Patents

Literature

55results about How to "Easy to walk through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

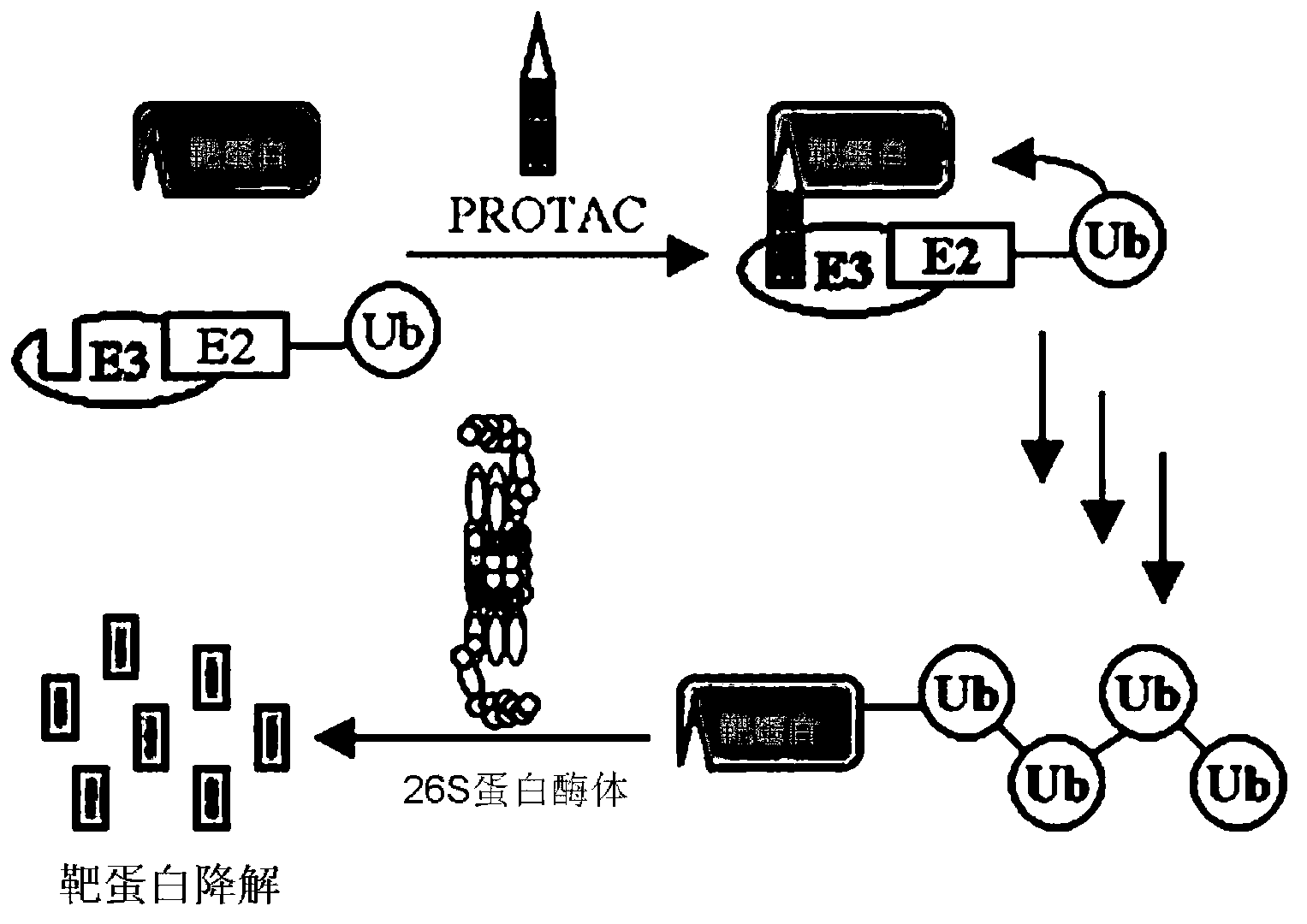

Universal construction method for protein-targeting chimeric molecule compound

InactiveCN103265635AReduce the numberImprove discovery efficiencyHybrid peptidesSpecial data processing applicationsChemical synthesisUniversal construction

The invention discloses a universal construction method for a protein-targeting chimeric molecule compound. The objective of the invention is to provide a method for adjusting the level of proteins by degrading the proteins through targeted ubiquitination. The construction method mainly comprises the following steps: 1) locating and analyzing a three-dimensional structure of a target protein and predicting active sites; 2) selecting a compound database; 3) virtually screening ligand compounds having high degrees of adaption to the target protein by using a computer; 4) acquiring the screened ligand compounds and screening an optimal ligand compound of the target protein through detection of interaction between micromolecules and the proteins; 5) constructing a protein-targeting chimeric molecule compound composed of the optimal ligand compound of the target protein, ubiquitin ligase E3 identification ligand and Linker connecting the optimal ligand compound of the target protein to the ubiquitin ligase E3 identification ligand by using a combination manner simulated by the computer; and 6) chemically synthesizing the protein-targeting chimeric molecule compound. With the method provided by the invention, the protein-targeting chimeric molecule compound can be rapidly and highly efficiently prepared, and specific degradation of intracellular target proteins is realized.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

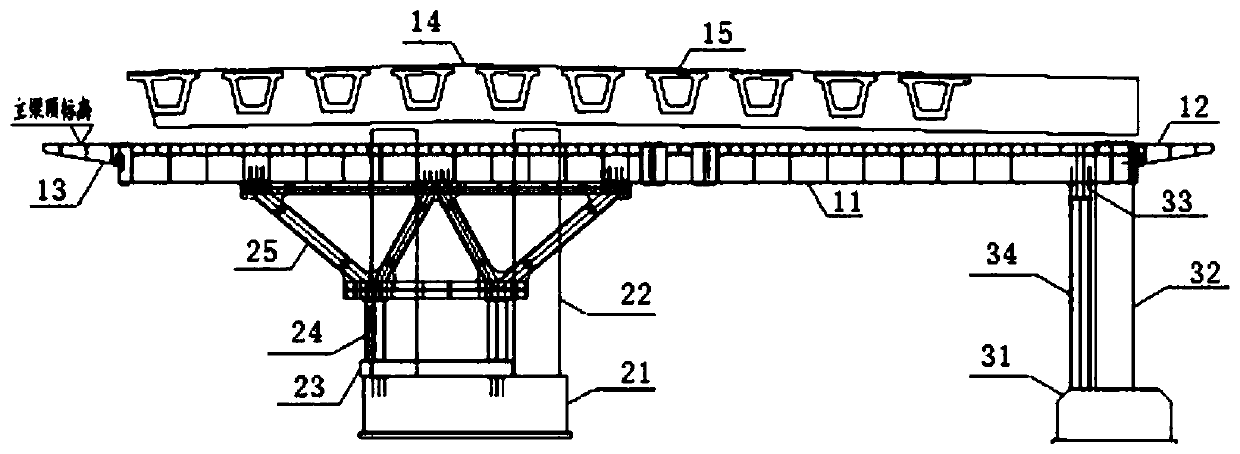

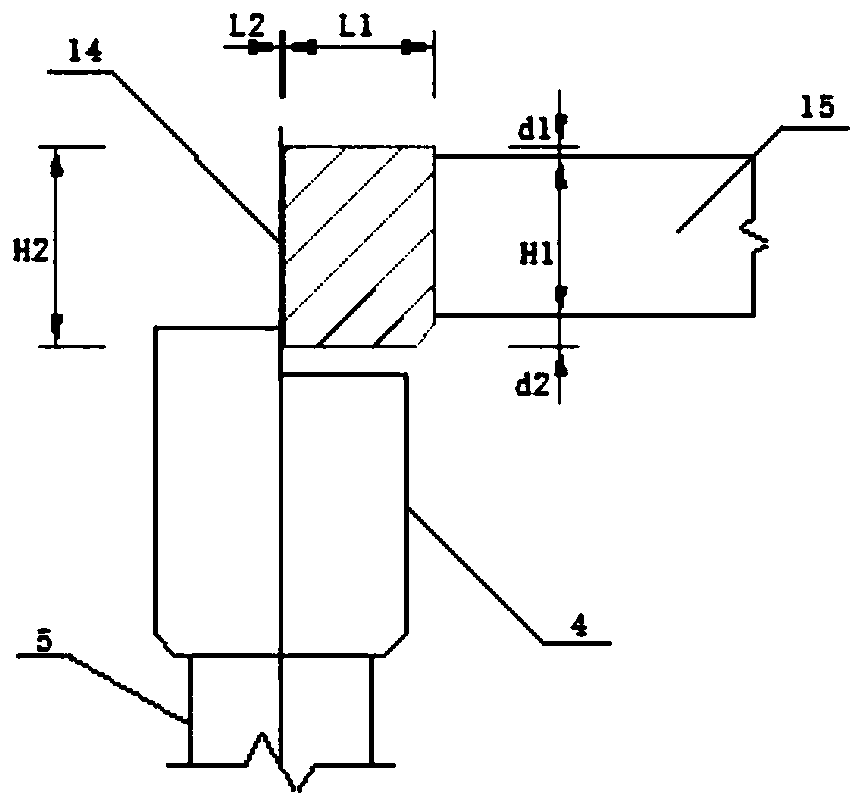

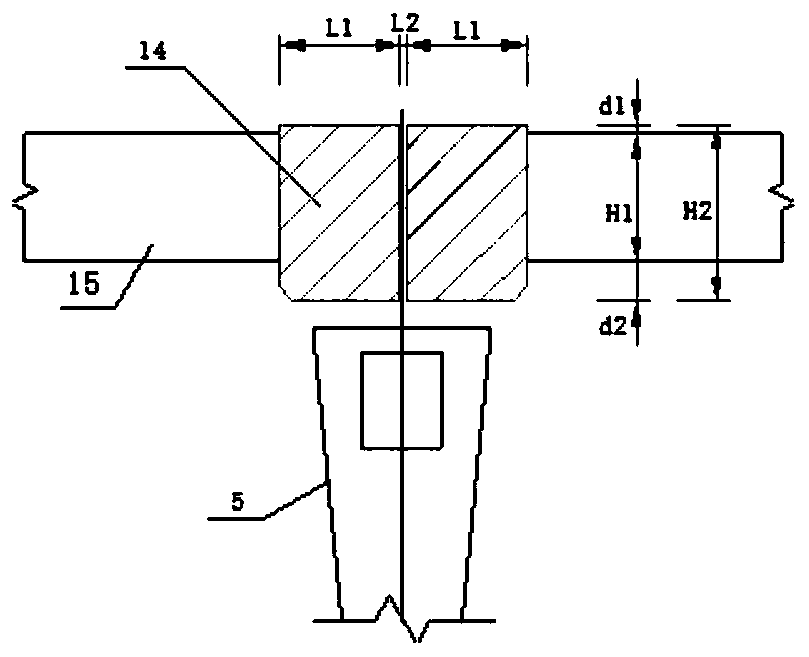

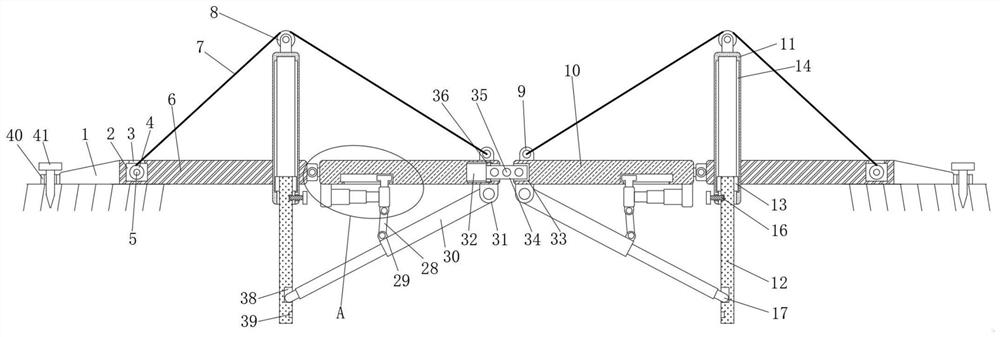

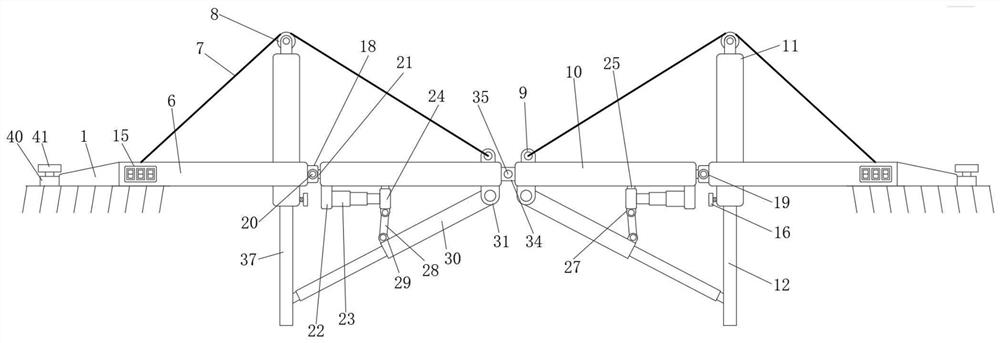

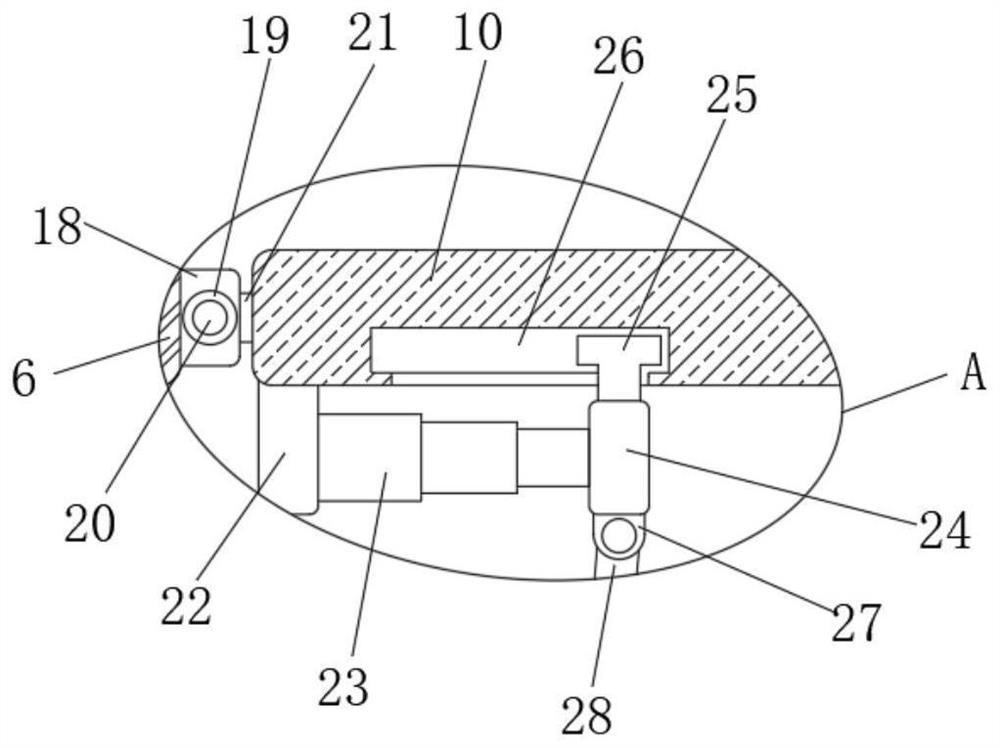

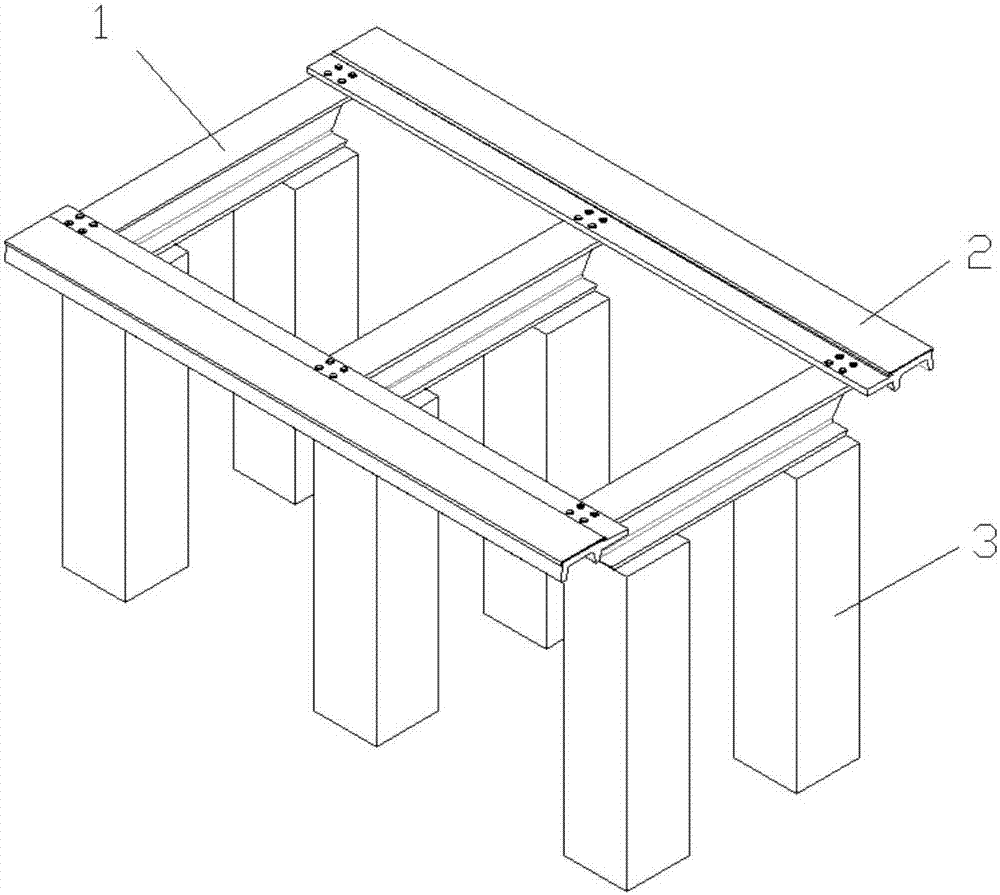

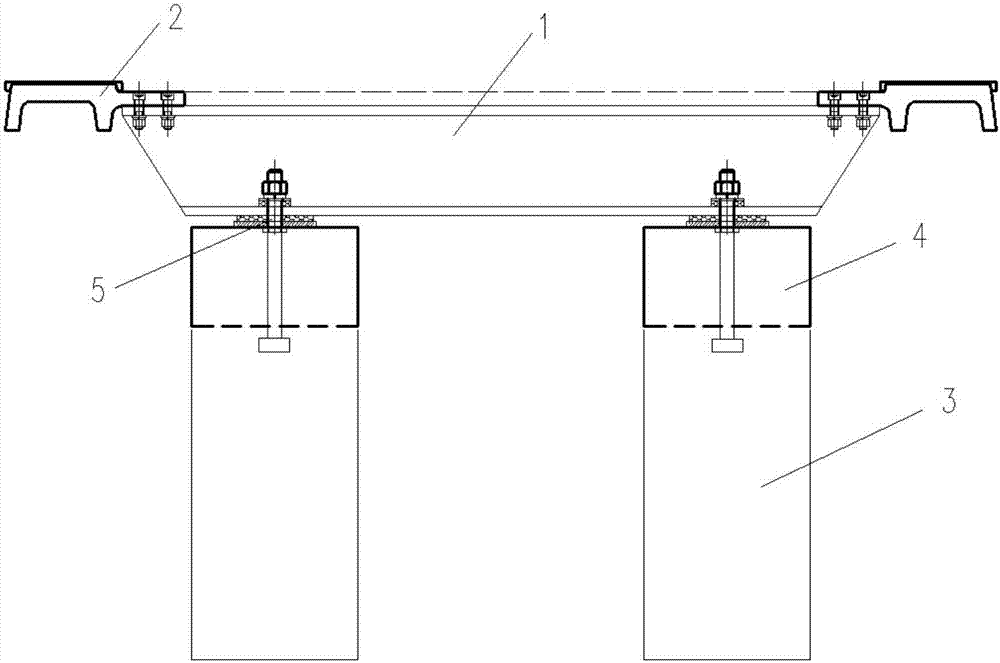

Road bridge prefabricated small box girder type invisible cap beam temporary support system and construction method thereof

ActiveCN110747746AEasy to liftEasy to assemble and disassembleBridge structural detailsBridge erection/assemblySupporting systemArchitectural engineering

The invention discloses a road bridge prefabricated small box girder type invisible cap beam temporary support system and a construction method thereof. The support system comprises a main beam, a main pier supporting system and a side pier supporting system, wherein the main beam is arranged along the transverse side of a road bridge pier; the main pier supporting system is arranged on the transverse side of a main pier area and located below the main beam, the lower end of the main pier supporting system is fixed with a main pier bearing platform, and the upper end of the main pier supporting system is fixed with the main beam; and the side pier supporting system is arranged on the transverse side of a side pier area and located below the main beam, and the lower end of the side pier supporting system is fixed with a side pier bearing platform, and the upper end of the side pier supporting system is fixed with the main beam. Therefore, the support system only has a large cross-diameter support beam (main beam) between the transverse main pier area and the side pier area, and other support systems arranged in the vertical direction are not present, so that a vehicle operation space is provided, and disassembly and assembly of the prefabricated small box girder type invisible cap beam support system are convenient. In addition, the support system has the characteristics of highbearing capacity so as to meet the supporting requirements of the prefabricated small box girder type invisible cap beam.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP

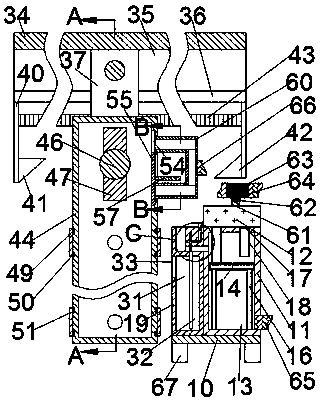

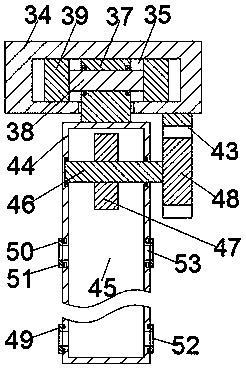

Walking chassis and high-altitude operation vehicle with same

PendingCN108082280AFlexible and convenientFlexible steeringSteering linkagesDrive wheelSteering control

The invention discloses a walking chassis comprising a chassis body, at least two sets of wheel sets are arranged at the bottom of the chassis body, each set of the wheel sets comprises two wheels, and each set of the wheel sets is connected with a steering drive device for driving wheels to steer; and the steering drive is in communicative connection with a steering controller so that the steering controller controls all wheels to rotate synchronously. All the wheel sets of the walking chassis are connected with the steering drive device, and the steering drive device is communicatively connected with the steering controller. Therefore, a control command can be sent to the steering drive device through the steering controller so that the steering drive device can drive all the wheels forsynchronous rotation to realize that the walking chassis run obliquely and transversely, and the walking chassis is allowed to be flexibly and easily accessible in any narrow site. The invention alsodiscloses a high-altitude operation vehicle with the walking chassis, the high-altitude operation vehicle can flexibly steer, realizes oblique walking and lateral walking, and convenient walking in any complicated site is achieved.

