Elbow for various pipelines

A technology of pipe elbows and types, applied in the directions of elbows, pipes/pipe joints/fittings, pipes, etc., can solve the problems of difficult entry and exit, cable jamming, cumbersome construction process, etc., to reduce the bending arc and prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings:

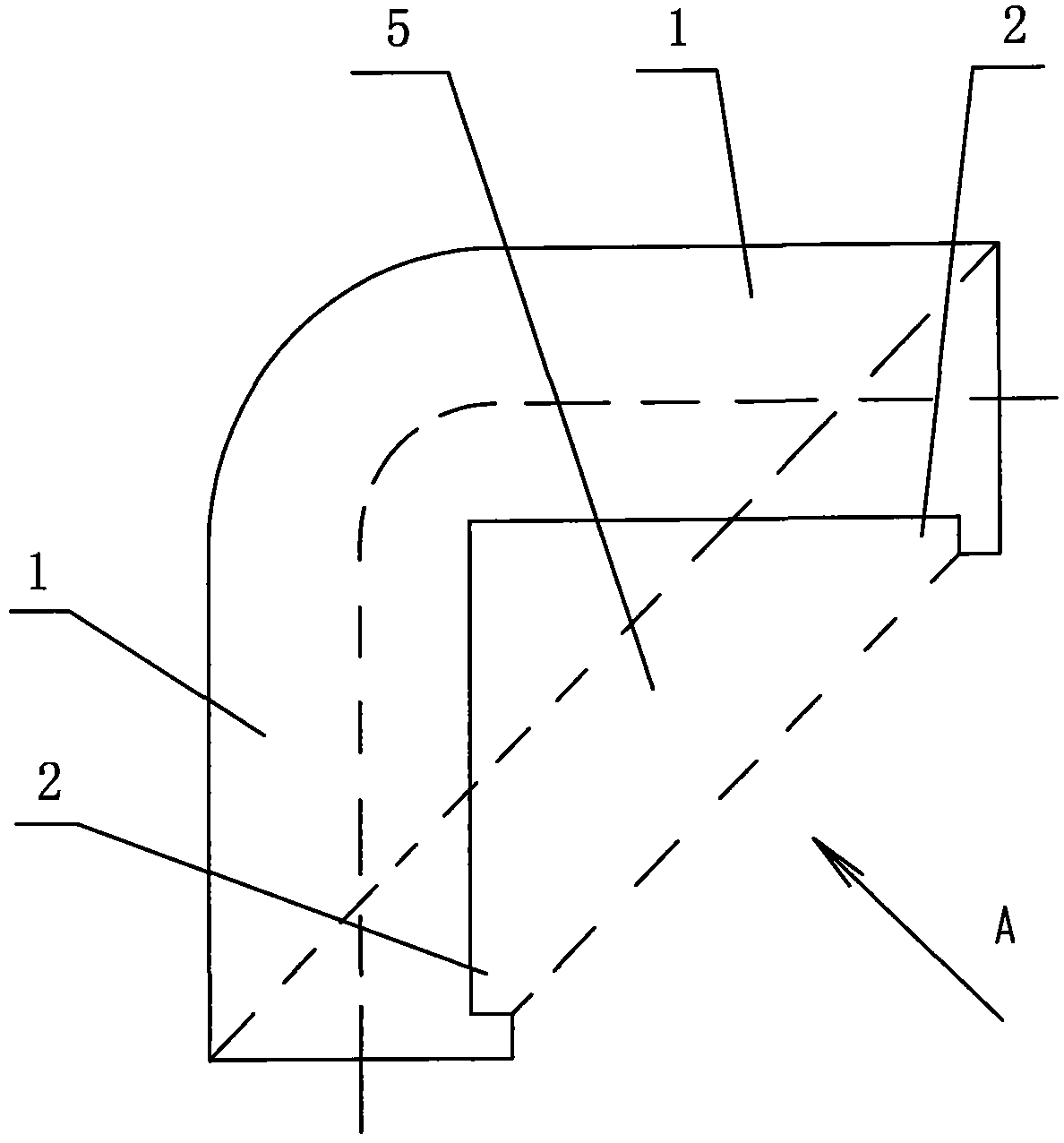

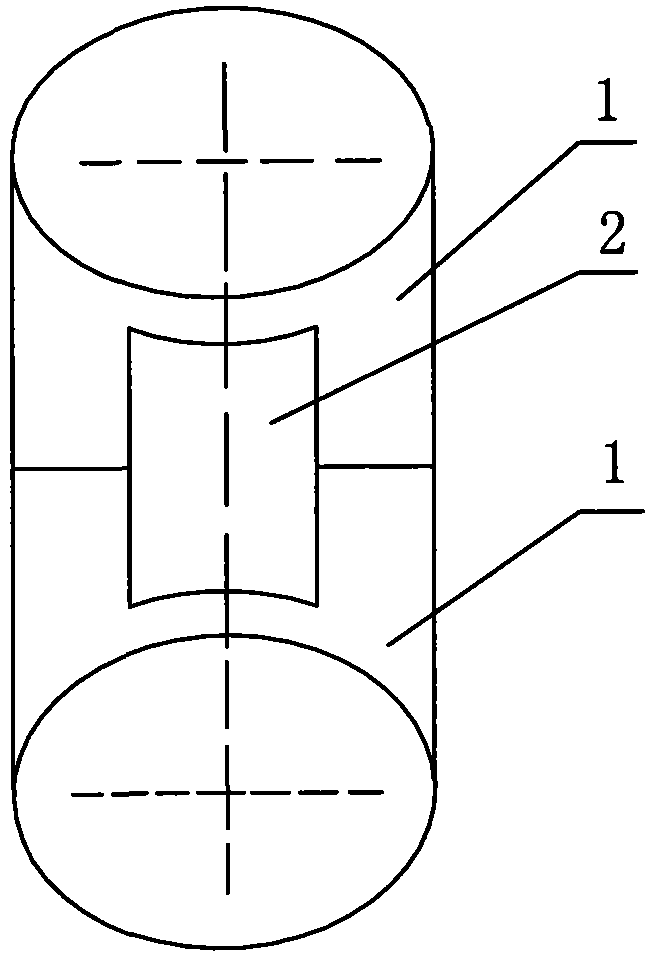

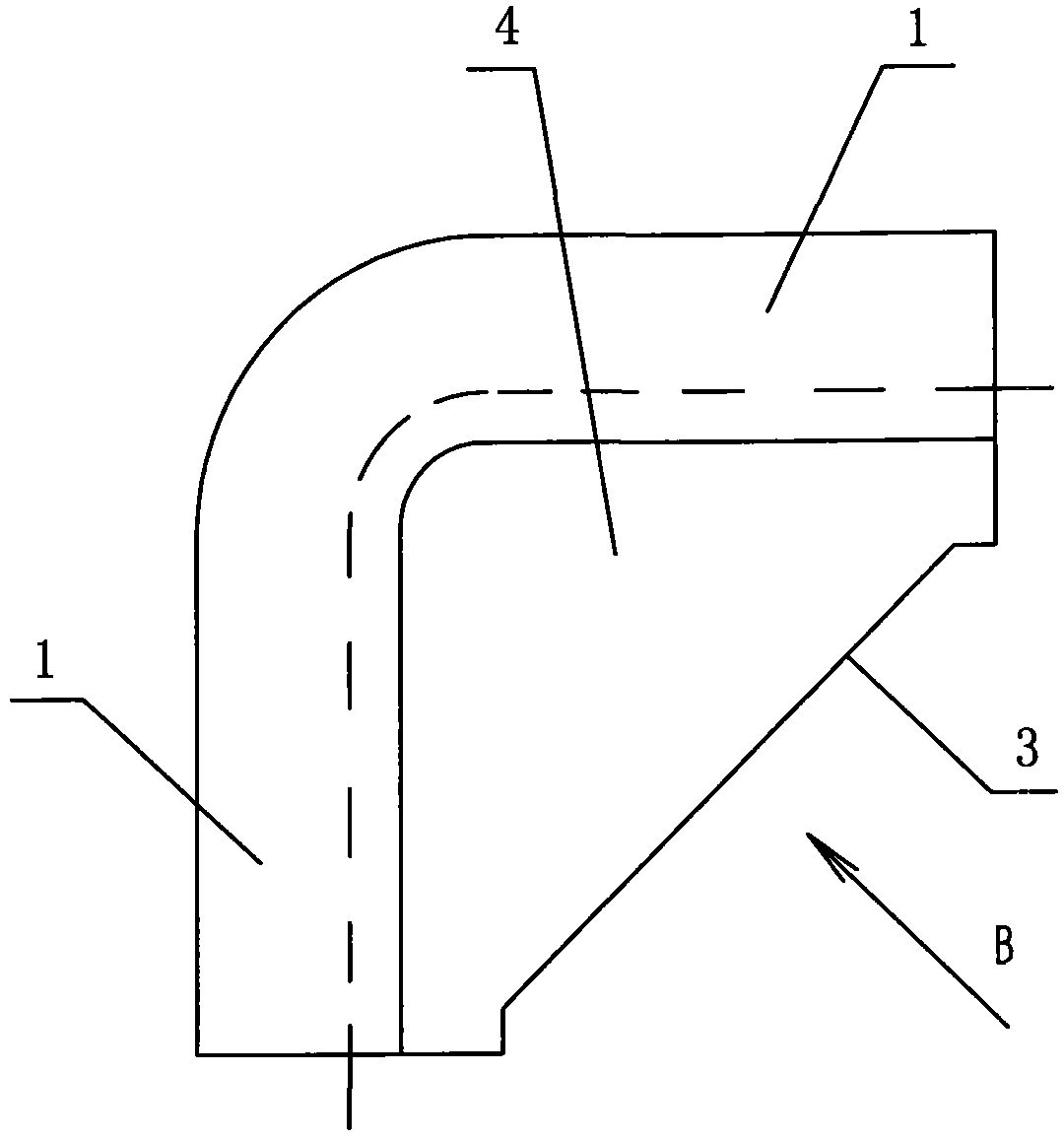

[0030] A structure of the multi-purpose pipeline elbow of the present invention comprises two sections of straight pipe 1, the distance from the center of the nozzle of the two sections of straight pipe 1 to the vertical foot is equal, the two sections of straight pipe 1 vertically intersect (penetrate), and the outside of the straight pipe 1 is semicircle The outer corner of the circular arc transition at the point where the circumference intersects, the inner half circle of the straight pipe 1 intersects to form an inner angle of 90°, and the inner half circle of the two straight pipes 1 is respectively centered with an axial notch 2, and the inner ends of each notch 2 are connected. The outer end of the mouth 2 stops at the nozzle edge of the corresponding straight pipe 1, and each side end of each notch 2 does not e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com