Operation-convenient blowing mold

A blow mold, easy-to-operate technology, applied in the field of blow mold, can solve the problems of not suitable for small enterprises, high investment cost, complicated structure, etc., and achieve the effect of simple structure, convenient use and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

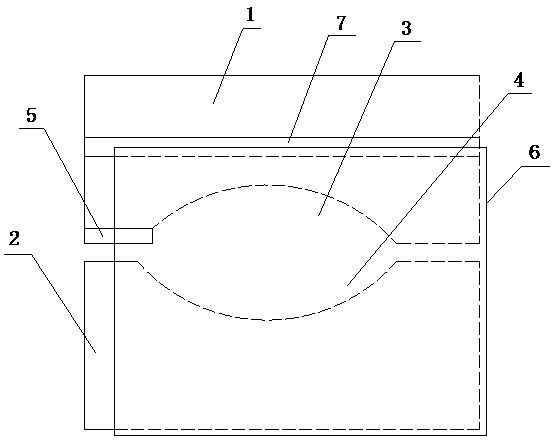

[0012] like figure 1 As shown, a kind of easy-to-operate blow molding mold of the present invention comprises a mold body, and the mold body includes a first half 1 and a second half 2, a first cavity 3 is opened in the middle of the first half 1, and a second half There is a second mold cavity 4 in the middle of the half 2, a first runner 5 is opened on one side of the first mold cavity 3, chute 7 is provided at both ends of the first half 1, the first half 1 and the second half 2 The outside is provided with a fixed clip 6, which cooperates with the chute 7. The shape of the fixed clip 6 is L-shaped, and the first half 1 and the second half 2 are closed to complete the pressing of the article.

[0013] The invention has the advantages of simple structure, convenient use, fixed by a fixing clamp, and good stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com