Owner:HUNAN SINOBOOM HEAVY IND

Steel tube concrete column high-altitude construction safety protection system

ActiveCN102912996AEasy and fast assembly and disassemblyQuick and easy disassemblyBuilding material handlingScaffold accessoriesProtection systemSteel tube

The invention discloses a steel tube concrete column high-altitude construction safety protection system which comprises a safety operation platform for executing concrete casting work on a steel tube column of the current layer and executing welding work on a steel tube column of the last layer, a safety climbing ladder which is welded on the outer sides of the steel tube columns and is used for making a constructor climb up and down the operation platform, and temporary packways which are fixed on two adjacent steel tube columns and are connected to the two adjacent steel tube columns, wherein the operation platform is a cage body fixedly arranged at an opening above the top of each steel tube column; the cage body can be split off and is separated from the steel tube columns; and a detachable supporting bracket for supporting the cage body are arranged on the top of each layer of steel tube column. By utilizing the technical scheme, the operation platform is mounted and dismounted quickly and easily and can be reused for casting the concrete to the steel tube columns; materials are saved; the operation platform, the safety climbing ladder and the temporary packways form a complete high-altitude construction three-dimensional protection system; the efficiency of steel tube concrete column construction is improved; and the working period is saved.

Owner:GUANGZHOU JISHI CONSTR GRP +1

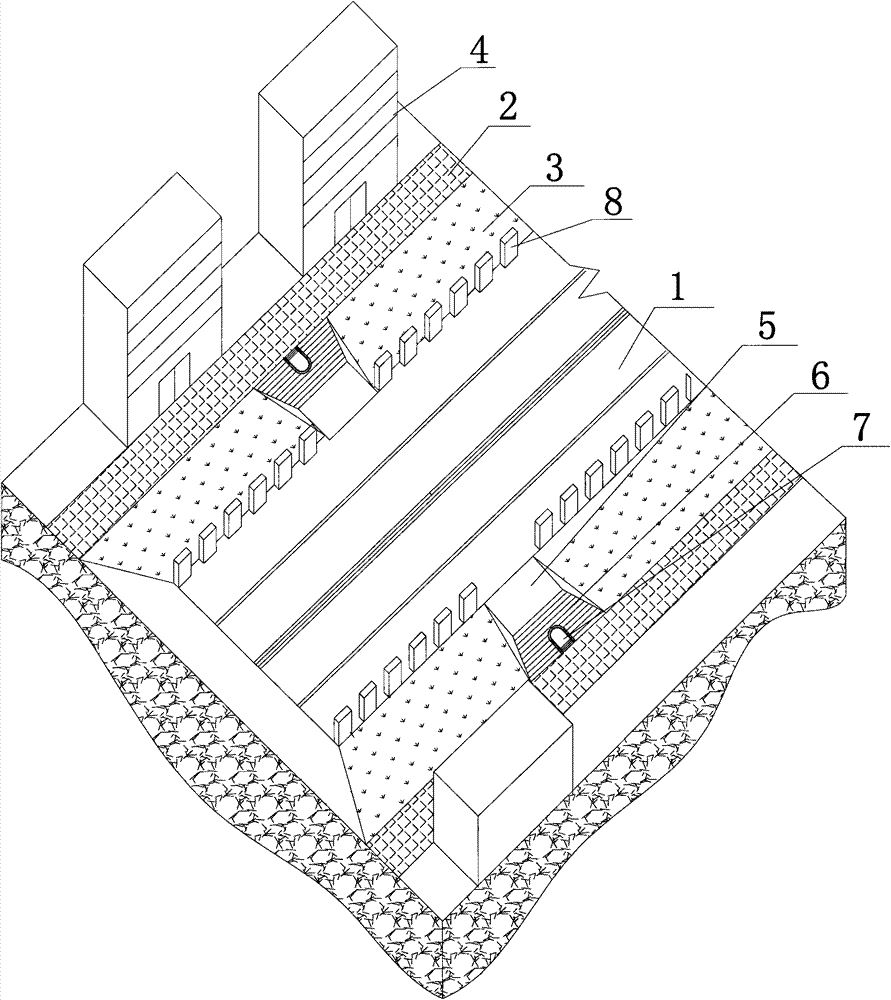

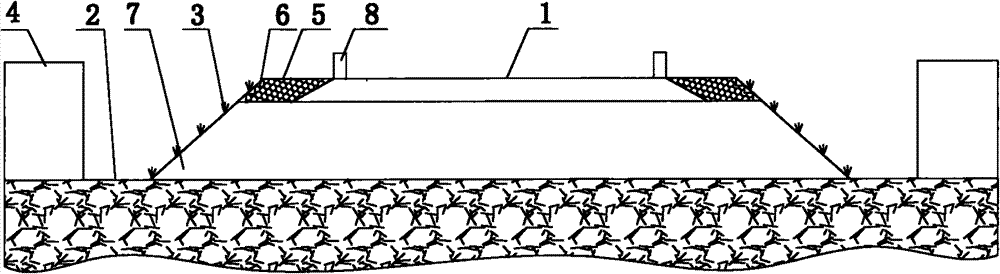

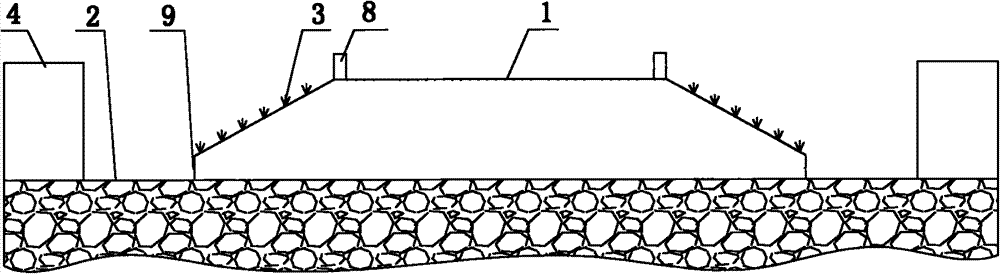

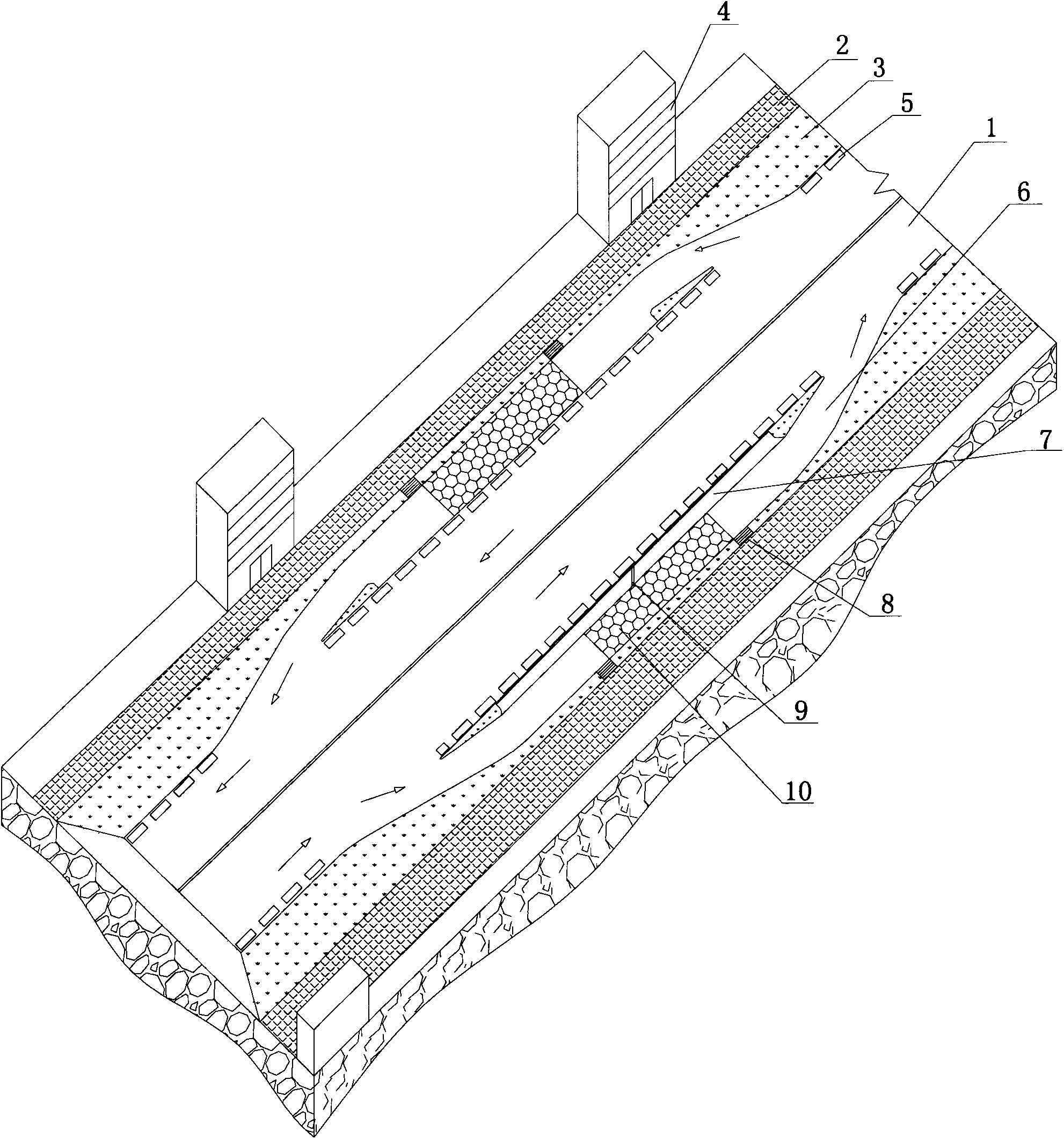

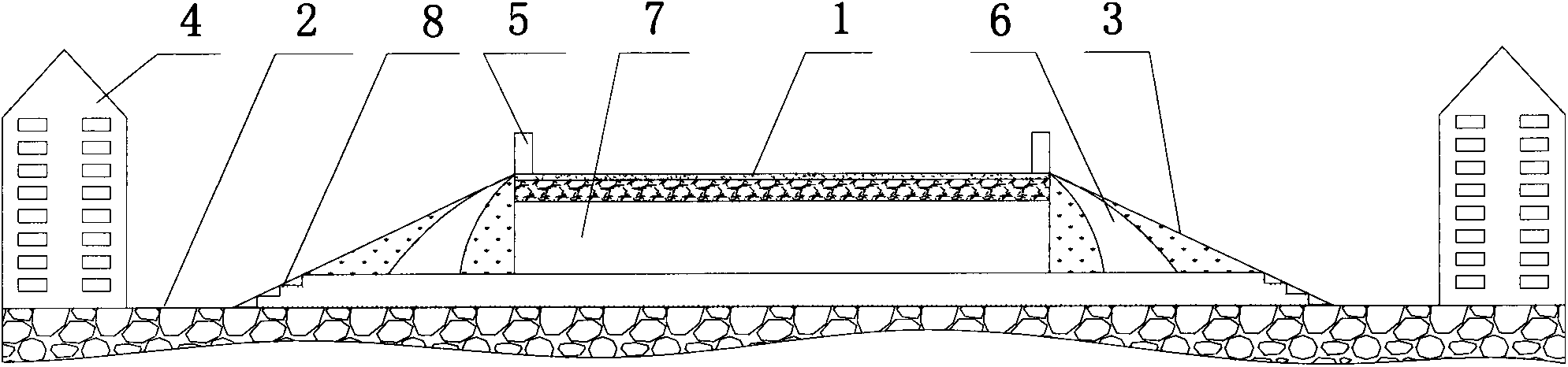

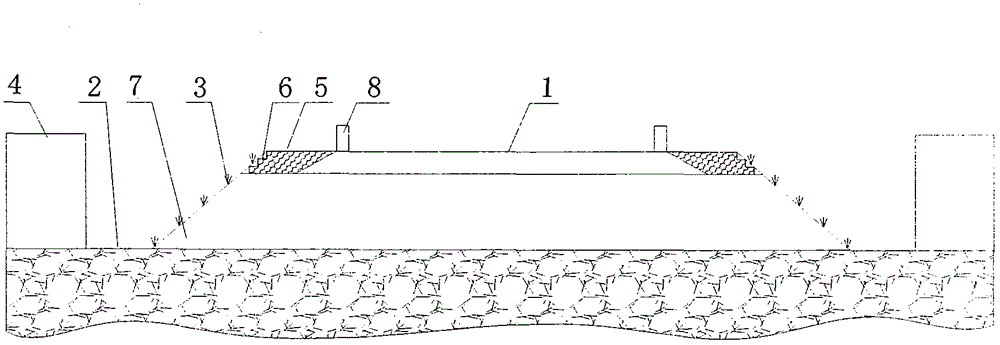

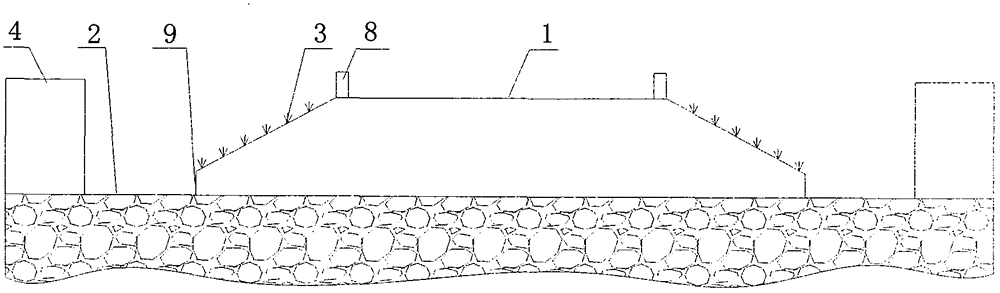

Urban road separating pedestrians from vehicles

InactiveCN103485251ASolve the phenomenon of mixed use of people and vehiclesImprove securityRoadwaysClimate change adaptationTraffic accidentEngineering

The patent of the invention discloses an urban road separating pedestrians from vehicles. All the components of the cross section of the urban road are not arranged on one horizontal plane, and are designed into concave or convex trapezoidal cross sections; green belts are designed into inclined planes meeting the head room of sidewalks to separating vehicles from pedestrians, so that motor vehicles driven on the bottom surfaces or (the top surfaces) and pedestrians walking on the top surfaces or (the bottom surfaces) have different ways and are not mutually interfered; pedestrian posterns or pedestrian footbridges are arranged at intersections, and pedestrian zebra crossings and pedestrian traffic lights are needless. The urban road separating pedestrians from vehicles avoids the phenomenon that the pedestrians and the vehicles are crowded in the same road, avoids traffic accidents of the pedestrians and the vehicles, provides convenience for the old, children, the disabled and other people in crossing the road, reduces damage to human beings caused by traffic pollution such as exhaust gas, noises, vibration and dust, and facilitates laying, repairing and maintaining various urban pipelines.

Owner:XIANGTAN UNIV

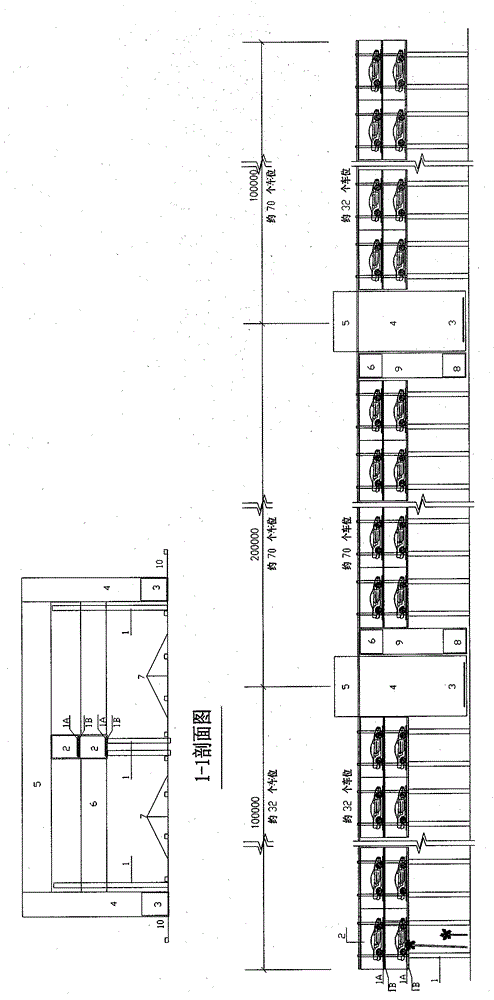

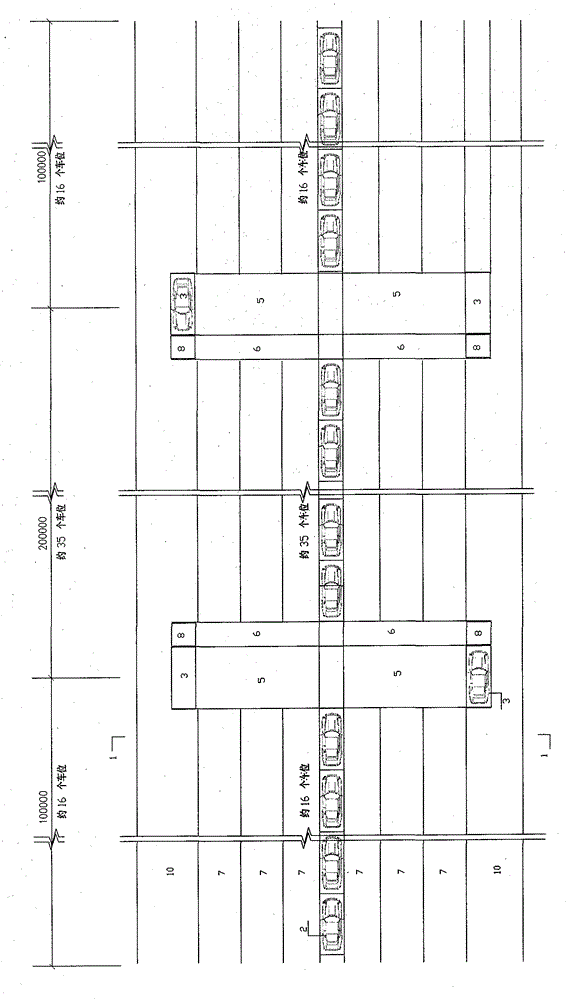

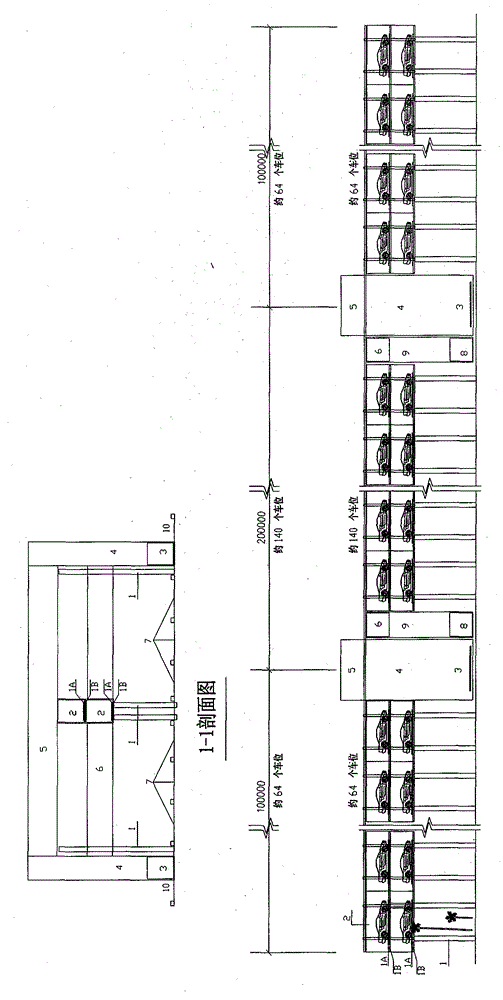

City road intelligent type multifunctional stereo garage

InactiveCN105041022ADoes not occupy land resourcesSafe for pedestrians to cross the roadParkingsAutomotive engineeringReinforced concrete

The invention provides a city road intelligent type multifunctional stereo garage capable of extending along city roads so as to be segmented or arranged in a whole segment; the garage can be used for parking cars, allows pedestrians to cross, and can serve as an emergency road for vehicle, thus fully utilizing technical features of the stereo garage, and combining with a city two-way road center isolation rail or isolation greenbelt; the garage uses steel structures and reinforced concrete structures to replace the center isolation rail and the isolation greenbelt and to serve as bottom supporting and fixing devices of the stereo garage. The vehicle enters entrances / exits on two sides of the road, passes a vertical convey path or a horizontal convey path, and then is parked in the city road intelligent type multifunctional stereo garage extending along city roads so as to be segmented or arranged in whole segment; in special conditions, the stereo garage convey paths can serve as vehicle convey emergency paths; pedestrians can use pedestrian carrying platforms, a pedestrian vertical transport path or a pedestrian convey path specially arranged on two sides of the road to cross the road. The garage is arranged above city two-way roads without singly occupying city land resources, thus expanding ordered reasonably construction space of stereo garage, and realizing stereo garage integration utilization purpose.

