milling machine

一种碾谷机、碾谷的技术,应用在碾谷机领域,能够解决碾米行程长行程化、电费增大、花费时间等问题,达到实现短流程化、削减电费、结构简易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

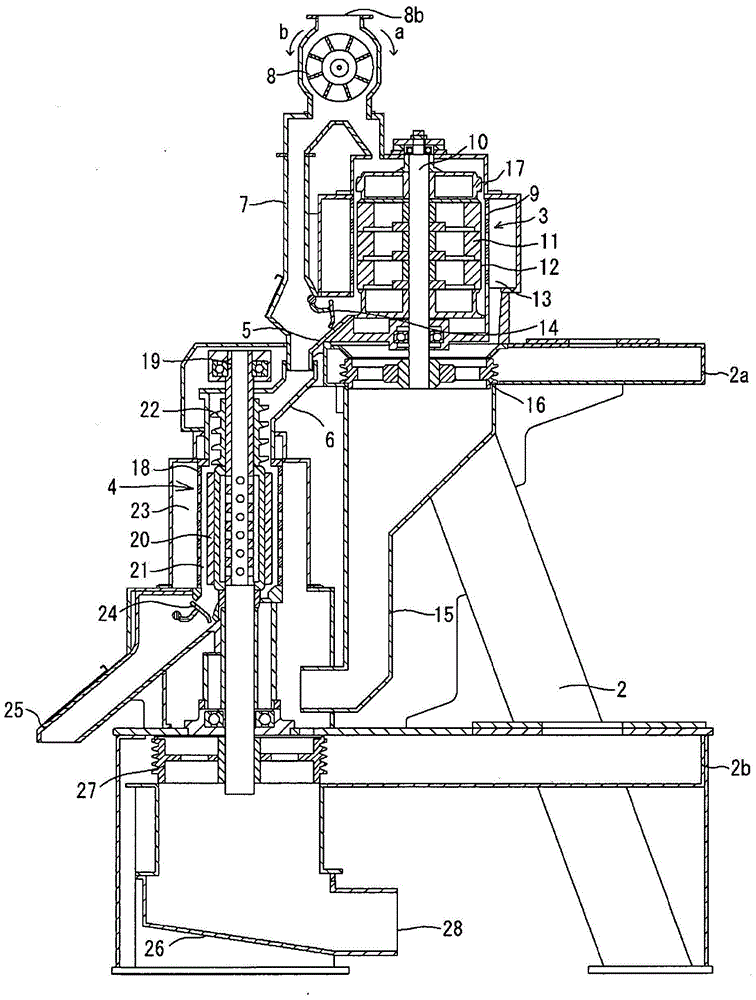

[0021] While referring to the attached Figure 1 Embodiments for carrying out the present invention will be described. figure 1 It is a perspective view showing the whole of the rice milling machine of the present invention, figure 2 It is a schematic longitudinal sectional view showing the internal structure of the color sorter of the present invention.

[0022] The rice milling machine 1 of the present invention can perform milling of grains such as rice and wheat, grinding of resin particles, grinding of coffee beans, and grinding of the surface thereof with other granular materials as raw materials.

[0023] Such as figure 1 As shown, the rice milling machine 1 of the present invention is formed on the upper part 2a of the multi-stage base frame 2 to configure the down-feed grinding type rice milling part 3, and on the lower part 2b of the base frame 2 to configure the down-feed Type of friction milling section 4. And, if figure 2 As shown, the fine product discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com