Special cutting machine of convex tooth on hollow cylinder

A hollow cylinder, cutting machine technology, applied in welding/cutting auxiliary equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of poor workpiece accuracy and high work intensity of operators, and achieves reduced labor intensity and accurate tangent point. The effect of convenient location and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

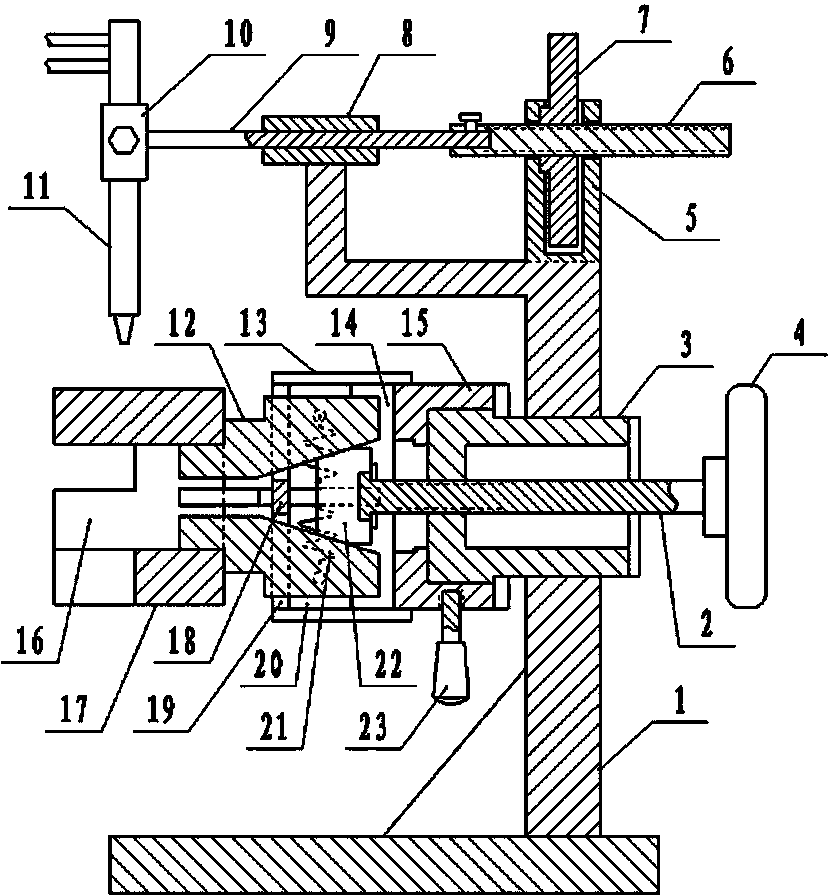

[0009] Embodiment one: if figure 1 , figure 2 and image 3 As shown, a special cutting machine for convex teeth on a hollow cylinder is designed with a fork frame 5 with a hole in the middle on the upper end of the bracket 1, and a horizontal fixing sleeve 8 with a square groove in the middle is installed on one side of the upper end of the bracket 1. The cross-section of the blanching gun fixing rod 9 is square, the front end is equipped with a vertical fixing sleeve 10, the middle part is set in the horizontal fixing sleeve 8, the rear end is inserted in the front end of the translation screw rod 6, and the welding torch 11 is installed in the vertical fixing sleeve 10. The translation turntable 7 is installed in the middle part of the fork frame 5, and the translation screw rod 6 passes through the opening of the fork frame 5 and the screw hole of the welding torch translation turntable 7; The fixed sleeve 3 at the end is installed in the middle of the bracket 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com