Owner:吴祖勇

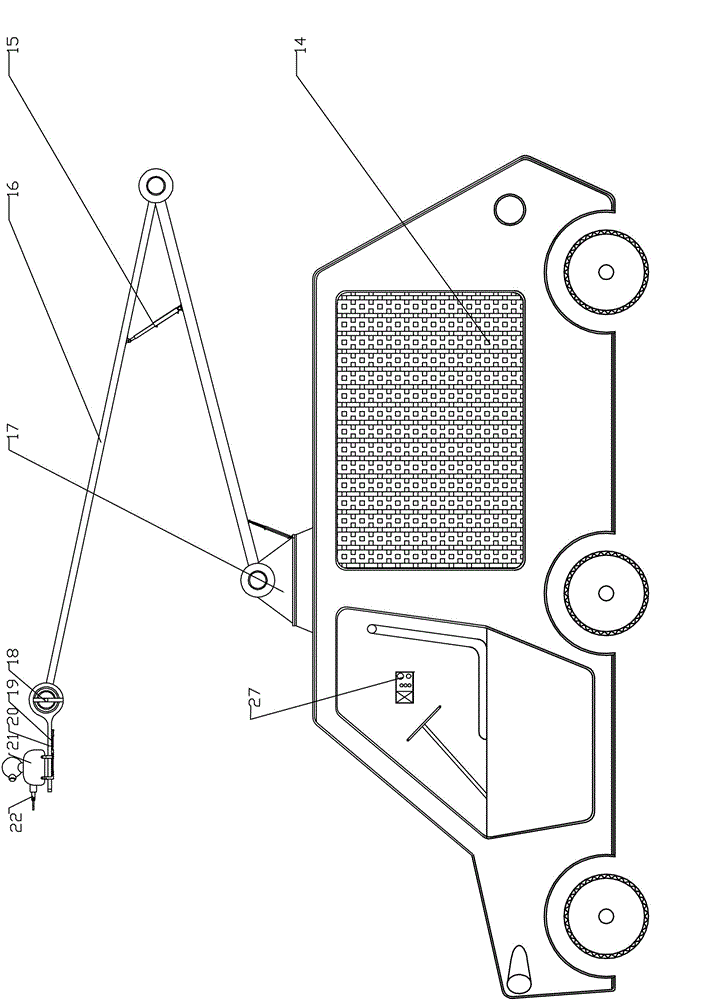

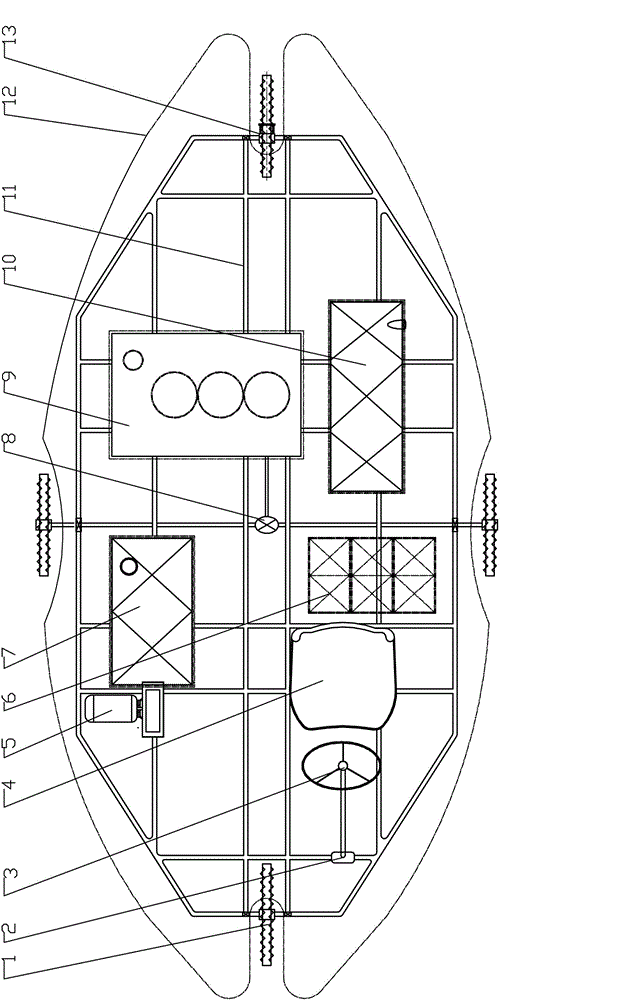

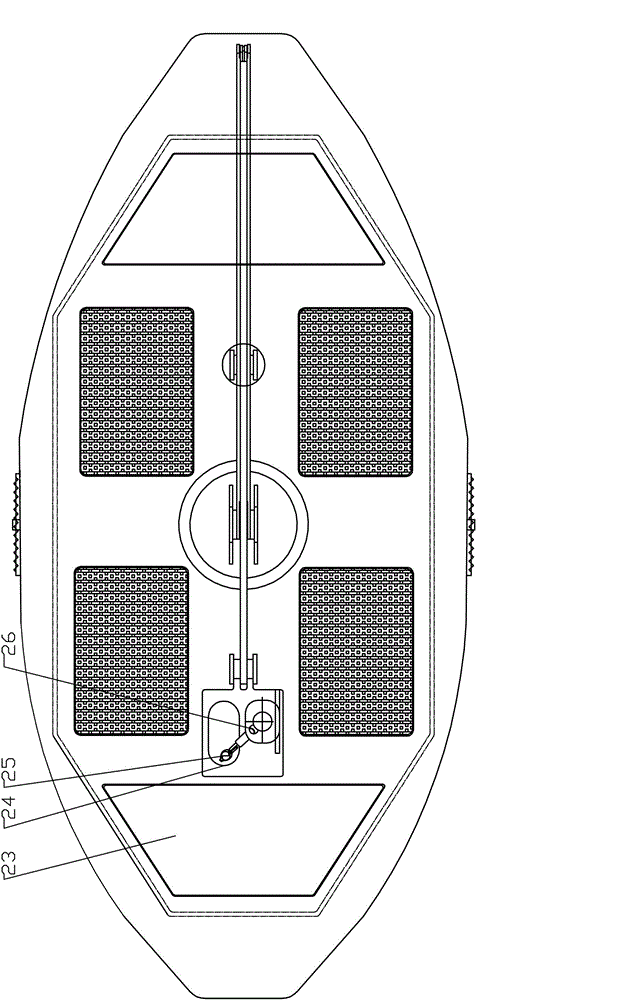

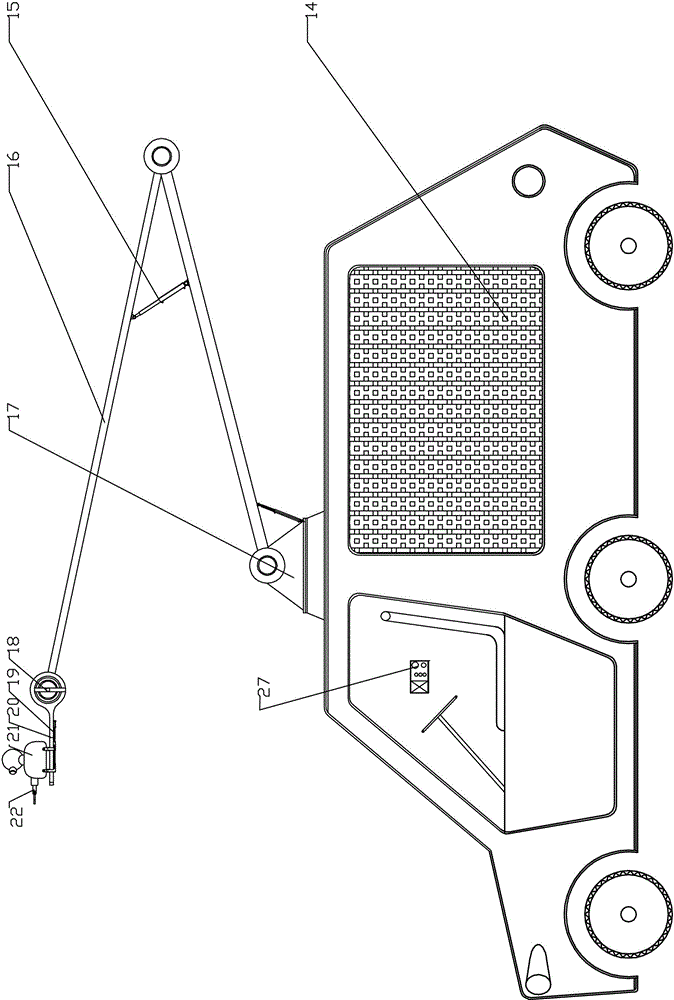

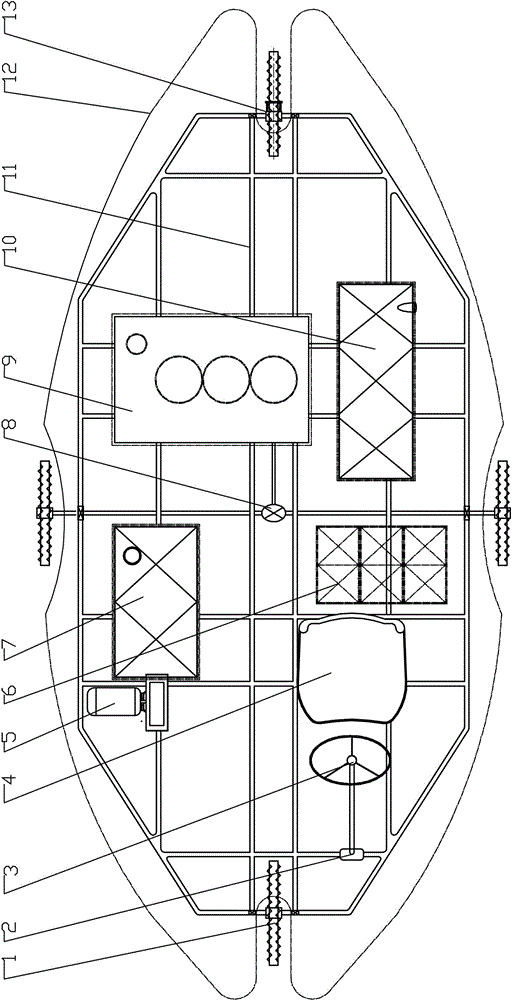

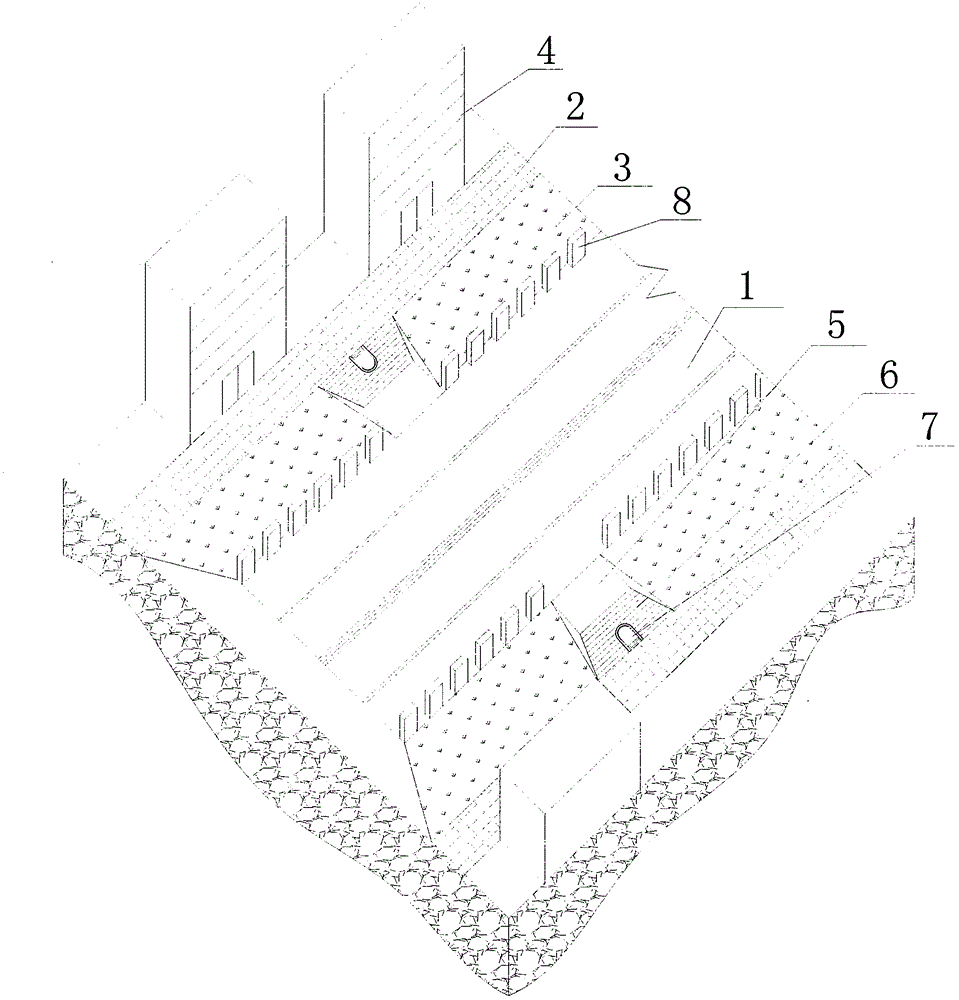

Intelligent fruit picking vehicle utilizing solar energy and oil hybrid power

InactiveCN102907216AStrong climbing abilityLarge picking areaBatteries circuit arrangementsRenewable energy machinesMobile electronicsVehicle frame

The invention relates to an intelligent fruit picking vehicle utilizing solar energy and oil hybrid power, which includes a vehicle body, a solar operating power mechanism, a hydraulic lifting mechanism, an intelligent picking mechanism, a movable digital display control mechanism and a drive traveling mechanism, wherein the vehicle body is lozenge-shaped and internally provided with a lozenge-shaped vehicle frame; two wheels are arranged at the front and the rear ends of the vehicle body respectively, and two wheels are arranged in the middle of the vehicle body; the solar operating power mechanism includes a solar panel, a battery pack, an electric control system, a hydraulic system and a hydraulic oil tank; the hydraulic lifting mechanism is arranged at the top of the vehicle body and includes a picking rotary platform, a support bracket, a lifting hydraulic cylinder and a picking platform fixing mechanism that are fixedly connected with the vehicle top; the intelligent picking mechanism is arranged on the picking platform fixing mechanism and includes a picking intelligent robot working platform, a picking intelligent robot platform traveling mechanism and a picking intelligent robot that are arranged on the intelligent picking mechanism; and the movable digital display control mechanism is movable and connected with the intelligent picking mechanism, the hydraulic lifting mechanism and the solar operating power mechanism respectively. The intelligent fruit picking vehicle utilizing solar energy and oil hybrid power is simple to operate, and is practical, efficient, environment-friendly and energy-saving.

Owner:葛立

Intelligent fruit picking vehicle utilizing solar energy and oil hybrid power

InactiveCN102907216BAdapt to field workImprove climbing abilityBatteries circuit arrangementsRenewable energy machinesHydraulic cylinderVehicle frame

The invention relates to an intelligent fruit picking vehicle utilizing solar energy and oil hybrid power, which includes a vehicle body, a solar operating power mechanism, a hydraulic lifting mechanism, an intelligent picking mechanism, a movable digital display control mechanism and a drive traveling mechanism, wherein the vehicle body is lozenge-shaped and internally provided with a lozenge-shaped vehicle frame; two wheels are arranged at the front and the rear ends of the vehicle body respectively, and two wheels are arranged in the middle of the vehicle body; the solar operating power mechanism includes a solar panel, a battery pack, an electric control system, a hydraulic system and a hydraulic oil tank; the hydraulic lifting mechanism is arranged at the top of the vehicle body and includes a picking rotary platform, a support bracket, a lifting hydraulic cylinder and a picking platform fixing mechanism that are fixedly connected with the vehicle top; the intelligent picking mechanism is arranged on the picking platform fixing mechanism and includes a picking intelligent robot working platform, a picking intelligent robot platform traveling mechanism and a picking intelligent robot that are arranged on the intelligent picking mechanism; and the movable digital display control mechanism is movable and connected with the intelligent picking mechanism, the hydraulic lifting mechanism and the solar operating power mechanism respectively. The intelligent fruit picking vehicle utilizing solar energy and oil hybrid power is simple to operate, and is practical, efficient, environment-friendly and energy-saving.

