Vacuum transportation lifting device with reversing function

A lifting device and transportation device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of item damage, limited conveying height manipulator, etc., and achieve the effect of not being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

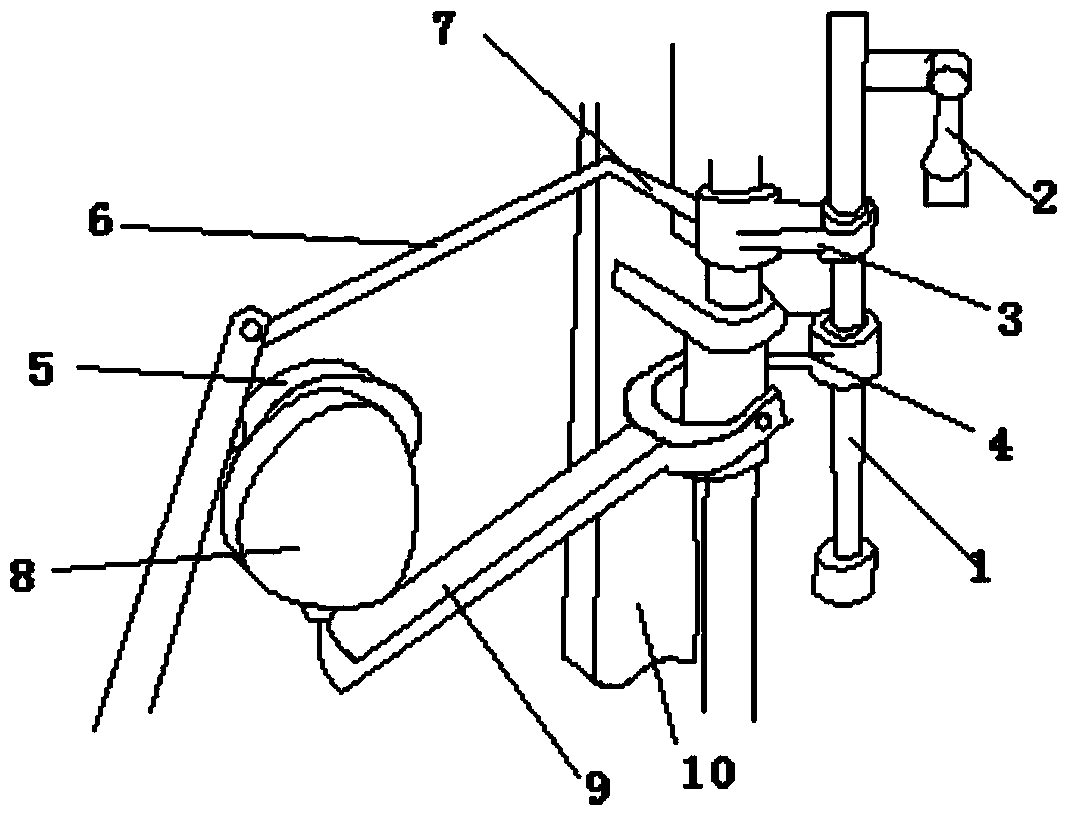

[0013] The reference signs in the description of the drawings are: transmission shaft 1, vacuum suction head 2, transposition arm 3, lifting arm 4, reversing cam 5, push rod 6, rotating arm 7, lifting cam 8, toggle lever 9, Rack10.

[0014] Such as figure 1 As shown, the technical solution provides a vacuum transport lifting device with reversing, including a frame 10, a transport device, a reversing device and a lifting device, the frame 10 is vertically provided with a fixed shaft, and the transport device includes Drive shaft 1, vacuum suction head 2, transposition arm 3 and lifting arm 4, vacuum suction head 2 is " L " shape and is vertically installed on the upper end of transmission shaft 1 downwards. One end of the transposition arm 3 is fixed above the transmission shaft 1, and the other end is fixedly connected with a sleeve, and is sleeved on the fixed shaft through the sleeve. One end of the lifting arm 4 is fixed on the transmission shaft 1 below the transpositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com