Antistatic fabric with fabric with pattern

An anti-static and anti-static layer technology, applied in the field of textile fabrics, can solve the problems of mechanical properties such as large differences in ductility and tensile strength, fabrics without patterns, and discomfort, so as to improve comprehensive performance and enhance safety , Good anti-static performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

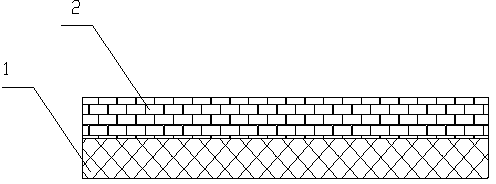

[0014] see figure 1 , the present invention relates to an antistatic fabric with a pattern, comprising a base layer 1, the surface of the base layer 1 is provided with an antistatic layer 2, and the antistatic layer 2 is woven by warp yarns and weft yarns, and the warp yarns It is made of cotton yarn, the weft yarn is made of conductive fibers, and the conductive fibers are striped with a spacing of 5-10mm.

[0015] In a preferred embodiment of the present invention, an antistatic agent is added to the antistatic layer 2 . It can eliminate all kinds of static electricity accumulation and bacteria caused by friction on the fabric, and prevent static electricity interference and dust adhesion.

[0016] The base layer is made of fabric, and the fabric is interwoven with warp and weft yarns. Its organizational structure is a 3 / 1 interwoven twill weave structure. The density is 25 threads / cm, the weft density is 16 threads / cm, and the warp yarn adds Z twist 180 threads / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com