Owner:葛立

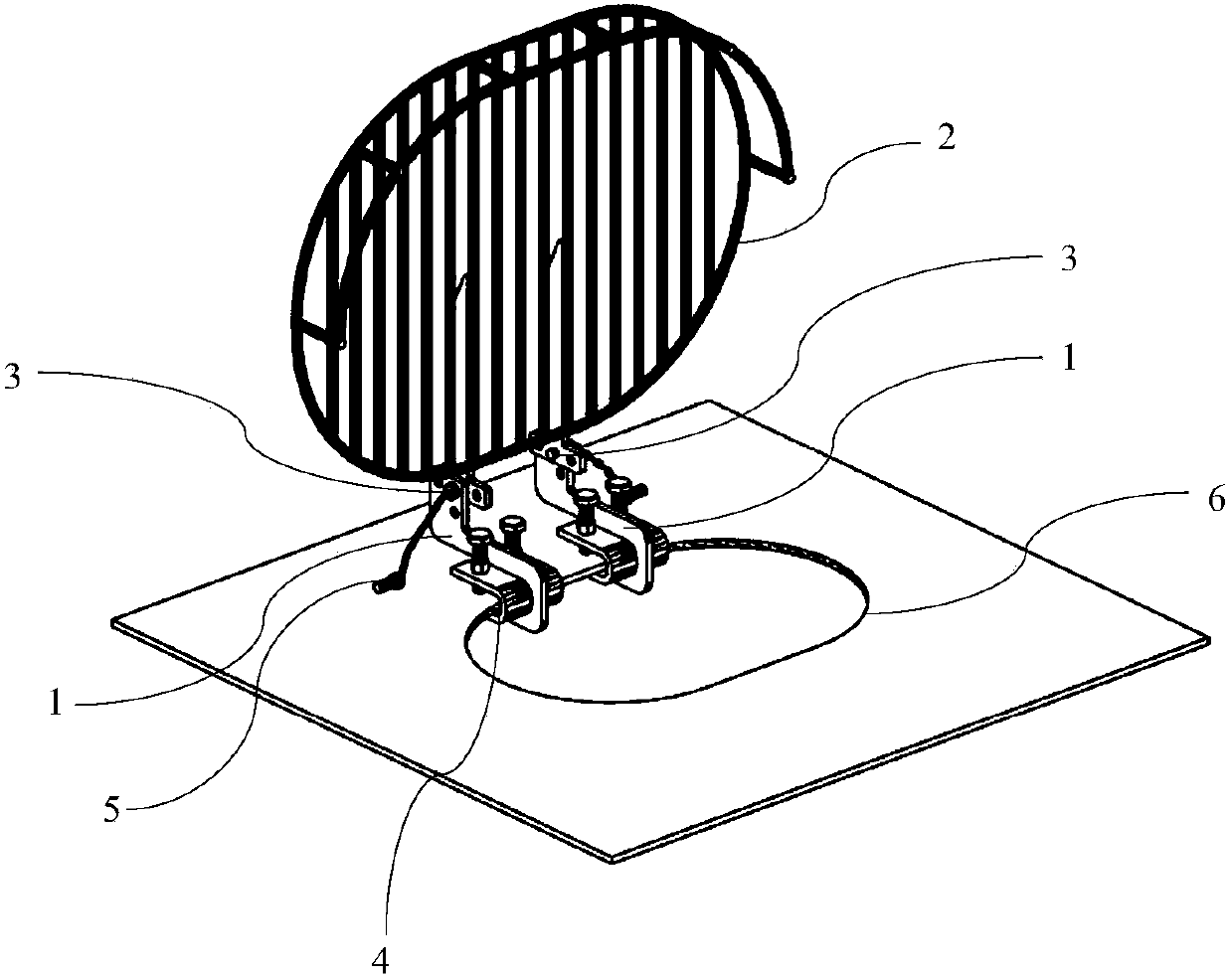

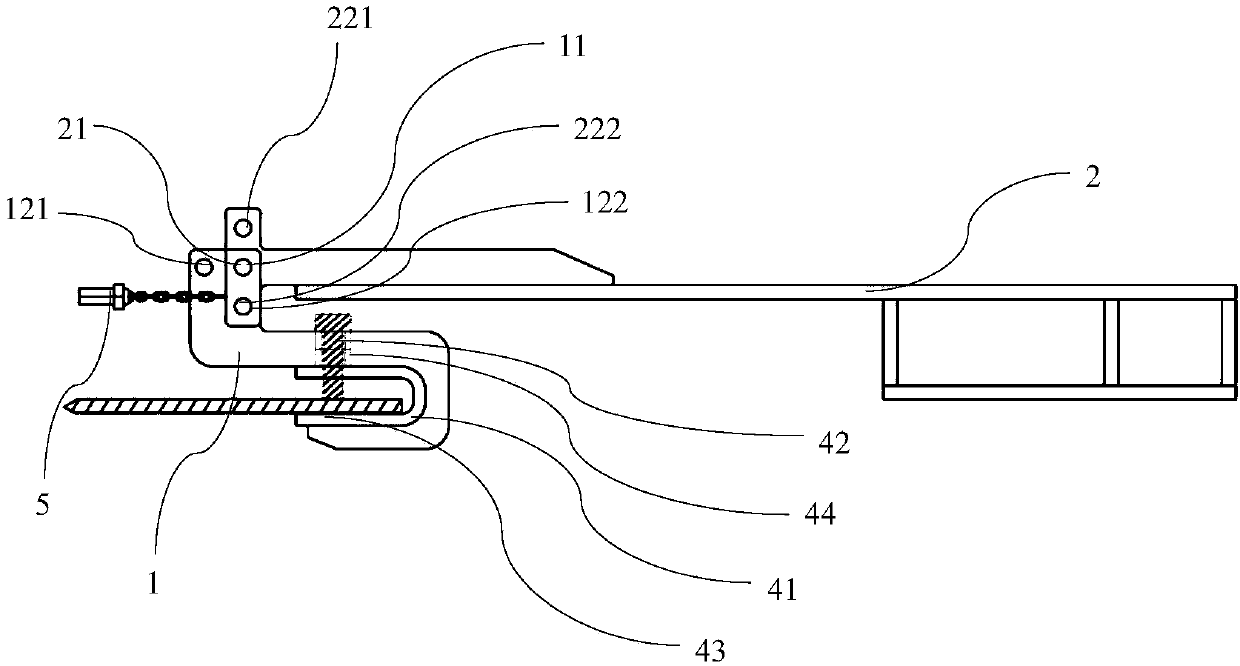

Detachable anti-falling device

PendingCN107757819AEnsure safetyEasy to walk throughVessel designingBiochemical engineeringBuilding construction

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

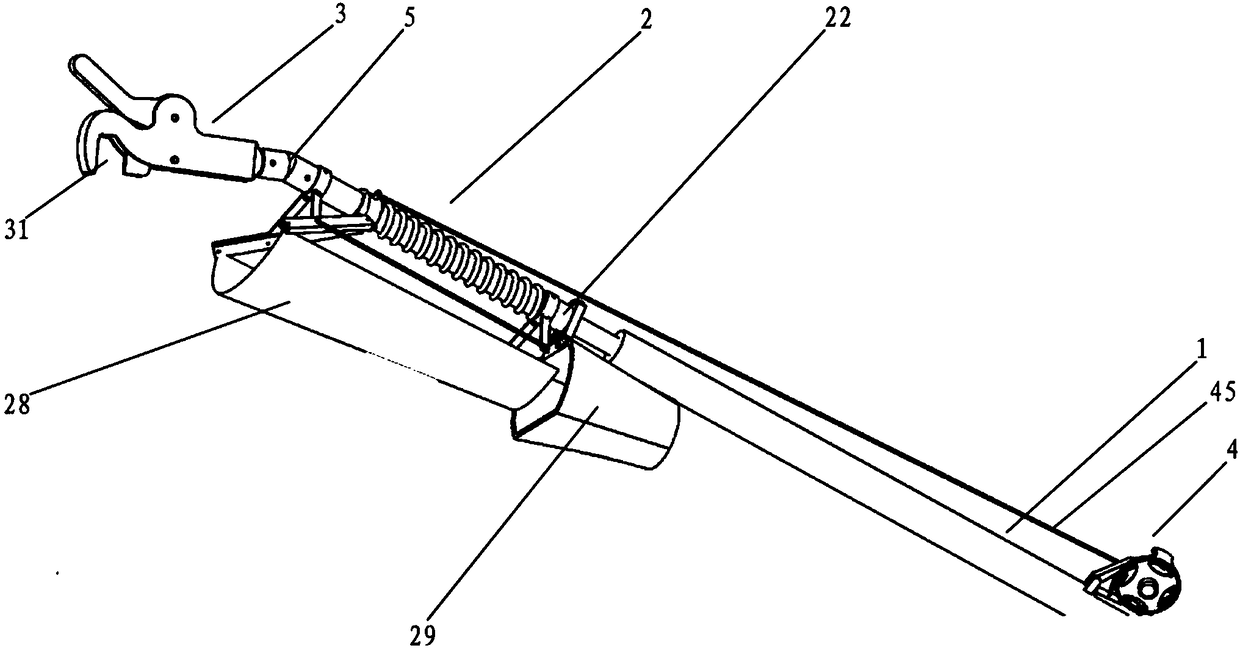

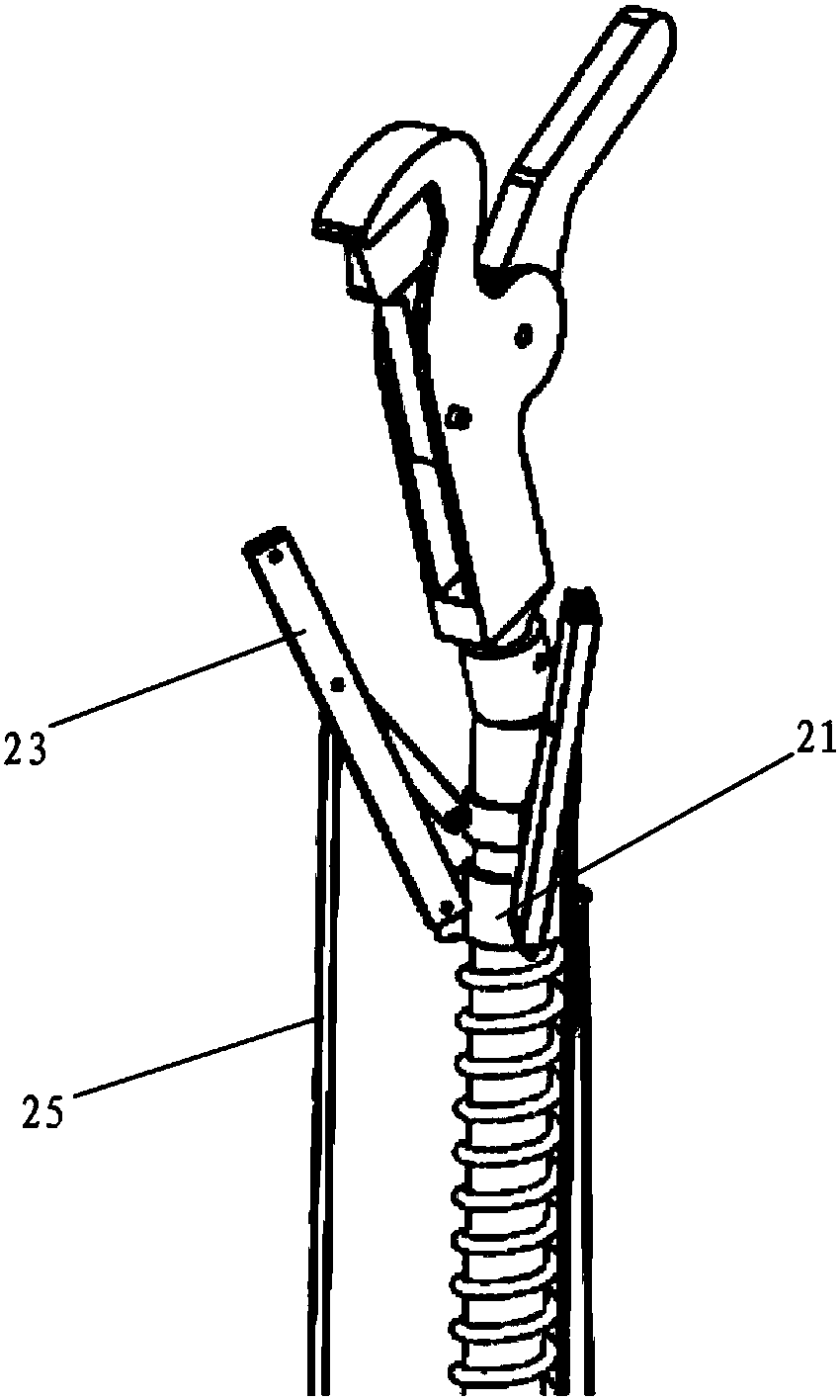

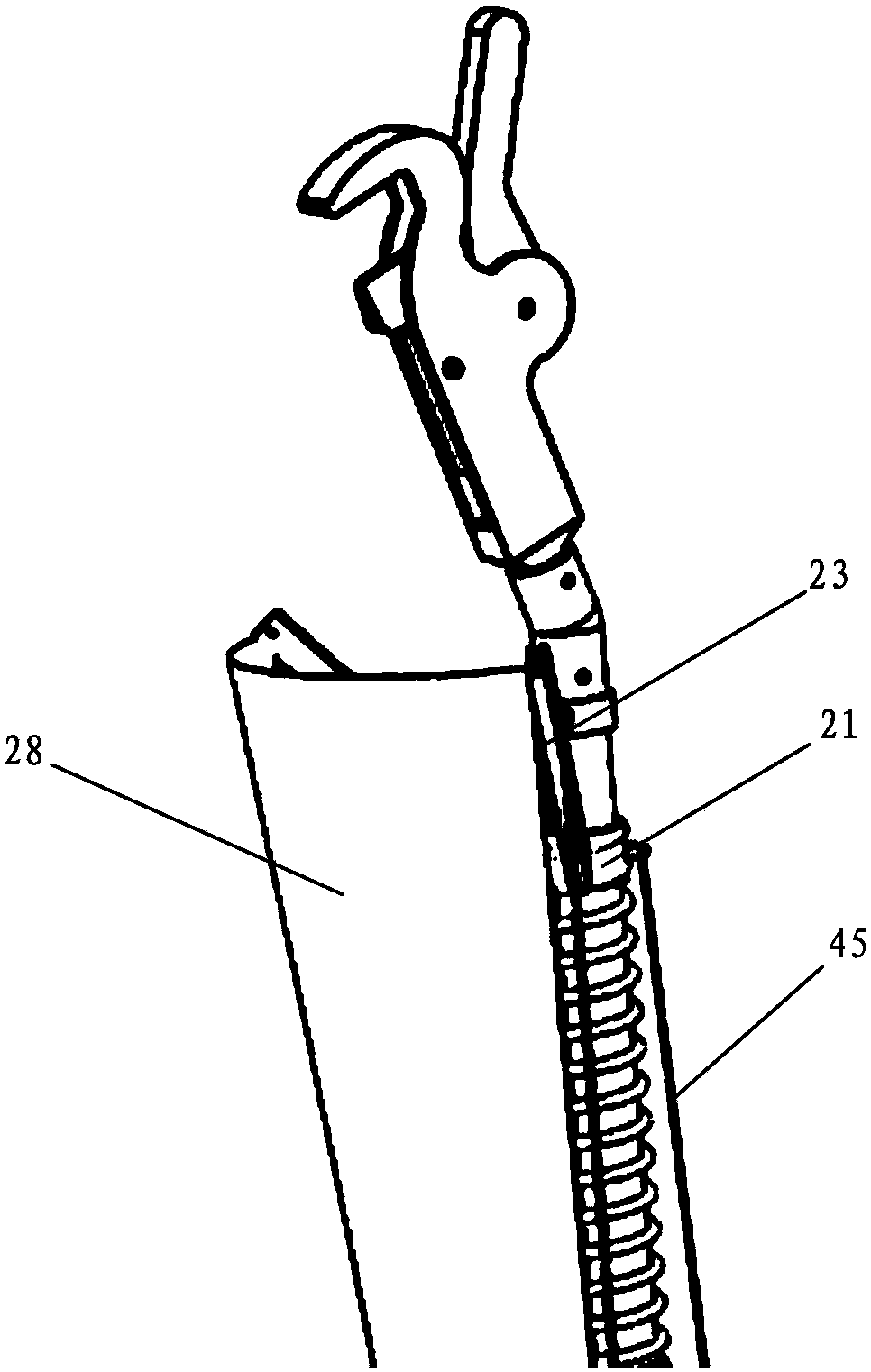

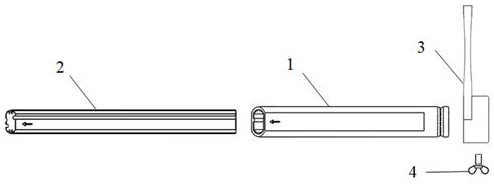

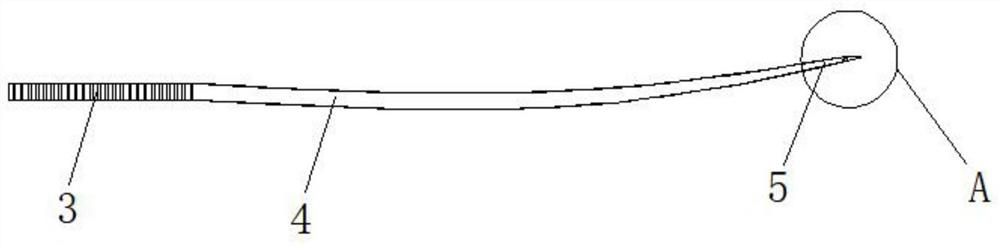

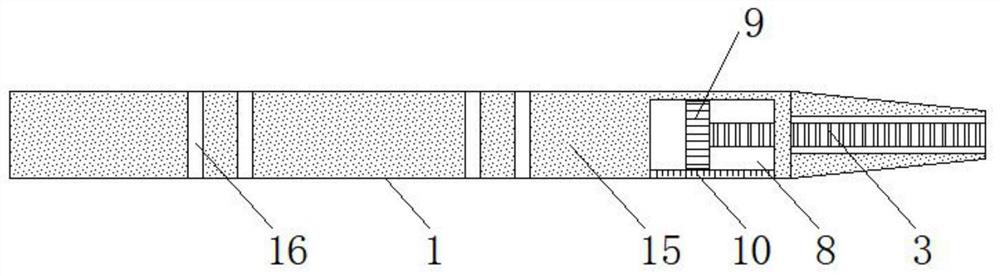

Handheld fruit picker provided with long telescopic rod

The invention discloses a handheld fruit picker provided with a long telescopic rod. The handheld fruit picker comprises the telescopic rod, a collection device, a cutting device and a drive device, wherein the cutting device and the collection device are mounted at the front end of the telescopic rod, and a power output end of the drive device is connected with a power input end of the collectiondevice; the collection device comprises a first slider, a second slider, first support rods, second support rods, a first connecting rod, a second connecting rod, an elastic piece, bearing cloth anda storage bucket. Fruit branches are cut by the cutting device. Fruits fall on the bearing cloth and are cushioned by elasticity of the bearing cloth, thereby being not easy to damage. The bearing cloth is of an arc structure when unfolded, the fruits can slide downwards along the bearing cloth under the action of own gravity and enter the storage bucket smoothly instead of falling out from two sides of the bearing cloth, and the fruits are collected safely and efficiently. Climbing up for picking and collection the fruits in trees by the aid of a trestle ladder is not needed in the whole process, labor intensity is reduced greatly, and picking and collection are simple, convenient and safe.

Owner:GUANGDONG UNIV OF TECH

Multifunctional urban road

InactiveCN103469707ASolve parking problemSolve the problem of turning around and driving in the reverse directionRoadwaysClimate change adaptationUrban main roadRoad surface

The invention discloses a multifunctional urban road. According to the multifunctional urban road, the cross section of the urban road is designed into a convex trapezoidal cross section, greenbelts are designed into inclined planes capable of meeting a head room requirement of side pavements and separating motor vehicles from pedestrians, the motor vehicles are driven on the top surface, and the pedestrians walk on the bottom surface, so that the motor vehicles and the pedestrians move on the different ways and cannot be influenced by each other; underground passages, bus stations, up-down steps and motor vehicle up-down ramps are arranged at intersections, pedestrian zebra crossings and traffic lights are omitted, the traffic problem between the motor vehicles and the pedestrians can be avoided, the traffic accident between the pedestrians and the motor vehicles can be eliminated, various crowds including old people, children, disabled people and the like can conveniently pass through a road, and harms caused by traffic pollutions including exhaust gas, noise, vibration, dust and the like to human bodies are reduced; as parking places are arranged in the underground passages, the travelling and the parking are integrated, the utilization rate of urban lands is increased, and the multifunctional urban road is simple in structure and low in manufacturing cost and is convenient and applicable.

