Die for lateral hole flanging of upper cross plate of automobile seat backrest

A technology for car seats and backrests, which is applied in the field of molds for the sideways turning holes of the car seat backrests. It can solve the problems of low product quality, poor stability, and long strokes, and achieve high pass rate and ingenious structure. , reduce the effect of the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

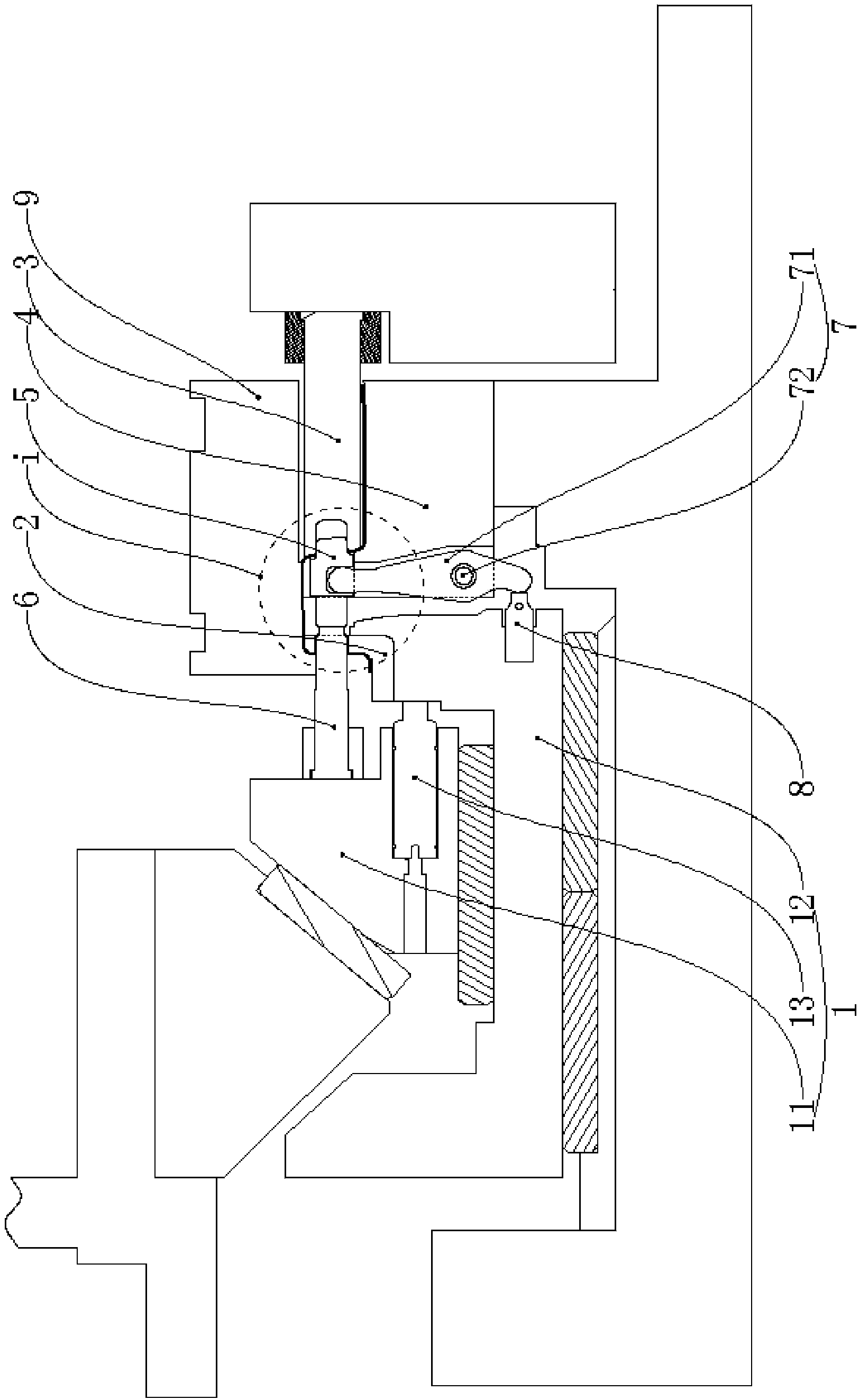

