Rotary type bi-directional buffer device of aircraft docking mechanism

A technology of docking mechanism and two-way buffering, which is applied to the docking device of aerospace vehicle, low internal friction spring, etc., can solve the problem that the two-way transmission buffer device cannot adapt to the occasion of large-angle buffering stroke, etc., and achieves simple structure and smooth torque-angle characteristic curve. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

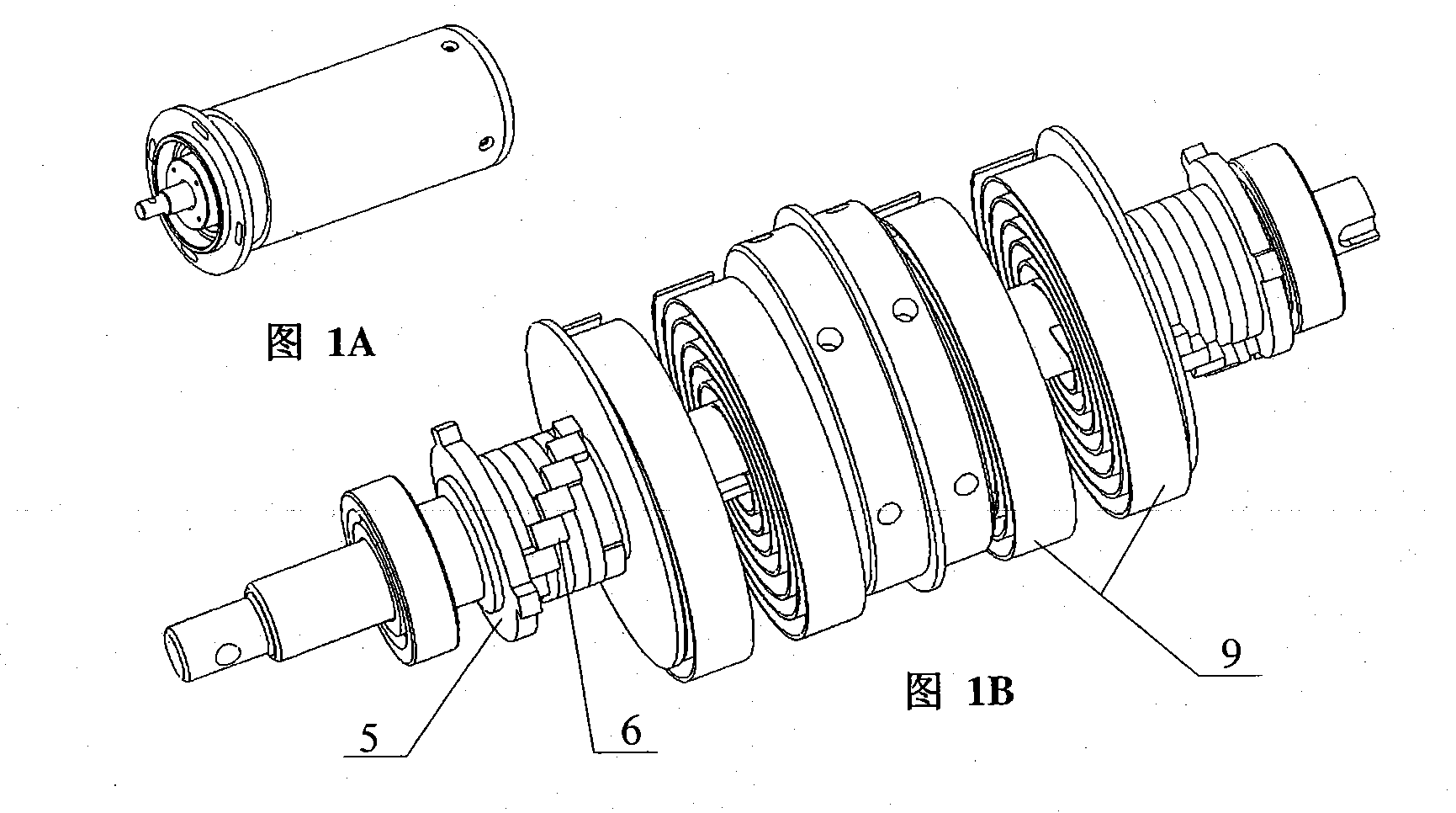

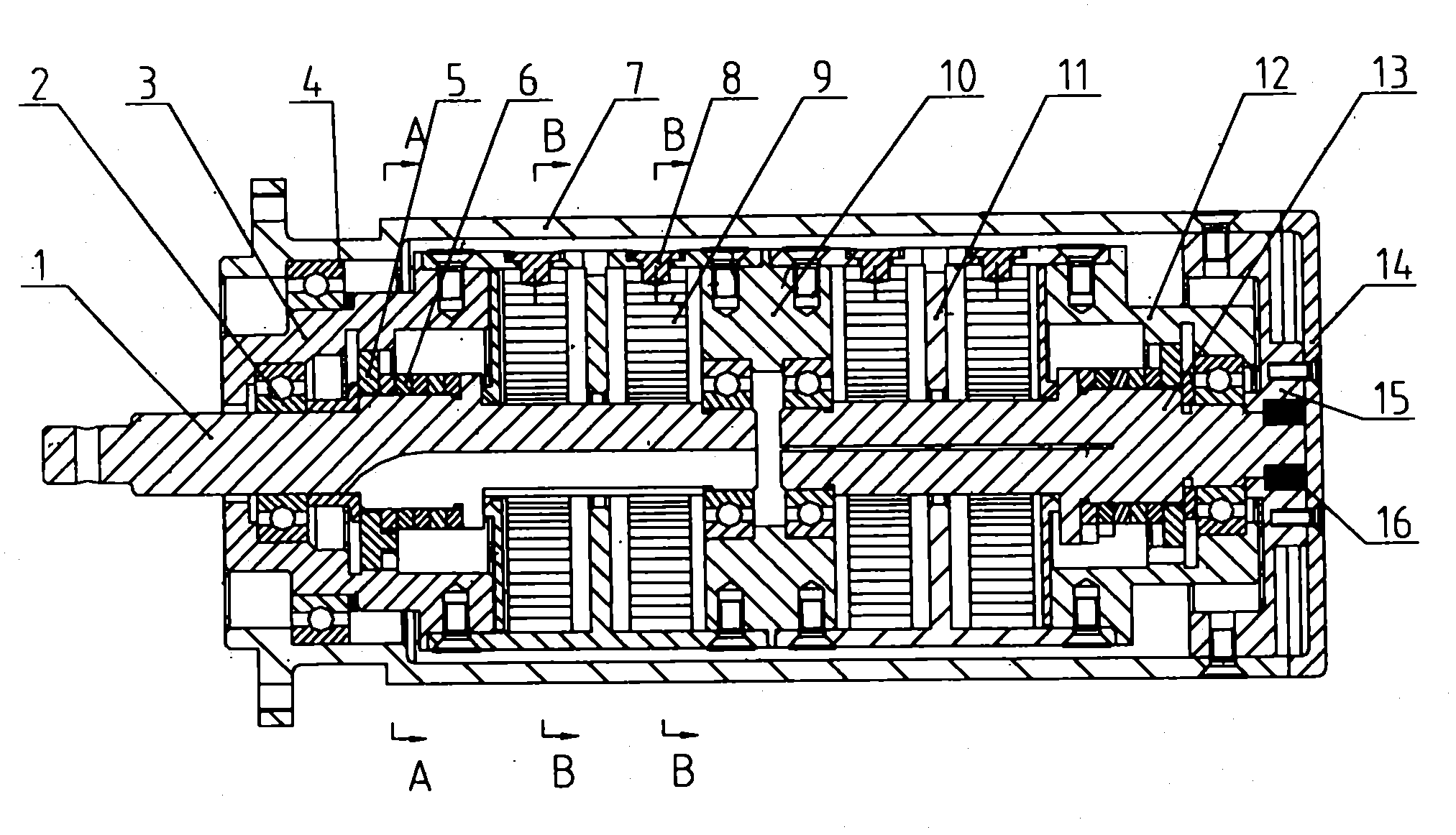

[0030] Figure 1~4 It is an embodiment of the single-rotation rotary two-way buffer device of the aircraft docking mechanism of the present invention. This mechanism can realize the collision buffer between the XX aircraft and the YY aircraft, reduce the peak load during the collision and impact, and realize the recovery correction.

