provided with several support bosses 13 of equal height, and the socket fitting 12 and the pin fitting 22 are both columnar, one end of which is provided with a concave bell mouth 14, and a solder ball 15 is arranged in the bell mouth 14;

[0014] The socket assembly 12 and the pin assembly 22 are respectively arranged in the receiving grooves of the plug housing 11 and the socket housing 21, and one end of the socket assembly 12 and the pin assembly 22 provided with the solder ball 15 faces the plug. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com