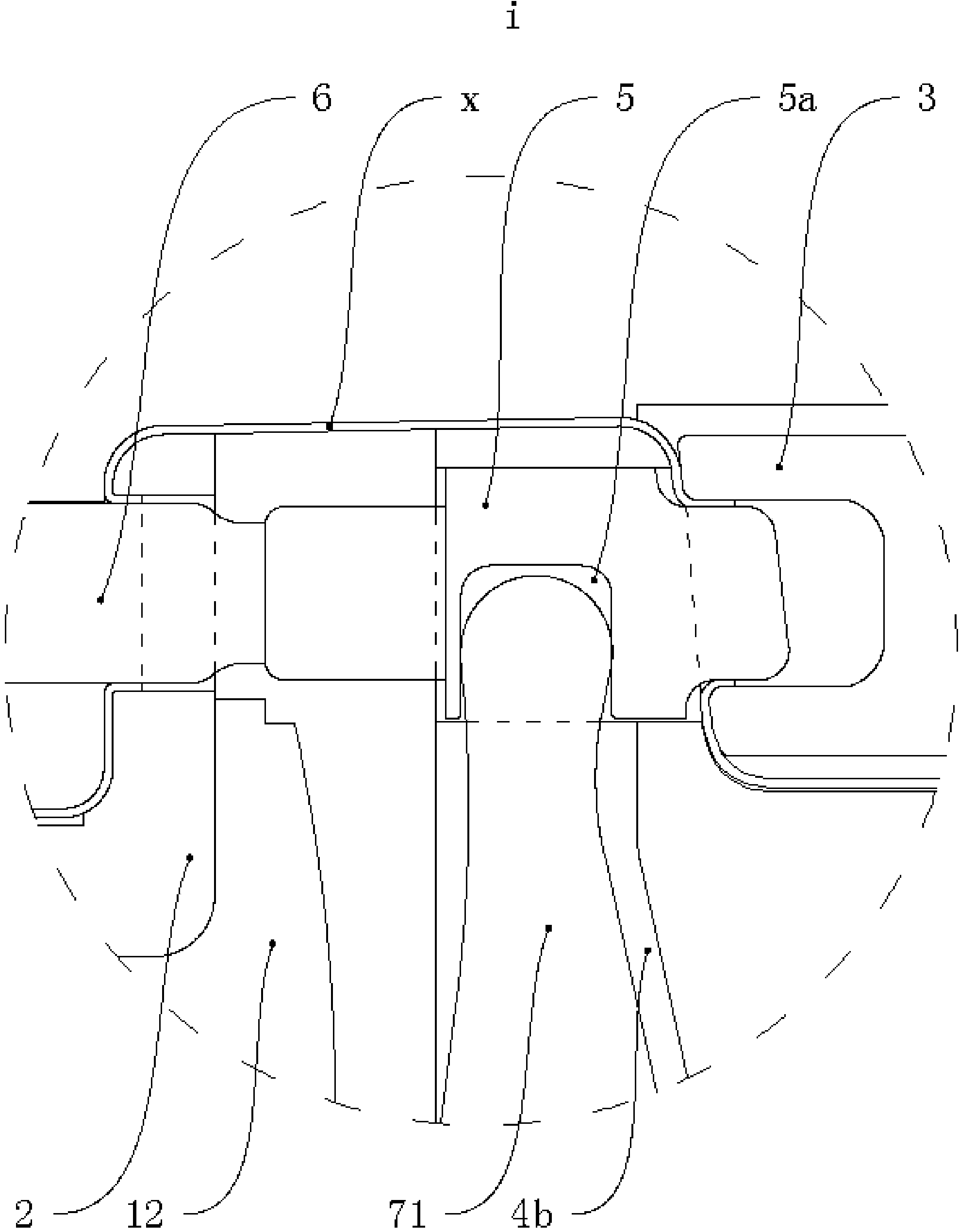

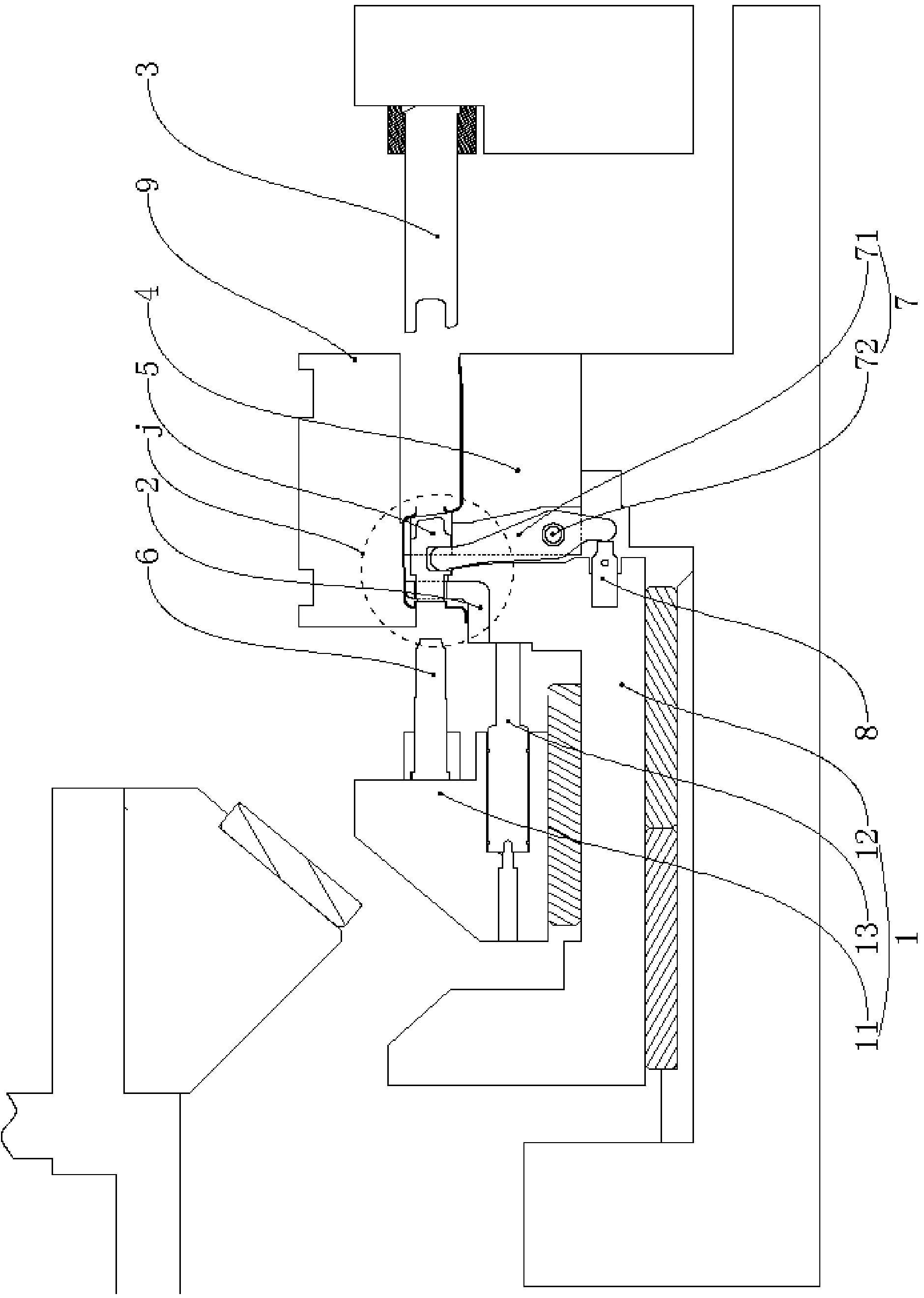

[0027] Such as Figure 1 to Figure 4 Shown, a kind of mold that is used for the rollover hole of the horizontal plate on the backrest of an automobile seat comprises a lower mold base 1 arranged on a worktable, a first punch 6 is arranged on the lower mold base 1, and a first punch 6 is arranged on the lower mold base 1. A first die 2 and a second die 3 are correspondingly arranged on the said workbench on the same side of a punch 6 in turn, and the die cavity of the first die 2 and the die cavity of the second die 3 are all consistent with the die cavity of the second die 3. The first punch 6 is arranged oppositely, and the lower die core 4 is arranged between the first die 2 and the second die 3; figure 2 and Figure 4 It can be seen that a punch guide through hole 4a is opened on the upper part of the lower mold core 4, and a second punch 5 is pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com