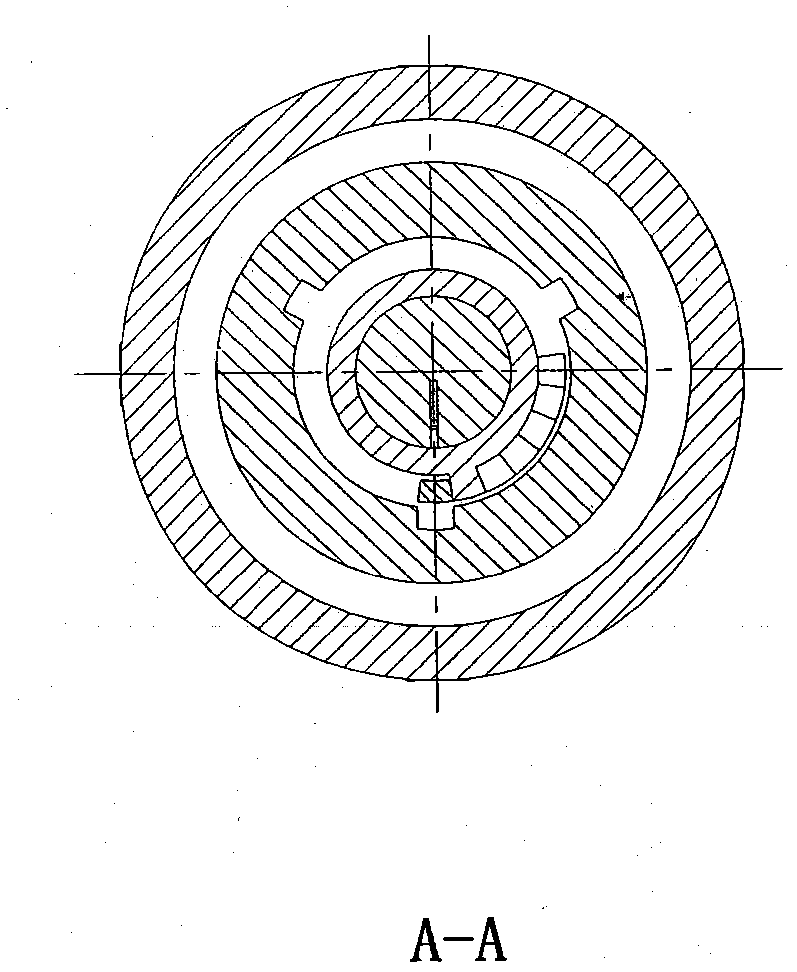

[0031] figure 1 A is the outline drawing of the single-shaft rotary two-way buffer device; figure 1 B is the exploded view of the device after removing the shell; figure 2 Is a sectional view; image 3 Is along figure 2 A cross-sectional view taken on line A-A in; Figure 4 Is along figure 2 Sectional view taken on line B-B in.

[0032] Such as Figure 1~4 As shown in the embodiment, the device includes: rotating shaft 1, A bearing 2, front sleeve 3, B bearing 4, cam disk I5, cam disk II6, immovable housing 7, bayonet 8, planar scroll spring 9, The coupling body 10, the movable housing 11, the rear sleeve 12, the shaft 13, the housing 14, the baffl...

Embodiment 2

[0039] Figure 5-9 It is an embodiment of the dual-rotation-axis rotating bidirectional buffer device of the aircraft docking mechanism of the present invention. The device can realize differential buffering between the two shafts in the XX aircraft docking buffer mechanism.

[0040] Figure 5 A shows the internal structure of Example 2; Figure 5 B shows its appearance. Image 6 Is a sectional view; Figure 7 Is along Image 6 A cross-sectional view taken on line A-A in; Figure 8 Is along Image 6 Sectional view taken on line B-B in; Picture 9 Is along Image 6 A cross-sectional view taken along the line C-C.

[0041] Such as Figure 5-9 As shown in the embodiment, the device includes: a rotating shaft 21, a C bearing 22, a cam sleeve 23, a housing 24, a spacer 25, a bayonet 26, a planar scroll spring 27, and a cam disc 28.

[0042] Such as Figure 5 As shown in A, the flat scroll spring 27 is divided into left and right parts, and they are installed in the same direction. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com