Method and equipment for storing and pre-treating kitchen wastes

A food waste and pretreatment technology, which is applied in the field of solid-liquid separation and short-term storage of food waste, can solve the problems of environmental pollution, low energy consumption, and large energy consumption, and achieve low energy consumption, Effect of reducing adverse effects and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

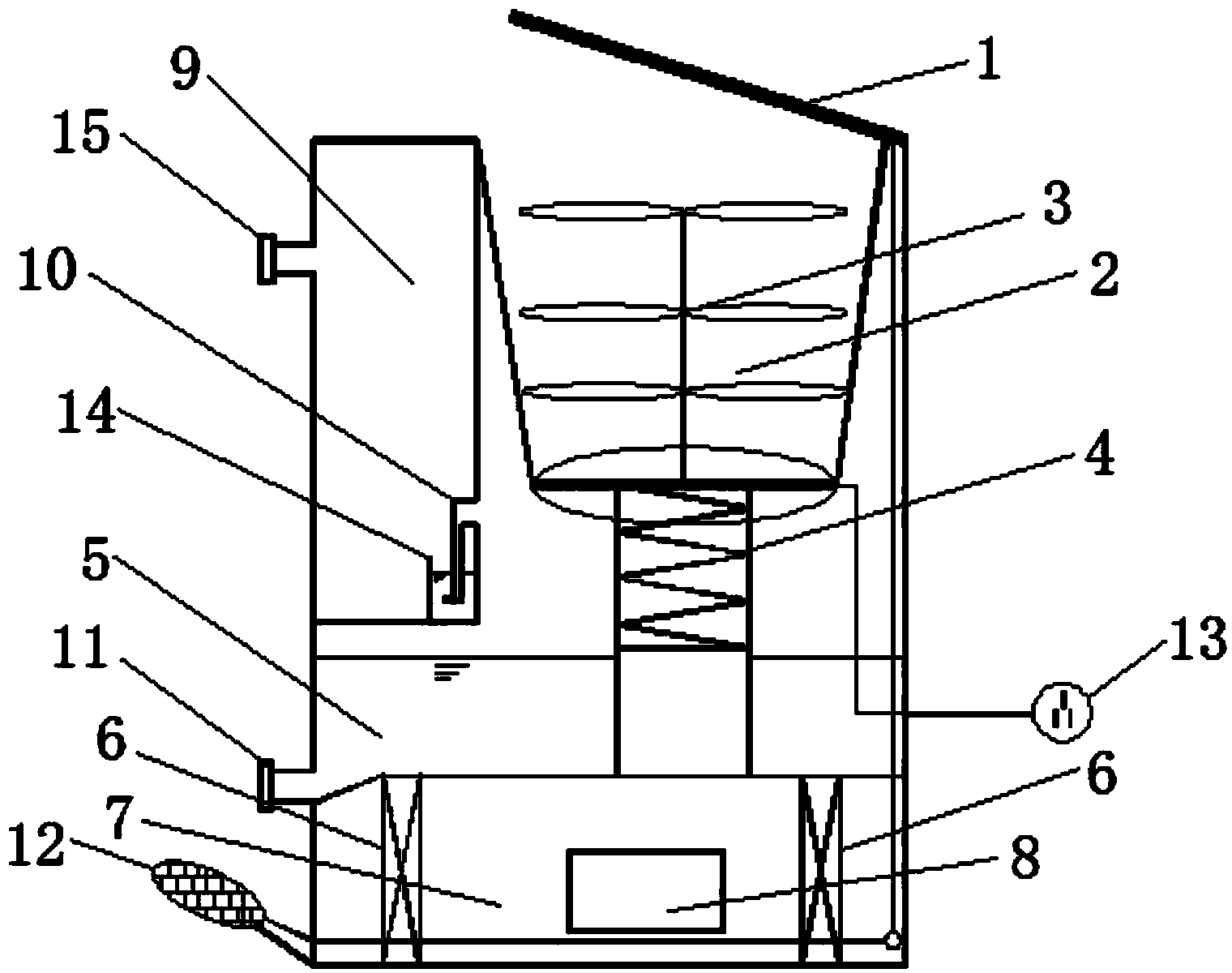

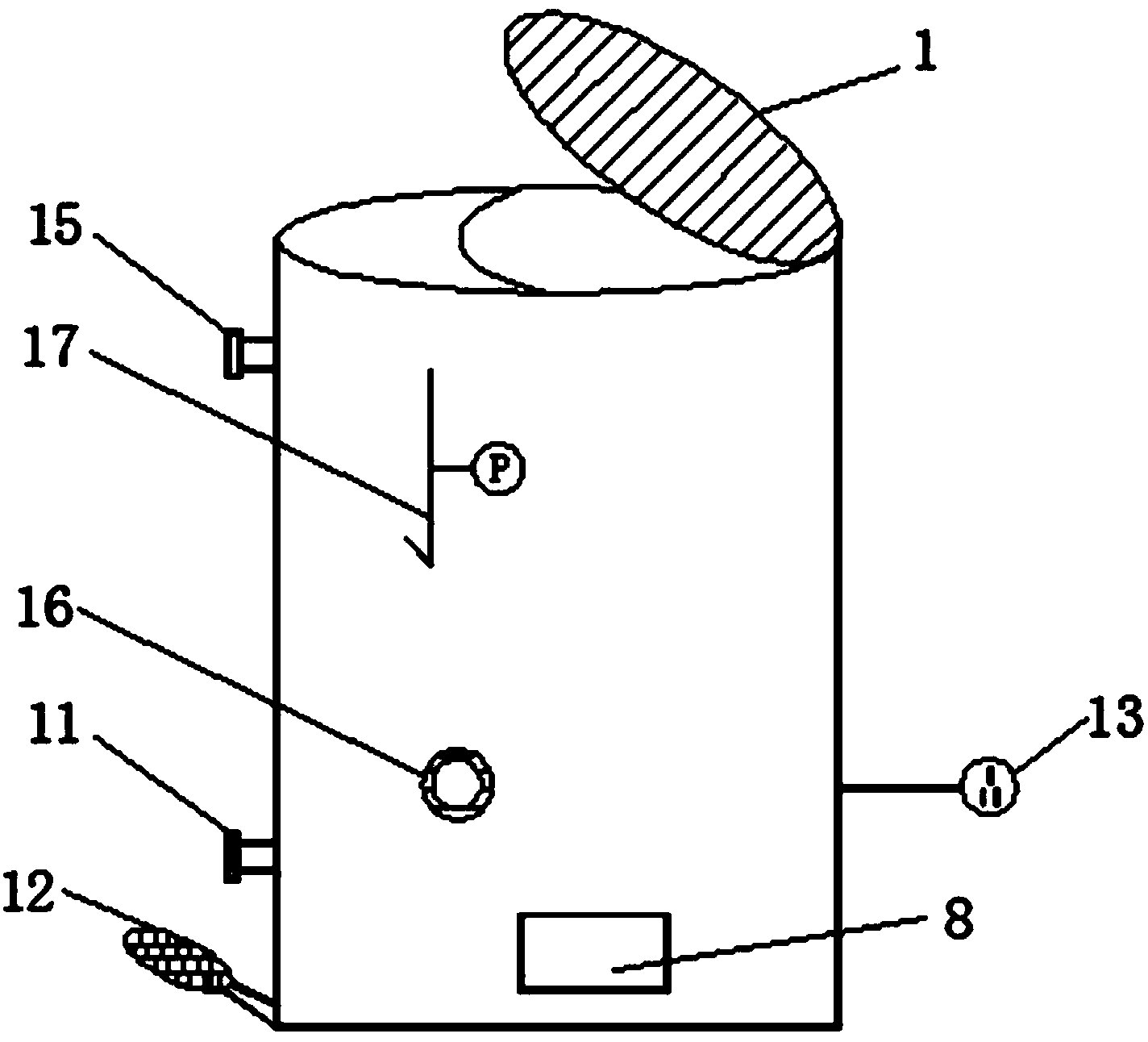

[0019] Such as Figures 1 to 2 As shown, a food waste storage and pretreatment equipment, the equipment includes a housing, the housing is provided with a pretreatment unit 2, a compression unit 4, a liquid storage unit 5, a solid storage unit 7 and a gas storage unit 9; wherein , the pretreatment unit 2 is located on the upper part of the housing, and is used for the crushing of food waste; the compression unit 4 is located at the bottom of the pretreatment unit 2, and is connected to the bottom of the pretreatment unit 2, and is used for compressing the broken food waste. Garbage, realize the solid-liquid separation of kitchen waste; the liquid storage unit 5 is located at the bottom of the compression unit 4, and carries the compression unit 4 and the pretreatment unit 2, and is used to store the liquid generated by the pretreatment unit 2 and the compression unit 4; solid storage The unit 7 is arranged at the bottom of the casing, and its top is connected with the compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com