Owner:XIANGTAN UNIV

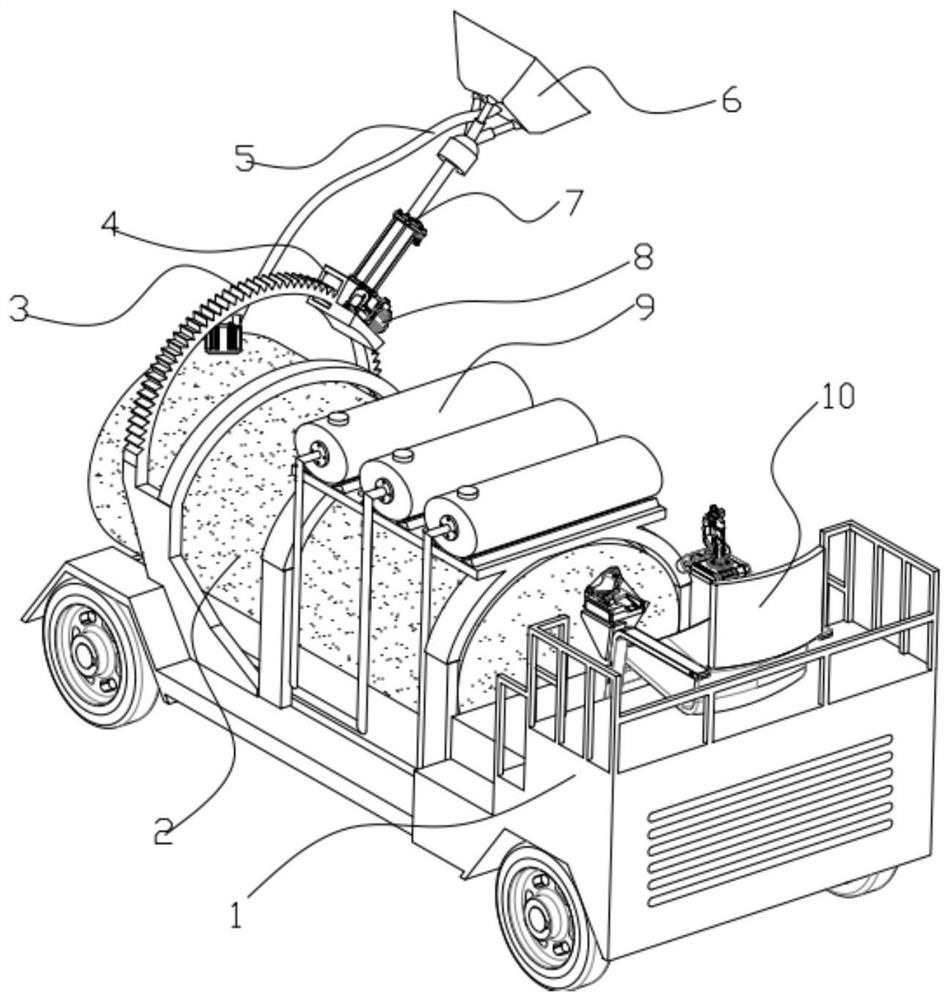

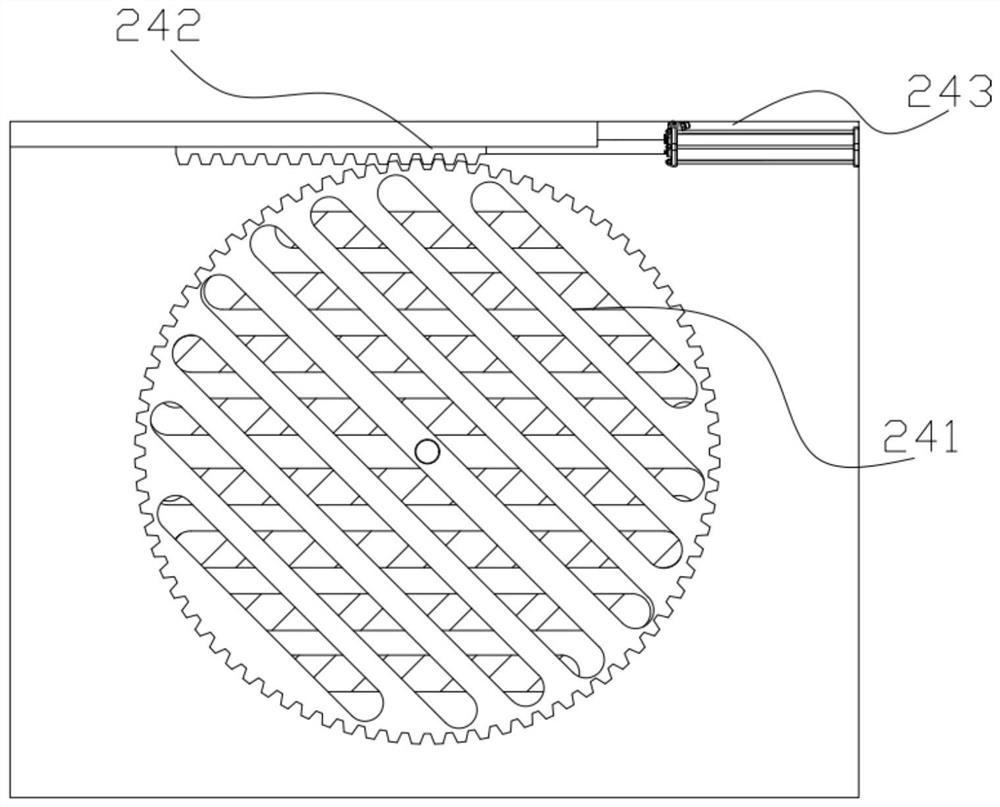

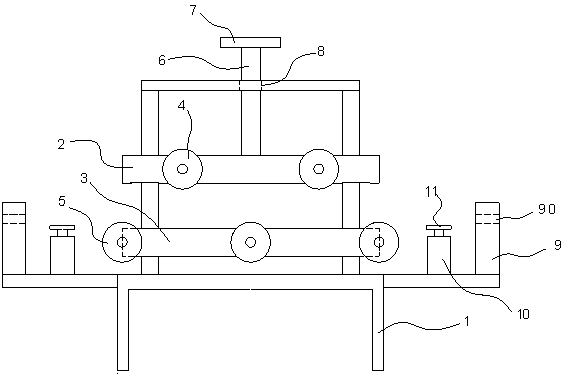

Watering device for garden construction

ActiveCN111837902AReduce sizeEasy to walk throughWatering devicesSpraying apparatusAgricultural engineeringEnvironmental geology

The invention discloses a watering device for garden construction. The watering device comprises a vehicle body, a water tank, a rack rail, a movable arm assembly and a wide-range spray head, whereinthe vehicle body is a small flat car, an operation cabin for operating equipment is arranged on the rear portion of the vehicle body, the water tank and a plurality of auxiliary water tanks are fixedon the front portion of the vehicle body, liquid in the auxiliary water tanks can be mixed with water in the water tank and then delivered into the wide-range spray head through a water pump for spraying, the movable arm assembly is movably arranged on the arc-shaped rack rail located in the vehicle body and can swing and stretch along the arc-shaped rack rail, and the wide-range spray head is arranged on the movable arm assembly and can adjust spraying of water columns with different dispersion degrees or spraying of water mist. Compared with the prior art, the watering device for garden construction is small in size, conveniently passes through a garden, and is convenient to use, water can be mixed with other liquid for spraying, the water columns with different dispersion degrees or thewater mist can be sprayed out, and the watering device for garden construction has rich functions and high applicability and is more suitable for working in a garden construction environment.

Owner:TONGLING UNIV

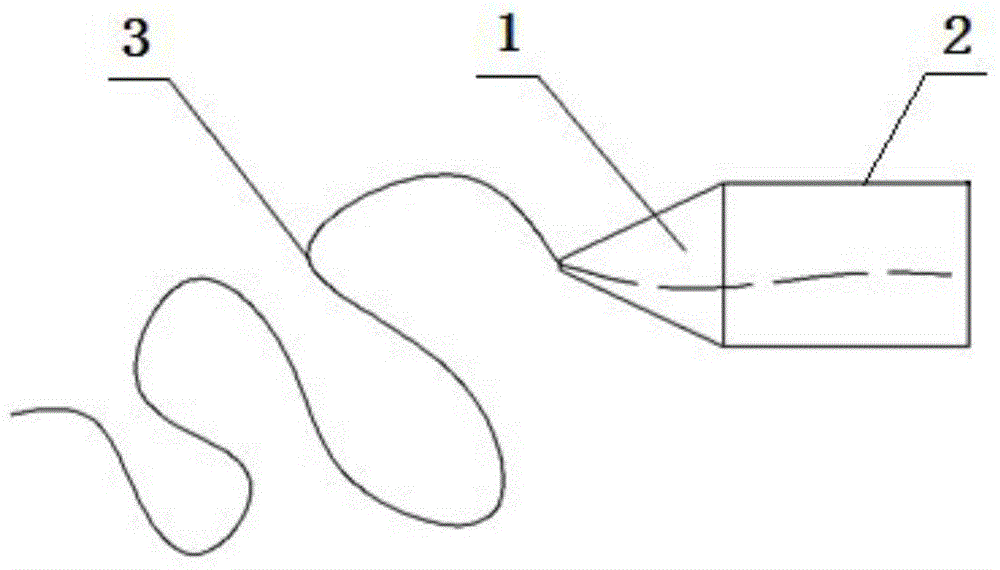

Pre-stress pipeline dredging device as well as a manufacturing and application method thereof

InactiveCN103952976ASimple structureEasy to set upBridge erection/assemblyBridge materialsPre stressPre stressing

The invention discloses a pre-stress pipeline dredging device as well as a manufacturing and application method thereof. The dredging device comprises a cone and a steel pipe connected with the bottom of the cone; a small hole is formed in the top of the cone and a steel strand is fixed through the small hole. The manufacturing and application method comprises the steps of manufacturing the dredging device, threading and fixing the steel strand through the small hole at the top of the cone in the dredging device, pulling the dredging device into a pre-stress pipeline by using the steel strand and enabling the dredging device to pass through the pipeline and the like. The pre-stress pipeline dredging device has the advantages of simple structure, convenience for arrangement, rapidness in dredging and good effect; the working requirements of all aspects of the dredged pre-stress pipeline are ensured; the pre-stress pipeline dredging device is good for repeated utilization and the construction cost is reduced.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

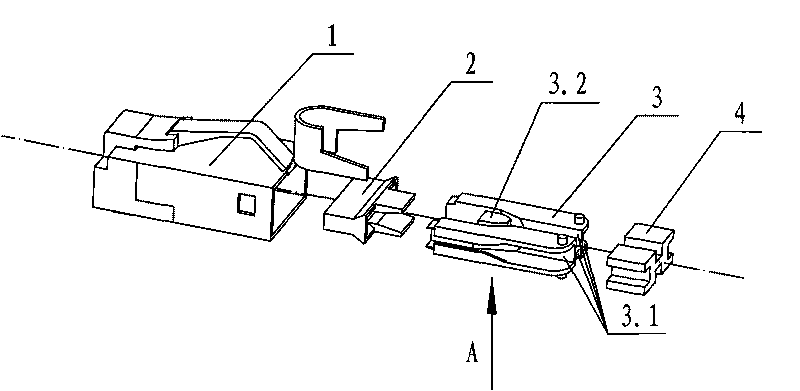

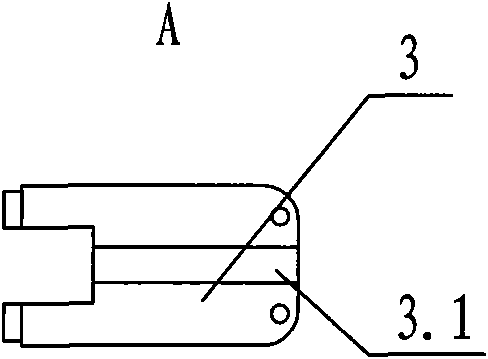

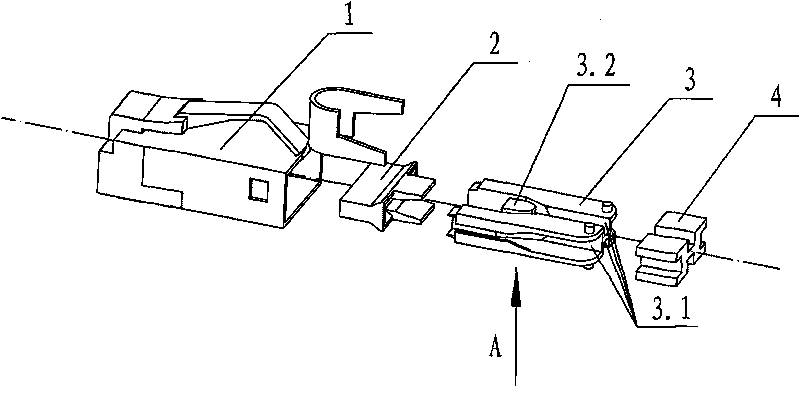

6A-shielding RJ45 crystal plug

InactiveCN101719608AMeets performance requirements for demanding shielded system cablesNot easy to looseCouplings bases/casesCoupling protective earth/shielding arrangementsEngineeringPatch cable

The invention relates to a 6A-shielding RJ45 crystal plug, comprising a crystal plug body (1) with a metal shielding shell, a wire cavity (2) in the crystal plug body (1) and a wire insert core (4) connected with the tail part of the crystal plug body (1), a branching separation piece (3) is arranged in the crystal plug body (1), one end of the branching separation piece (3) is connected with the wire cavity (2), the end surface of the other end of the branching separation piece (3) is laminated with the end surface of the wire insert core (4), and four surfaces of the branching separation piece (3) along the length direction are all provided with wiring troughs (3.1). Compared with the prior art, the 6A-shielding RJ45 crystal plug has the characteristic that the plug can meet performance requirements of cables of a high-requirement shielding system of a 6A jumper wire system.

Owner:宁波意欧迅网络通信有限公司

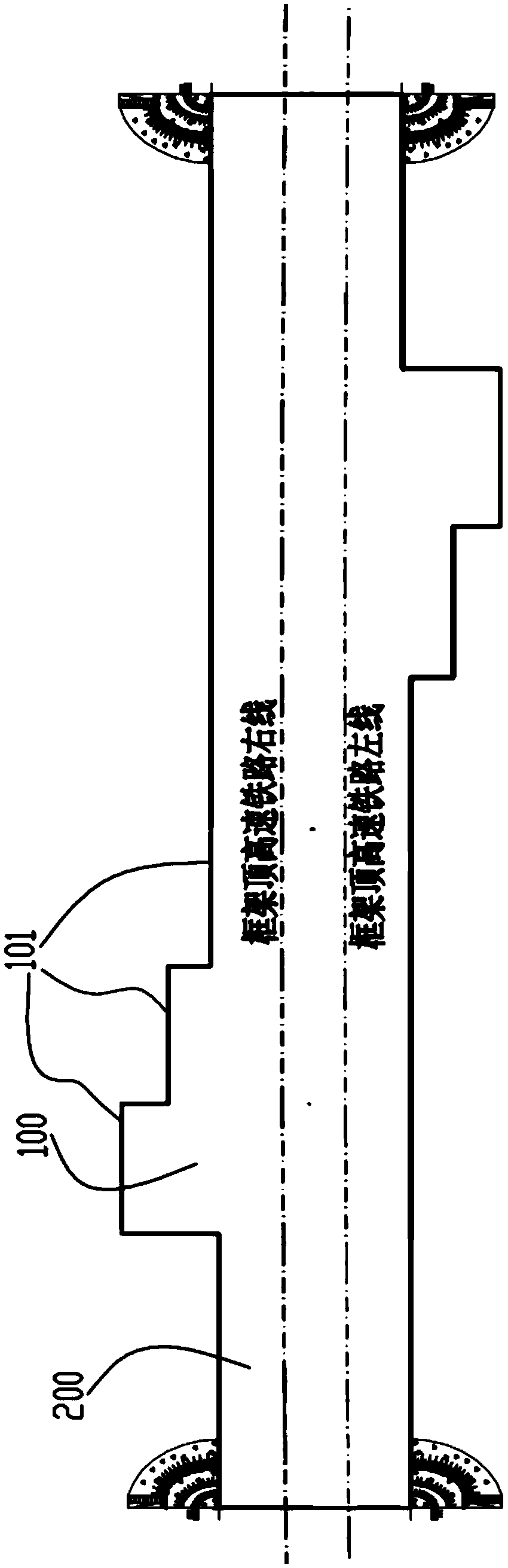

Frame bridge

PendingCN109024238AEasy to walk throughAvoid rough ridesBridge applicationsBridge structural detailsEngineeringSubgrade

The invention relates to a frame bridge, comprising a plurality of undergoing bridge segments connected in turn along the longitudinal direction of the bridge top rail line, wherein the side wall surfaces of each undergoing bridge segment are perpendicular to the transverse direction of the bridge top rail line; the side wall surfaces of the undergoing bridge segments are perpendicular to the transverse direction of the bridge top rail line. The underpass passes through the frame holes of each underpass section in turn, and at least the side walls near the inlet and outlet of the underpass arestaggered with respect to the adjacent side walls. As that wall surface of each side wall is set to be perpendicular to the transverse direction of the track line at the top of the bridge, and the side walls near the inlet and outlet of the underpass traffic lane are staggered with respect to the adjacent side walls, The utility model is convenient for passing through the traffic lane smoothly, meanwhile, the railway sleepers of the bridge top track line can be laid on the frame bridge completely, so as to avoid the situation that the two ends of the railway sleepers of the bridge top track line are respectively placed on the frame bridge and the roadbed with large rigidity difference, and the train running irregularity is avoided. Compared with the special-shaped frame bridge, the framebridge provided by the invention adopts a regular frame structure, and has the advantages of simple structure, definite stress, convenient construction, and small maintenance workload after operation.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

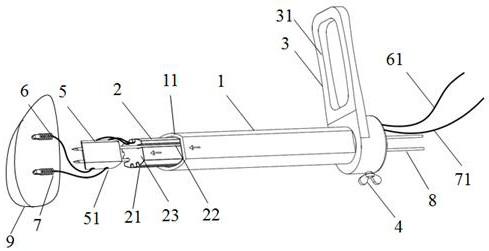

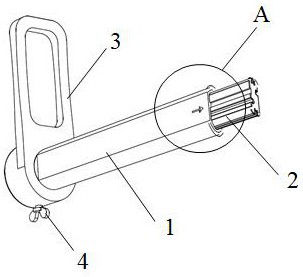

Scapular glenoid bone grafting device under minimally invasive condition

PendingCN112545629AEffective diversion exportReduce the chance of no progressBone implantJoint implantsBone graftingArthroscopy

The invention provides a scapular glenoid bone grafting device under a minimally invasive condition. The device comprises a sleeve, a threading rod and a handle, wherein the sleeve is provided with achannel; the threading rod is movably inserted into the channel in a penetrating mode; the sleeve is detachably connected with the handle; a first wedge-shaped face is arranged at one end of the sleeve; a thin groove and a wide groove are formed in the side wall of the threading rod; and a second wedge-shaped face is arranged at the end, close to a bone grafting block, of the threading rod. A method for the device comprises the following steps of S1, driving an anchor into a corresponding area under an arthroscope; S2, enabling the sleeve to be contacted and matched with the bone grafting area; S3, placing the bone grafting block into the sleeve; S4, pushing the bone grafting block into the bone grafting area; S5, fixing the bone grafting block; and S6, after the bone grafting block is fixed, removing a Kirschner wire, and suturing a wound. The bone grafting device is high in threading efficiency, high in positioning precision and capable of effectively avoiding slippage, rotation anddisplacement of the bone grafting block in the bone grafting process and reducing the damage to blood vessels, nerves and other tissues of shoulder joints due to the bad phenomenon of the bone grafting block in the bone grafting process.

Owner:XIAN HONGHUI HOSPITAL +1

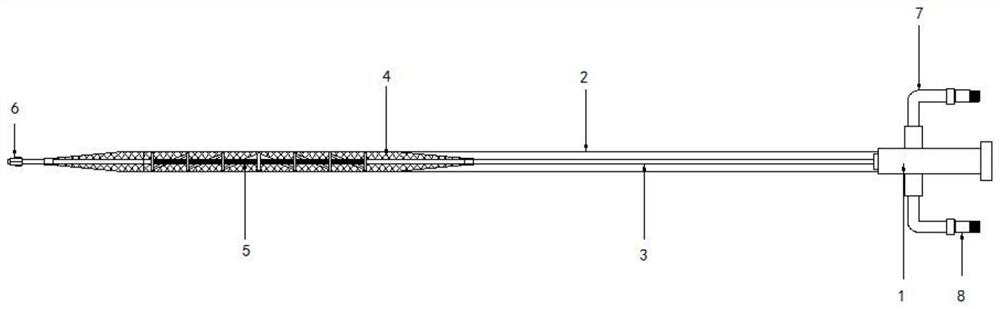

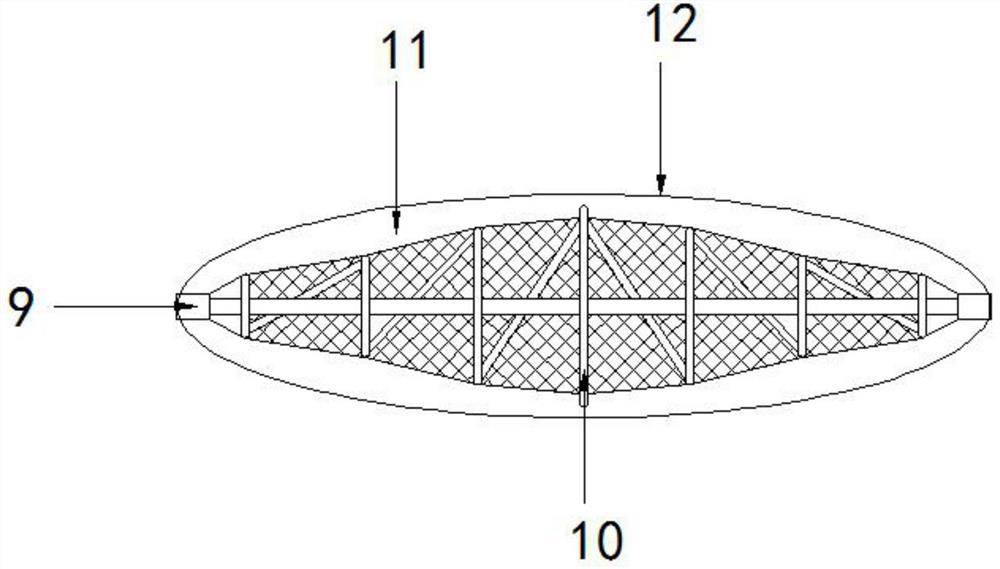

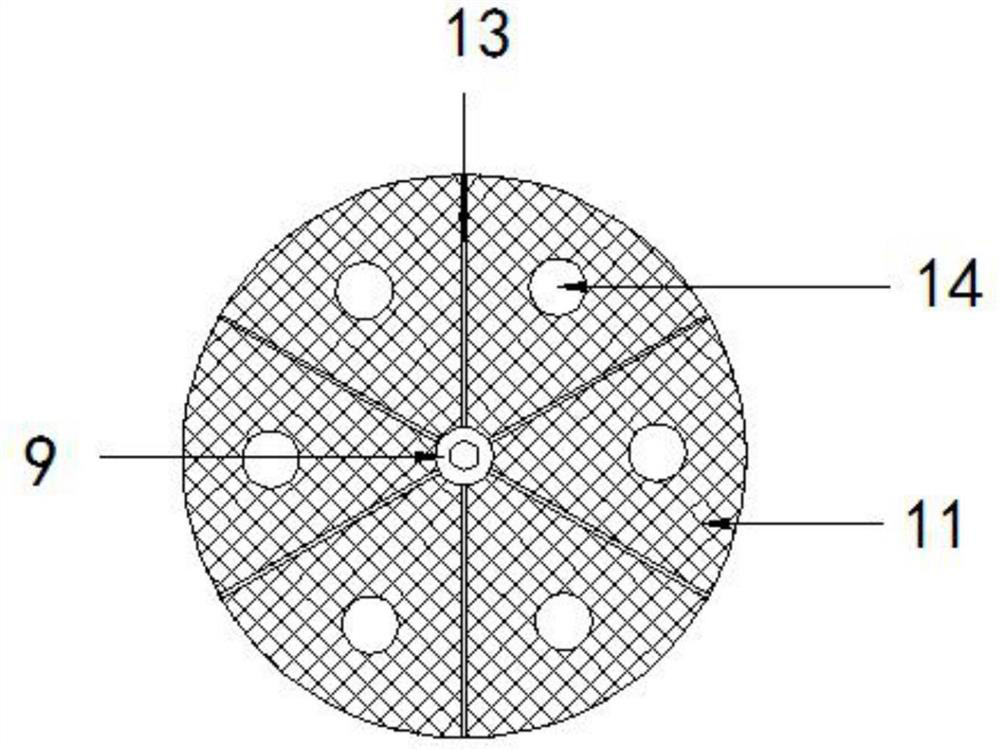

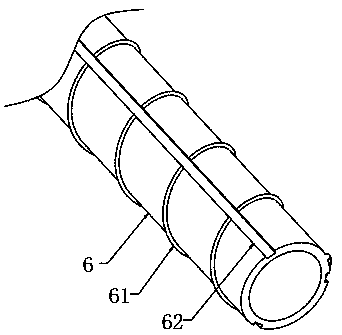

Drug coating balloon dilatation catheter for intracranial blood vessel

PendingCN114099911AAvoid damageEasy to walk throughBalloon catheterSurgeryBalloon dilatation catheterThrombus

The drug coating balloon dilatation catheter comprises a connecting tube, an outer tube is arranged on the side face of the connecting tube, an inner tube is arranged in the outer tube, a dilatation protection device is arranged on the surface of the inner tube, the dilatation protection device comprises two sets of sliding blocks, elastic rings are arranged on the inner sides of the sliding blocks, and the elastic rings are arranged on the inner sides of the sliding blocks. A blocking filter screen is arranged on the surface of the elastic ring, and a support is arranged on the inner side of the blocking filter screen. The outer pipe is arranged on the side face of the connecting pipe, the inner pipe is arranged in the outer pipe, the expansion protection device is arranged on the surface of the inner pipe, the expansion protection device comprises two sets of sliding blocks, an elastic ring is arranged between the two sets of sliding blocks, and the elastic ring is of a spring column structure and is small in two ends and large in the middle; the blocking filter screen is arranged outside the elastic ring and can block thrombus or plaque floating from the upstream during lesion treatment, and a small amount of blood is allowed to flow, so that the influence of blocking on the body is reduced.

Owner:南京脉创医疗科技有限公司

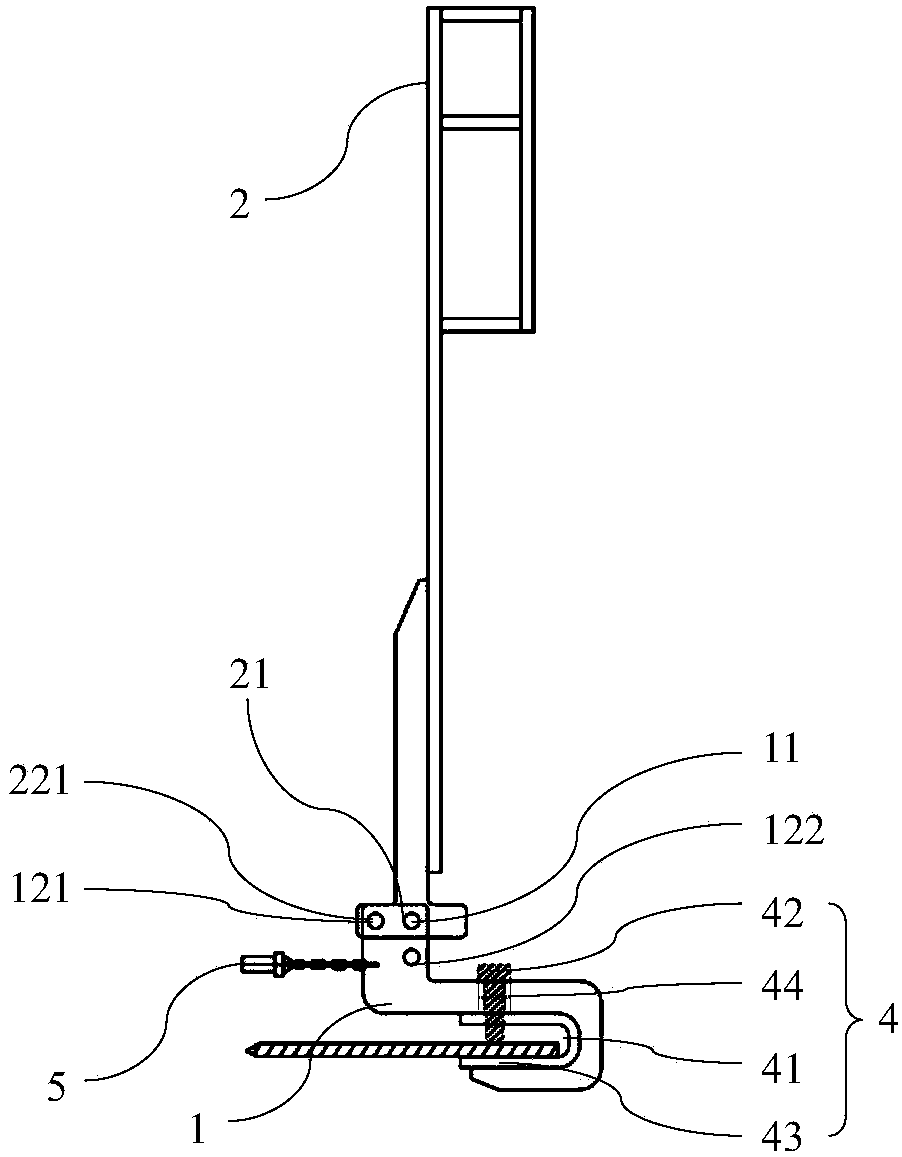

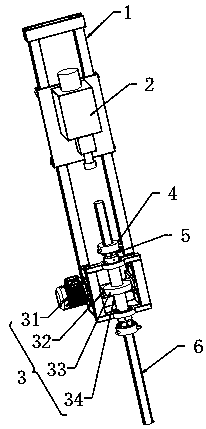

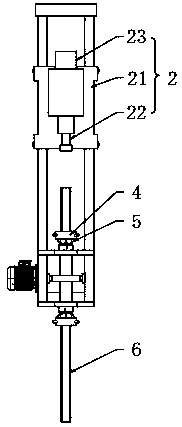

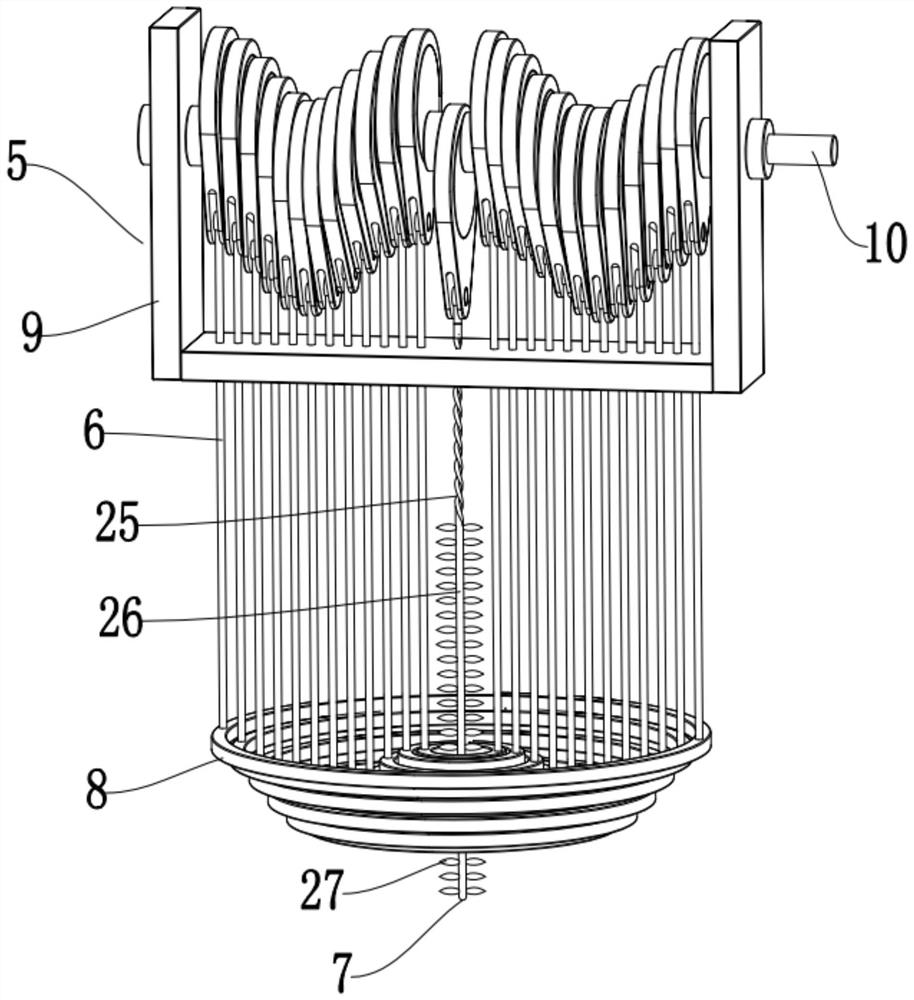

Rotary piling equipment and piling method

ActiveCN110847170AEasy to walk throughImprove pullout resistanceBulkheads/pilesElectric machineArchitectural engineering

The invention provides rotary piling equipment, which comprises a mounting frame, a piling assembly, a rotating assembly and a pile embracing clamp. The piling assembly is slidably mounted on the mounting frame and comprises a pile hammer; the rotating assembly is arranged at the bottom of the mounting frame and comprises a first motor and a rotating cylinder, the rotating cylinder is rotatably connected with the mounting frame, the two ends of the rotating cylinder are open, the rotating center of the rotating cylinder and the pile hammer are coaxially arranged, and the first motor is in transmission connection with the rotating cylinder; the pile embracing clamp is fixedly connected with the rotating cylinder, and the embracing center of the pile embracing clamp and the rotating cylinderare coaxially arranged; and a spiral bulge is arranged on the peripheral face of a construction pile. Thus, the construction pile during rotating obtains impact force so as to achieve the effect of rotating impact for combined feed, through the spiral bulge arranged on the periphery of the construction pile, the construction pile is stably connected with surrounding soil during rotating feed, thus pulling resistance of the construction pile is enhanced, the construction process of pouring cement mortar is omitted, and the construction cycle is shortened.

Owner:CHONGQING HONGGONG INSTRUCTIONAL MACHINE

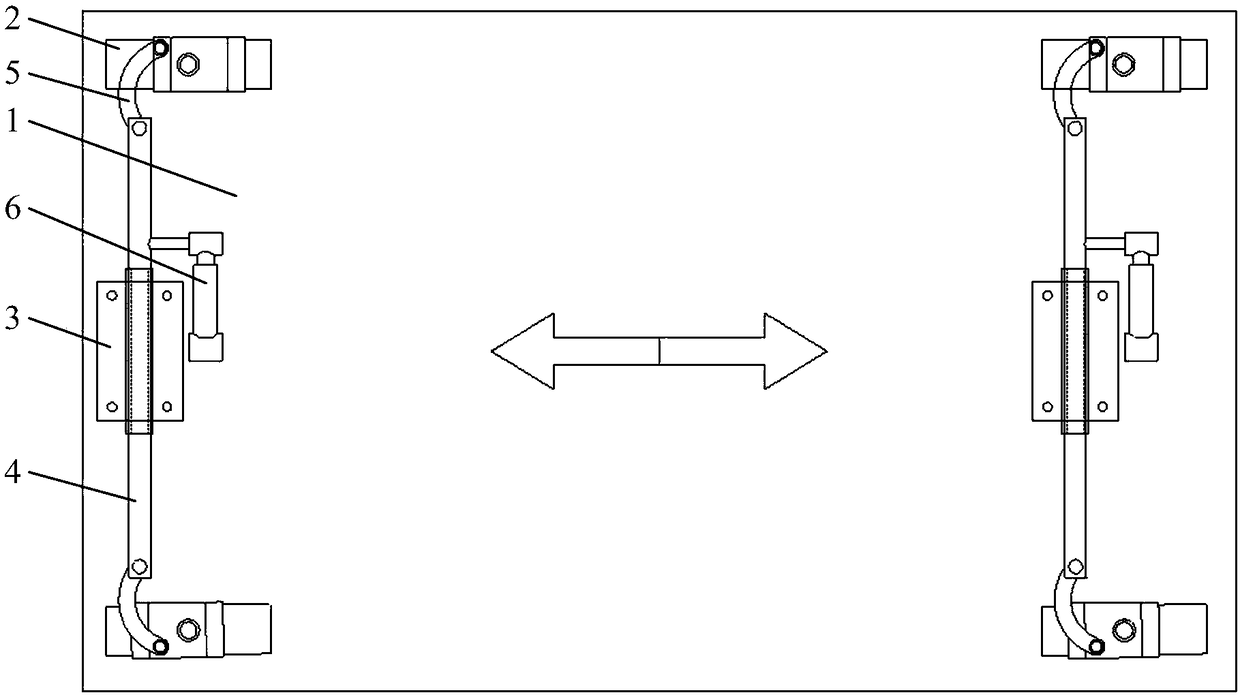

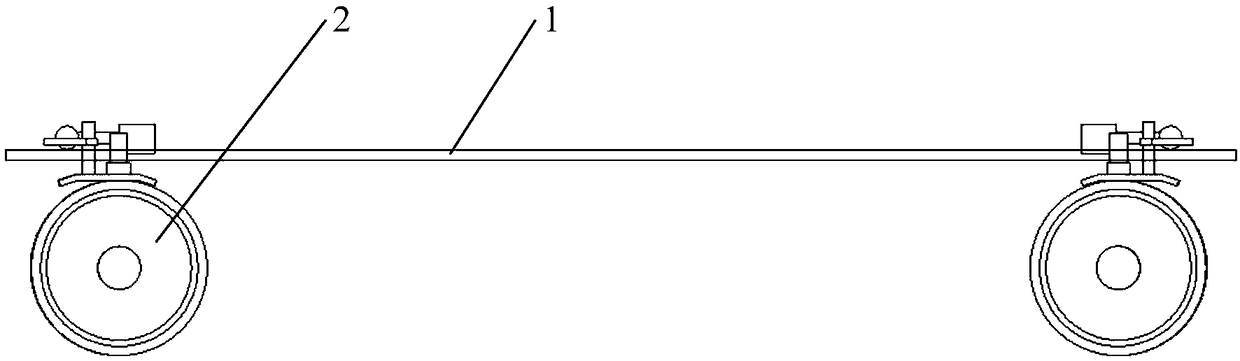

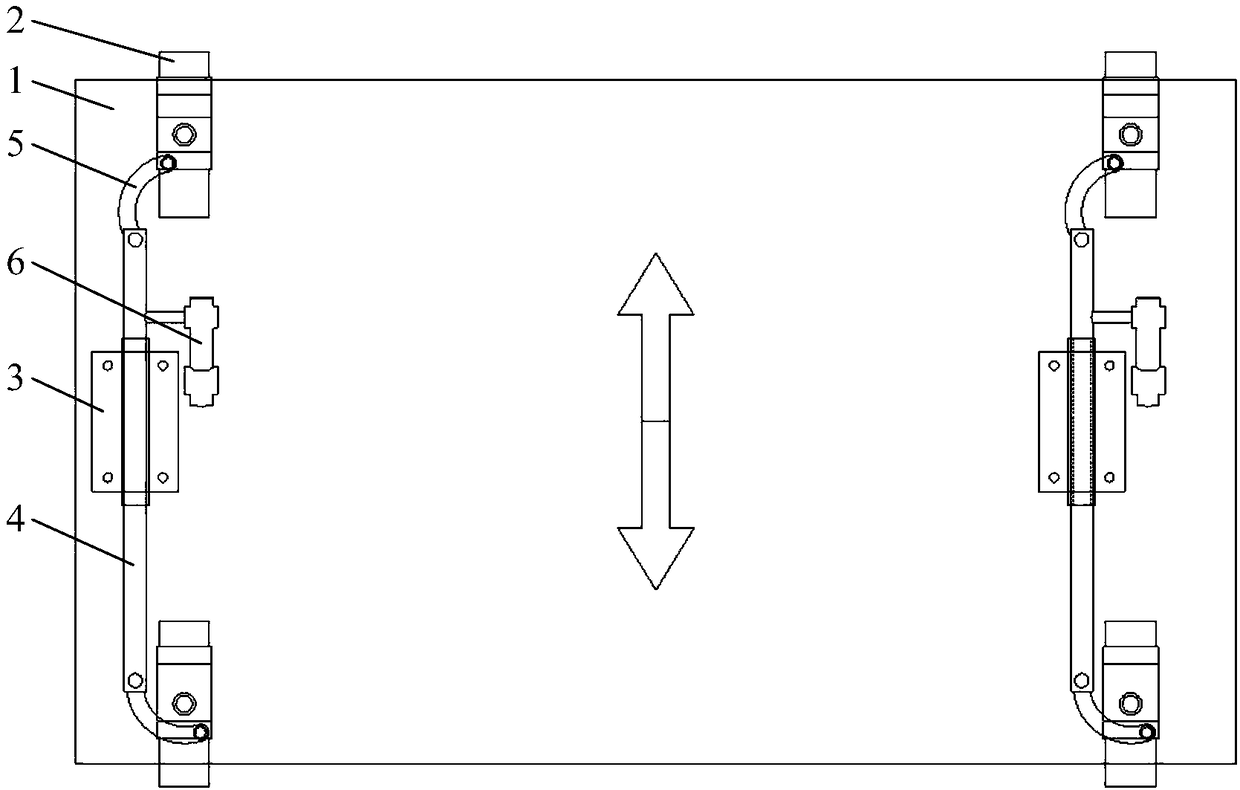

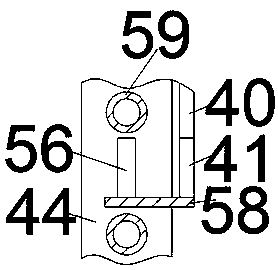

Cable guide mechanism

ActiveCN104112548AStable supportGuaranteed reliabilityInsulating conductors/cablesEngineeringMechanical engineering

Owner:广州凯栎自动化设备有限公司

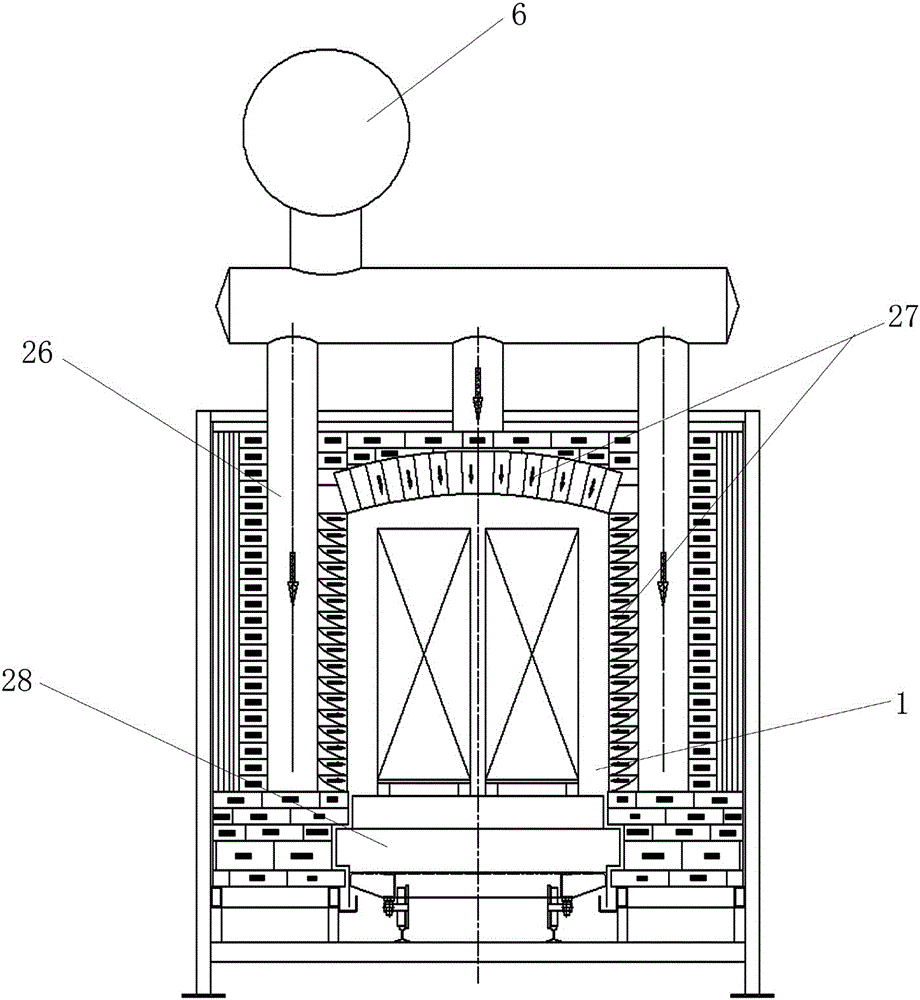

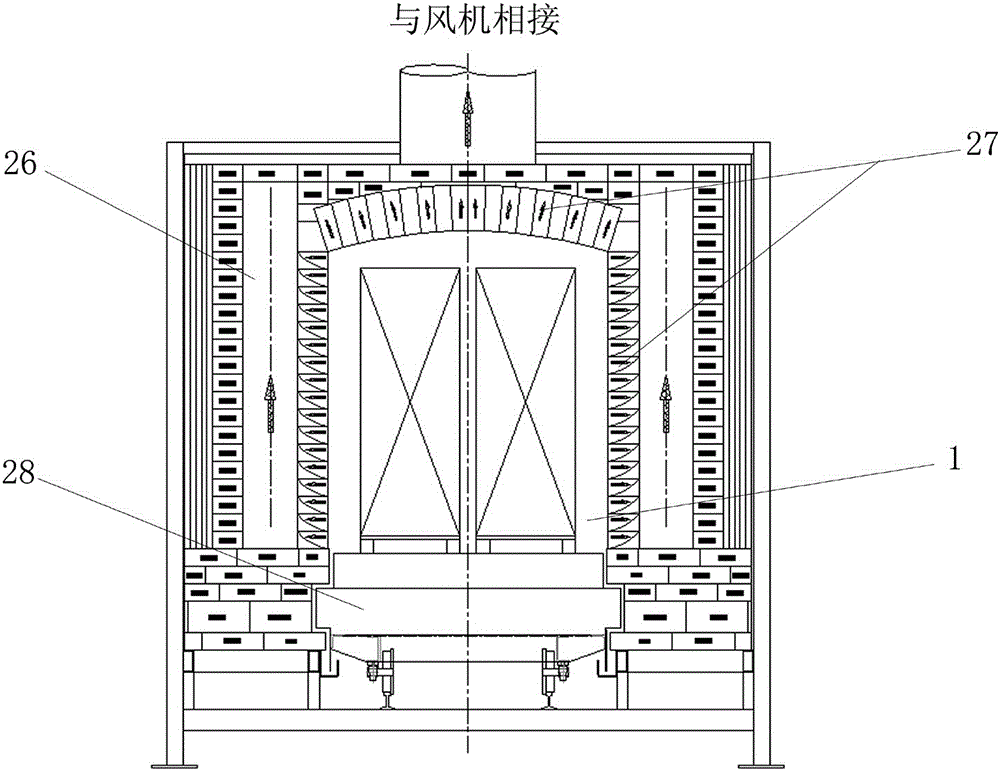

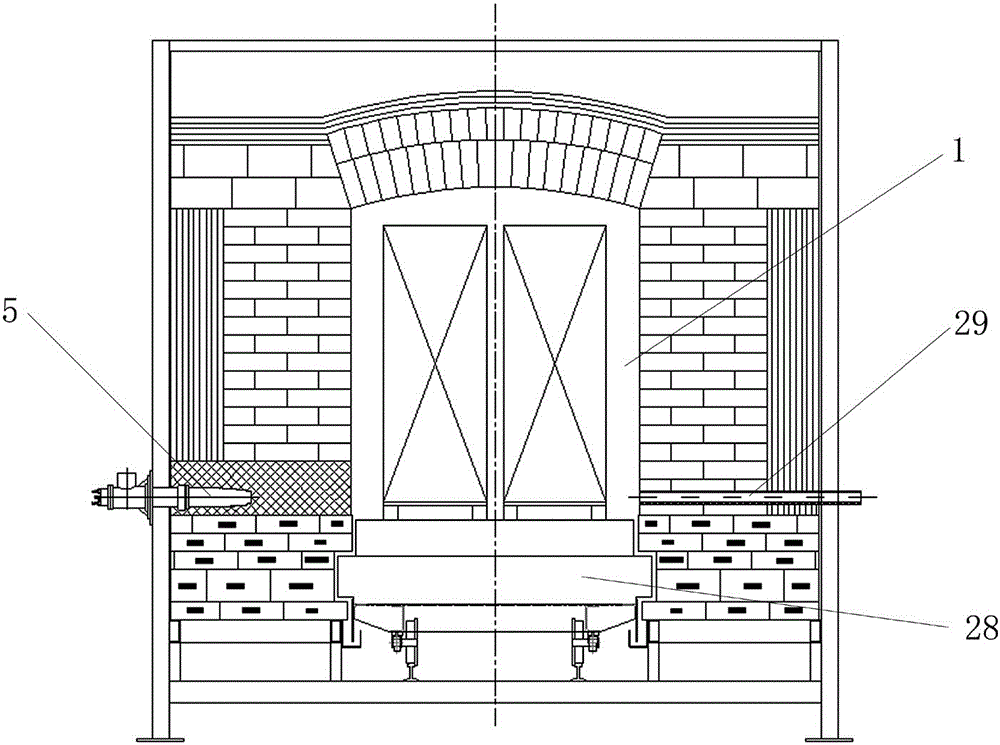

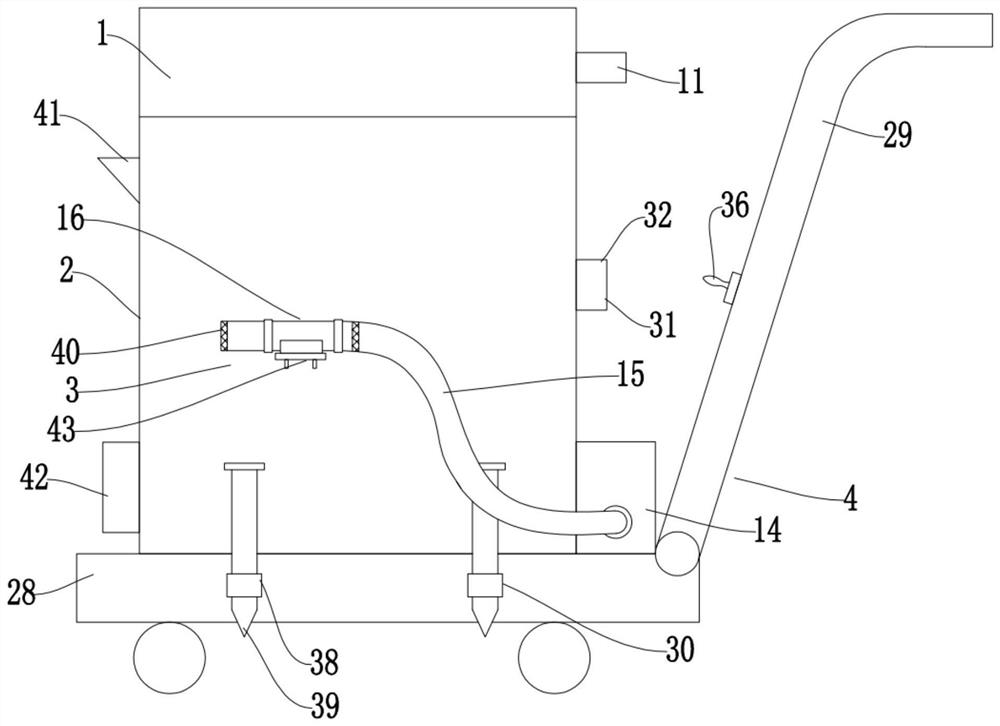

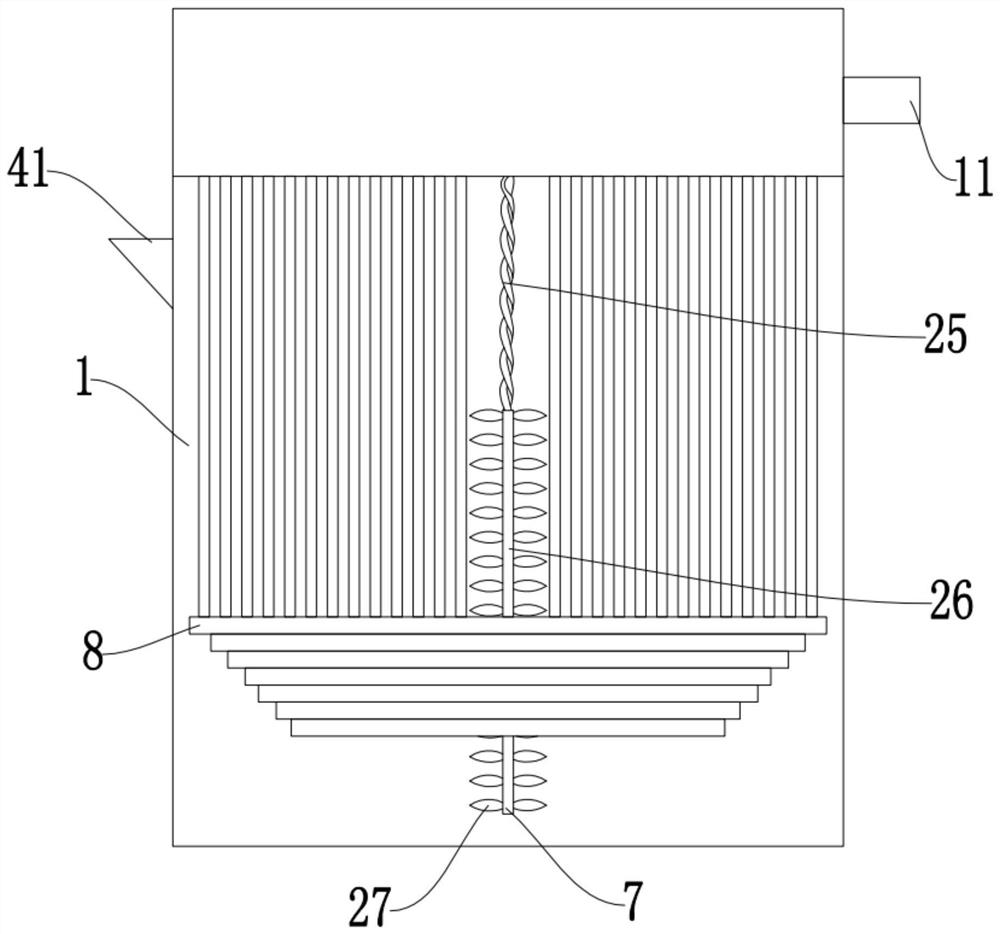

Energy-saving and emission-reduction tunnel kiln suitable for firing of ceramic products

InactiveCN106338201AUniform and stable temperatureEnergy-saving optimization effect is obviousFurnace typesCeramic materials productionTunnel kilnCombustion system

The invention relates to an energy-saving and emission-reduction tunnel kiln suitable for firing of ceramic products. The energy-saving and emission-reduction tunnel kiln suitable for firing of the ceramic products comprises a kiln body channel, a draught fan system and a combustion system. A kiln body is arranged in the kiln channel. The kiln channel is provided with an oxidation evaporation section, a strong oxidation section, a strong reduction section, a firing section, a heat preservation section and a cooling section. The draught fan system is composed of an inlet smoke exhaust draught fan, an air curtain conversion draught fan, a chilling draught fan, a heat extraction draught fan, a combustion-supporting draught fan, a kiln tail air supply draught fan, air channels and a vent duct. Each air channel comprises a cavity layer arranged on the wall of the kiln body, and the cavity layers communicate with air outlets formed in the wall of the kiln body and in a vault of the kiln body. The combustion system is composed of a gas inlet pipe and flame guns. The combustion-supporting draught fan provides combustion-supporting air to the flame guns. The energy-saving and emission-reduction tunnel kiln suitable for firing of the ceramic products has a high energy utilization rate and the remarkable technological advantages of energy saving and emission reduction and achieves the effect that the overall energy can be saved by 30%; and the temperature in a high-temperature area is stable and uniform, and therefore firing of the products is facilitated.

Owner:广东明宇科技股份有限公司

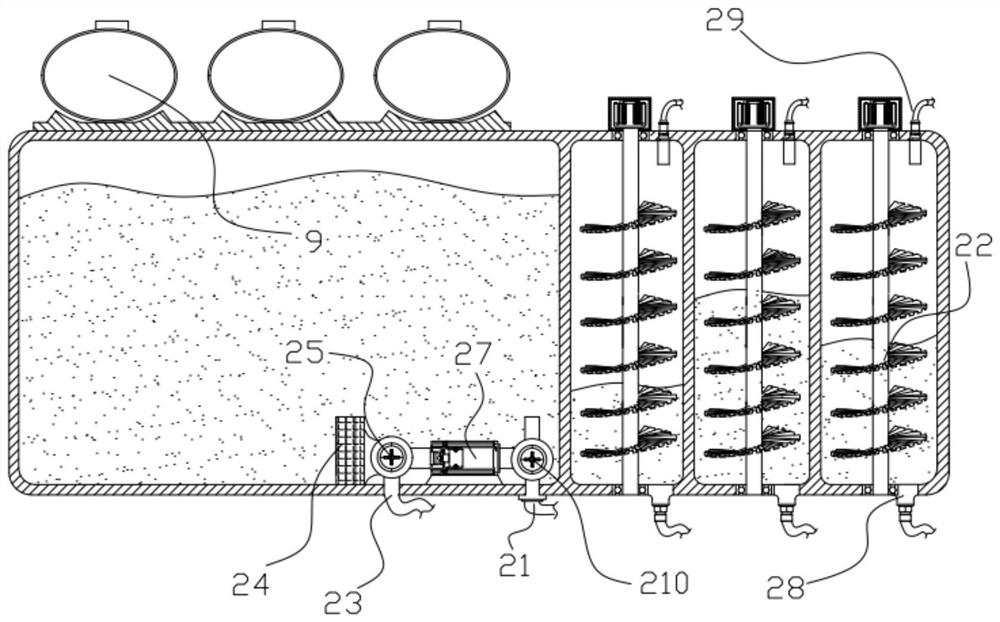

Water conservancy conveying equipment for farm irrigation

PendingCN111903479AIncrease the degree of mixingImprove mixing uniformityManure treatmentShaking/oscillating/vibrating mixersWeedCart

The invention discloses water conservancy conveying equipment for farmland irrigation. The equipment comprises a pesticide longitudinal and transverse mixing anti-blocking integrated device, a pesticide mixing treatment box, an anti-blocking water source extraction device and a folding type movable fixed cart, the pesticide mixing treatment box is arranged on the folding type movable fixed cart. The pesticide longitudinal and transverse mixing anti-blocking integrated device is arranged in the pesticide mixing treatment box, and the anti-blocking water source extraction device is arranged on the folding type movable fixed cart and is connected with the pesticide mixing treatment box. The invention belongs to the technical field of farmland irrigation, and particularly relates to the waterconservancy conveying equipment for the farmland irrigation. The equipment covers the whole transverse plane space and longitudinally moves in an independent staggered manner, so that water is comprehensively mixed, the lifting and rotating effects are overlaid, the mixing degree of pesticides is further increased, the mixing uniformity of the pesticides is better facilitated, weeds and the like in a water source can be prevented from being crushed to cause blockage, the occupied space of the whole equipment is reduced, and the stability, the firmness and the safety are enhanced through the braking performance.

Owner:JIANGSU XIMEI IRRIGATION & DRAINAGE EQUIP CO LTD

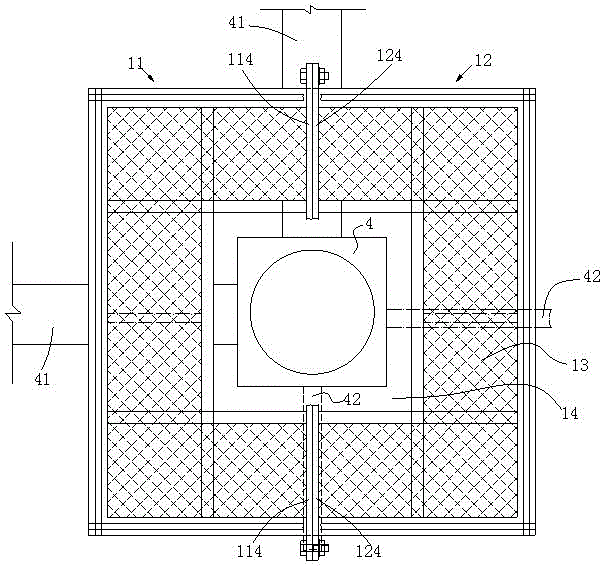

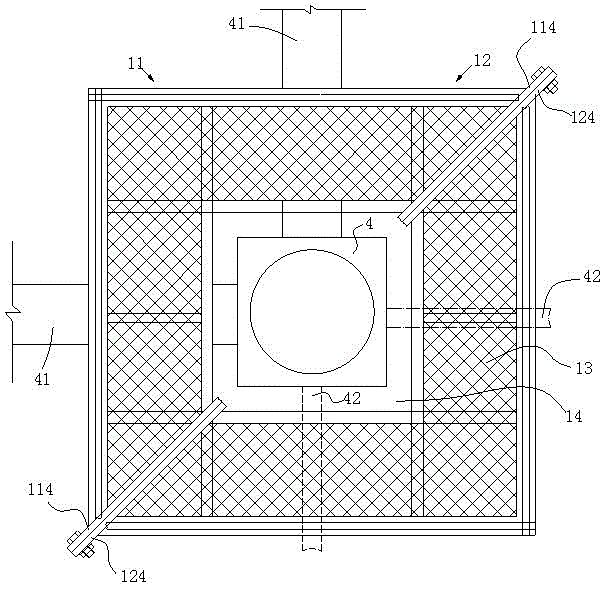

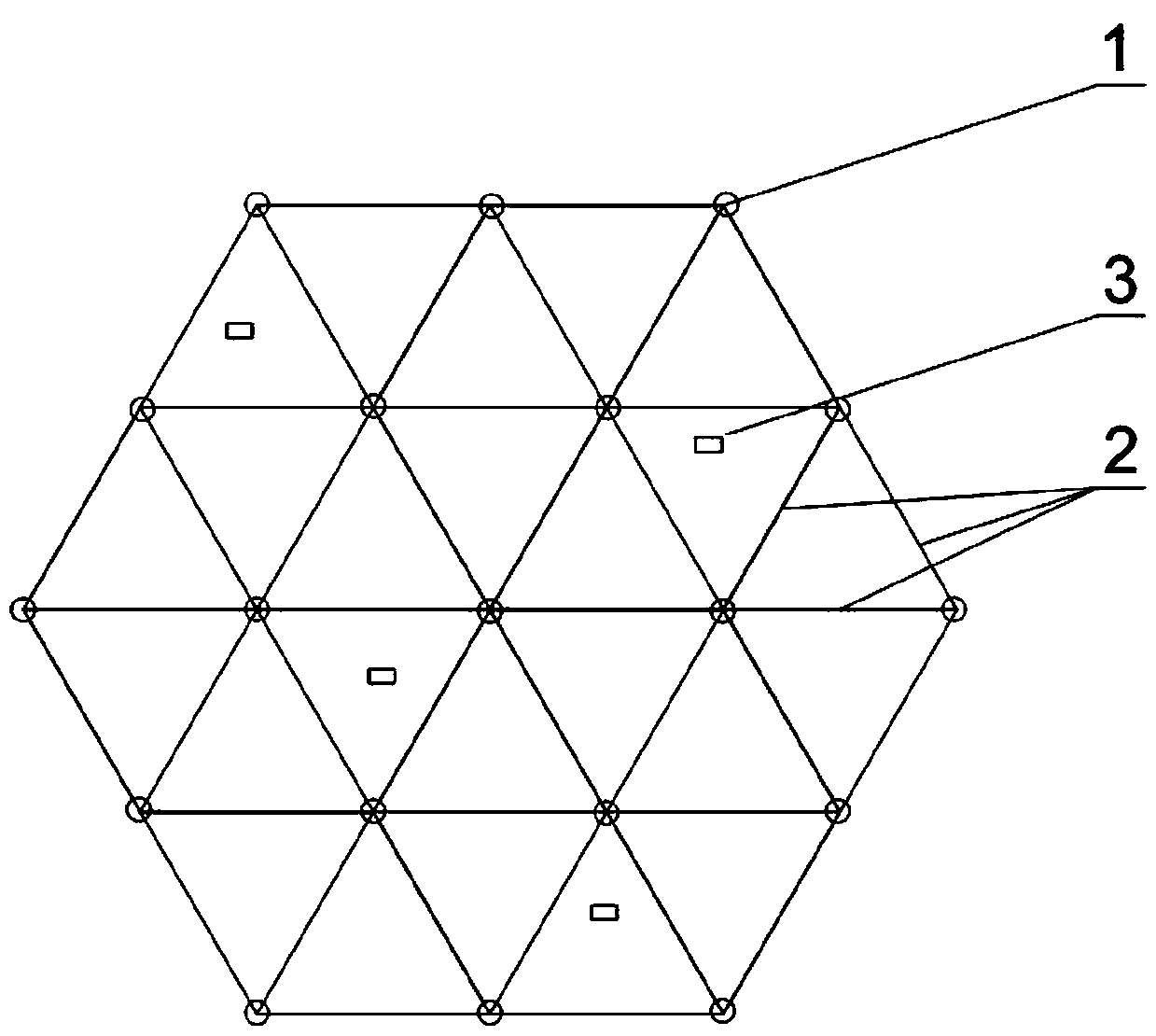

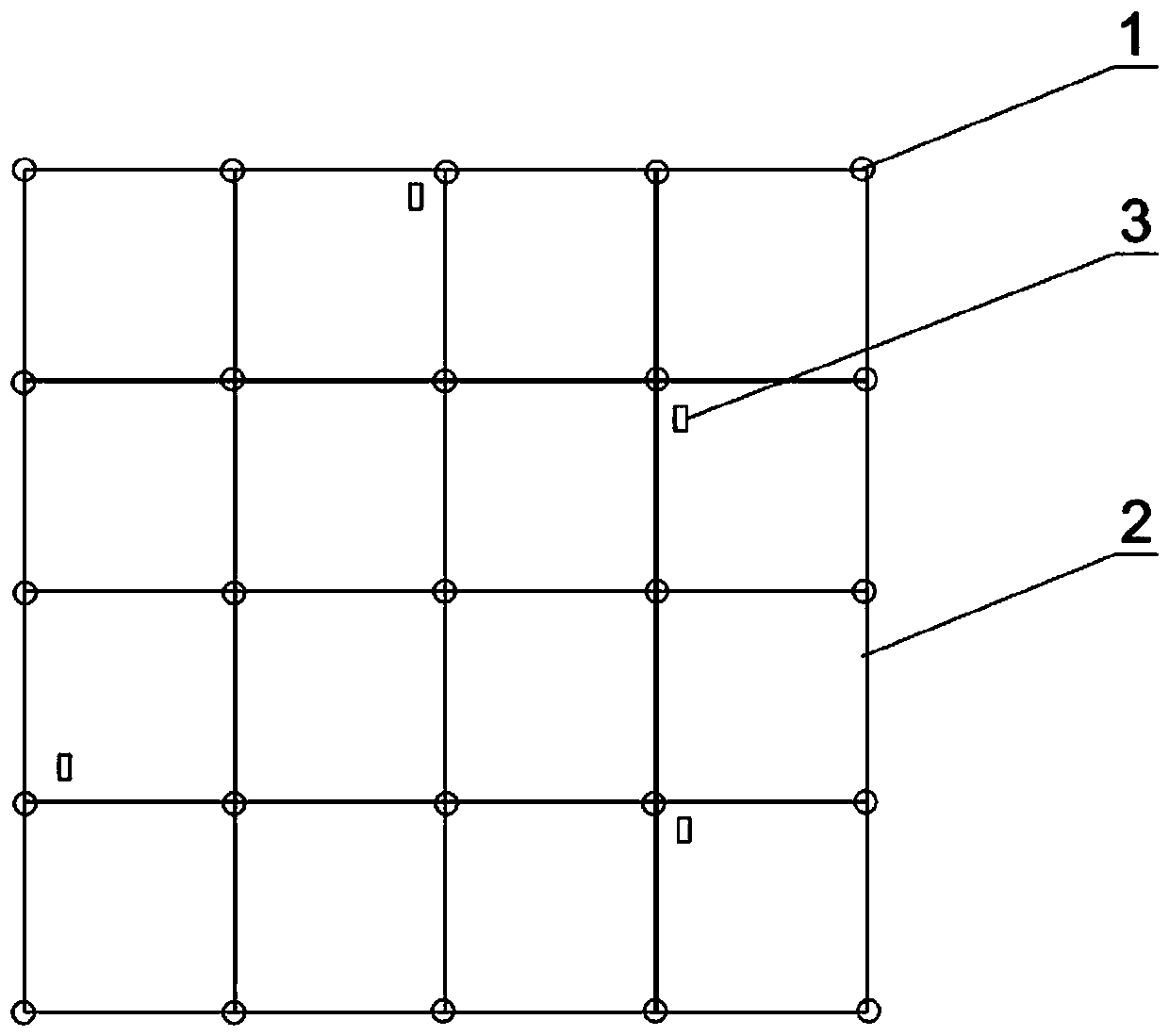

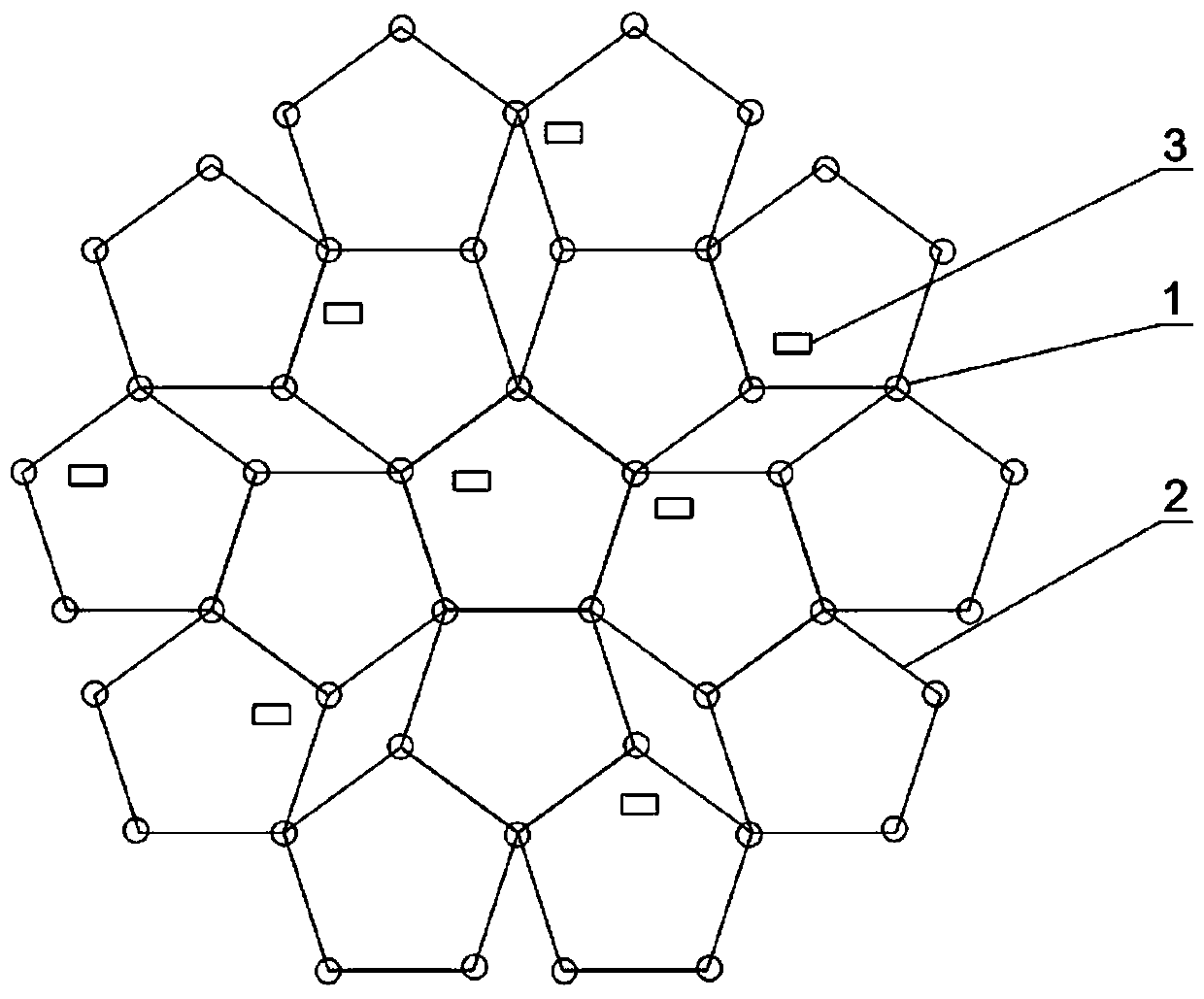

Three-dimensional maze for macaque monkeys

ActiveCN110583511AQuick buildEasy to cleanClimate change adaptationTaming and training devicesResearch efficiencyEngineering

The invention belongs to the field of animal experiment equipment, and particularly relates to a three-dimensional maze for macaque monkeys. The three-dimensional maze for the macaque monkeys is composed of a plurality of maze units in a vertical or horizontal direction or a comprehensive array of both the vertical and horizontal directions; the maze units are composed of a plurality of positioning columns, top columns, automatic doors and feeding boxes, the automatic doors are arranged between adjacent positioning columns and are arranged on the top surfaces defined by the top columns, each automatic door is provided with a shuttle door for the macaque monkeys to pass through, each shuttle door is provided with an automatic opening and closing door cover, and a customized maze can be formed by opening and closing the automatic opening and closing door cover on the automatic door. During use of the three-dimensional maze for the macaque monkeys, by opening and closing the automatic opening and closing door covers on the automatic doors between adjacent positioning columns, the three-dimensional maze of which the internal structure is changed according to the research needs can be quickly established, the maze pattern can be changed as required by simply controlling the opening and closing of rolling doors and disassembly and installation work is avoided, thus the time and effort are saved and the research efficiency is improved.

Owner:KUNMING INST OF ZOOLOGY CHINESE ACAD OF SCI

Temporary bridging device with adjusting function for municipal traffic ditch

InactiveCN111778870AGuaranteed stabilityEasy to walk throughBridge erection/assemblyWinding mechanismsButt jointArchitectural engineering

The invention discloses a temporary bridging device with an adjusting function for a municipal traffic ditch, and relates to the technical field of municipal traffic. The temporary bridging device forthe municipal traffic ditch comprises two trapezoidal plates, the opposite surfaces of the two trapezoidal plates are fixedly connected with supporting plates, rectangular grooves are formed in the supporting plates, and fixing frames are fixedly connected in the rectangular grooves. According to the temporary bridging device with the adjusting function for the municipal traffic ditch, two clamping blocks are respectively clamped into the two clamping grooves through the extension of two electric push rods II; under the combined action of the electric push rods II, a clamping block, a clamping groove, a hinge seat III and a pin shaft III, the principle that a triangle has stability is utilized, and butt joint plates are lifted and supported; the stability of the butt joint plates in the using process is further guaranteed; the two butt joint plates are connected together to support each other; the stability of the device in the using process is further guaranteed; and the device is ingenious in structure, reasonable in design, convenient to use and convenient for a user to use.

Owner:吴万荣

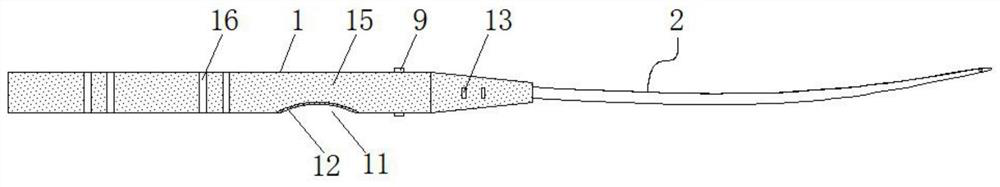

Special guide needle for under-eye puffiness

PendingCN112263292AMeet the needs of flexible length changesReduce rigiditySuture equipmentsPuffiness around the eyesBiomedical engineering

The invention discloses a special guide needle for under-eye puffiness. The special guide needle comprises a handle and a guide needle body, wherein the guide needle body is arranged at one end of thehandle; the guide needle body comprises a straight needle part, a curved needle part and a needle head; a bevel edge is arranged on the needle head; a needle thread hole is formed in the needle head;a through groove is formed in the end, close to the straight needle part, of the handle; an adjusting nut is arranged at the end, away from the curved needle part, of the straight needle part; a guide block is arranged on the outer wall of one end of the handle; and a thread guide hole is formed in the guide block. The guide needle body is set to be composed of the straight needle part, the curved needle part and the needle head; the curved needle part has relatively small rigidity compared with a traditional round hole straight needle, so that threading operation can be conveniently carriedout in a relatively small operation environment; the straight needle part is matched with the adjusting nut and the through groove, so that the installation length of the guide needle body in the handle can be adjusted, and the requirement for flexible change of the length of the guide needle in an operation can be met; and the thread guide hole is formed, so that an operation thread can be guided, and the phenomenon that the operation thread is wound is avoided.

Owner:深圳壹号美都医疗美容门诊部

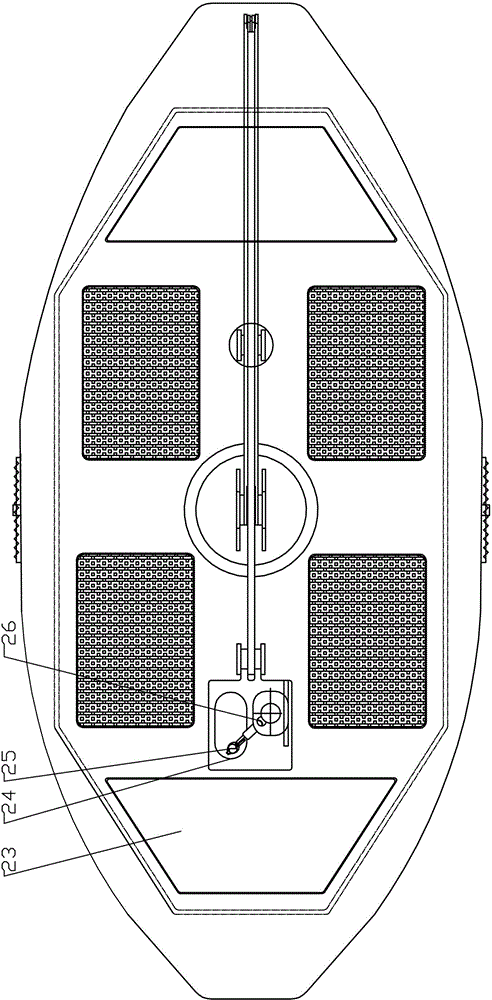

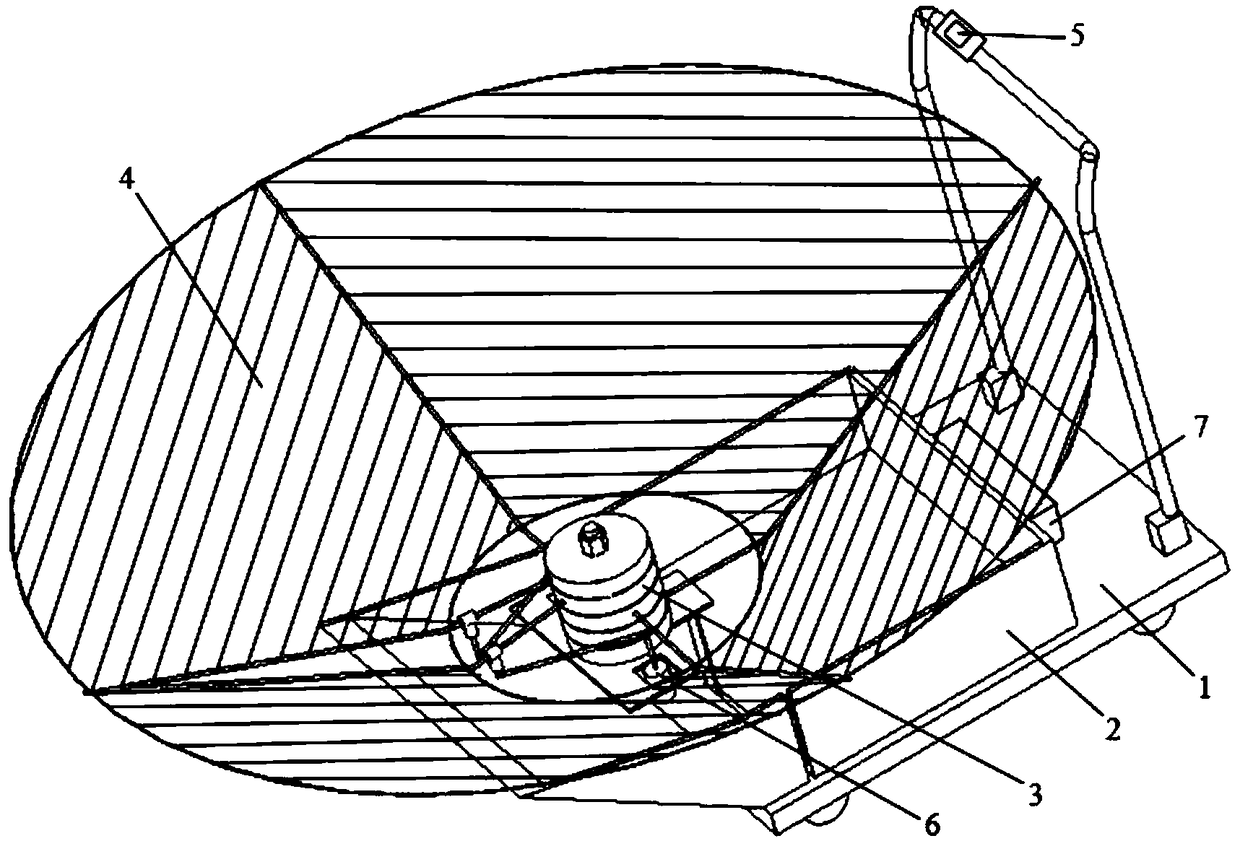

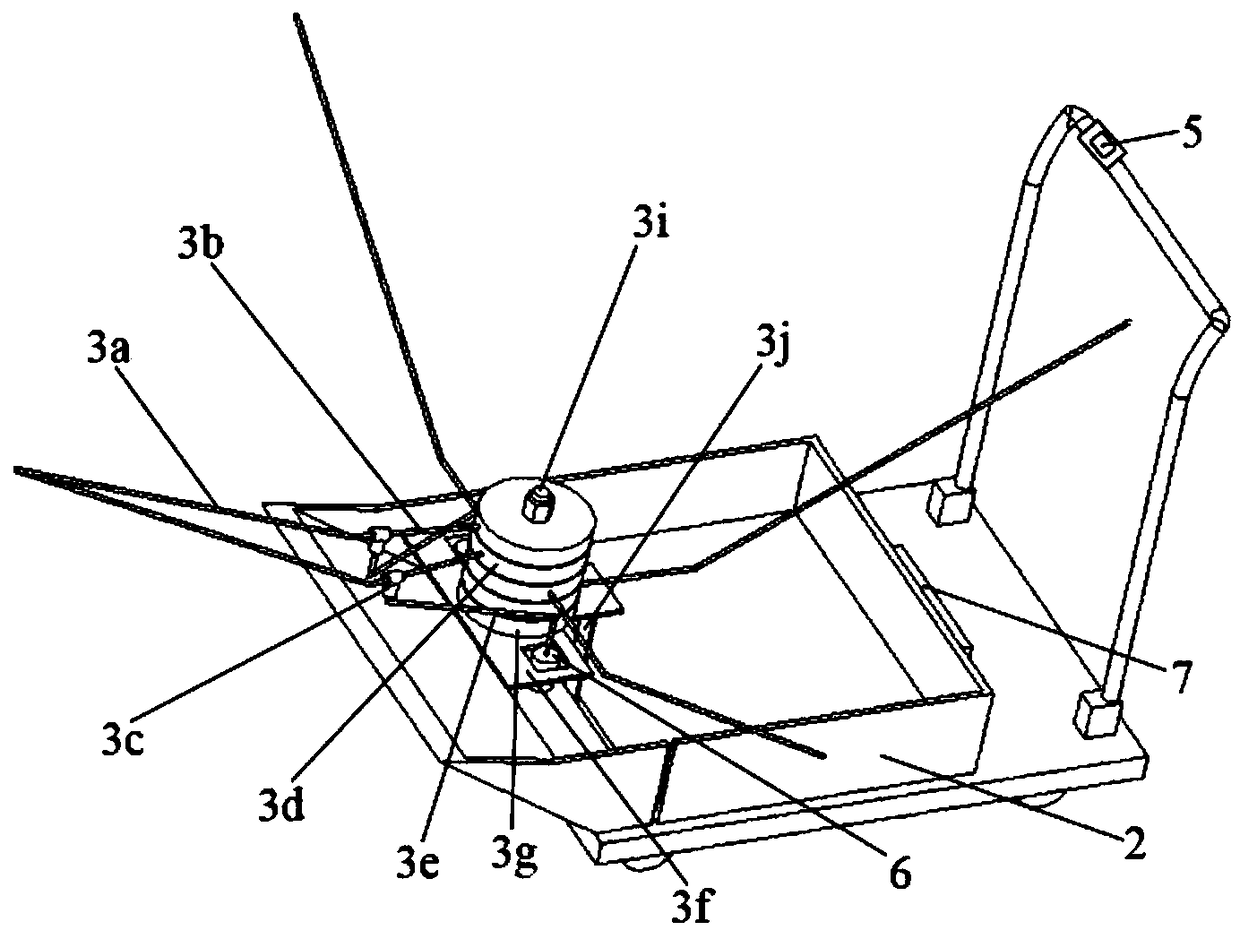

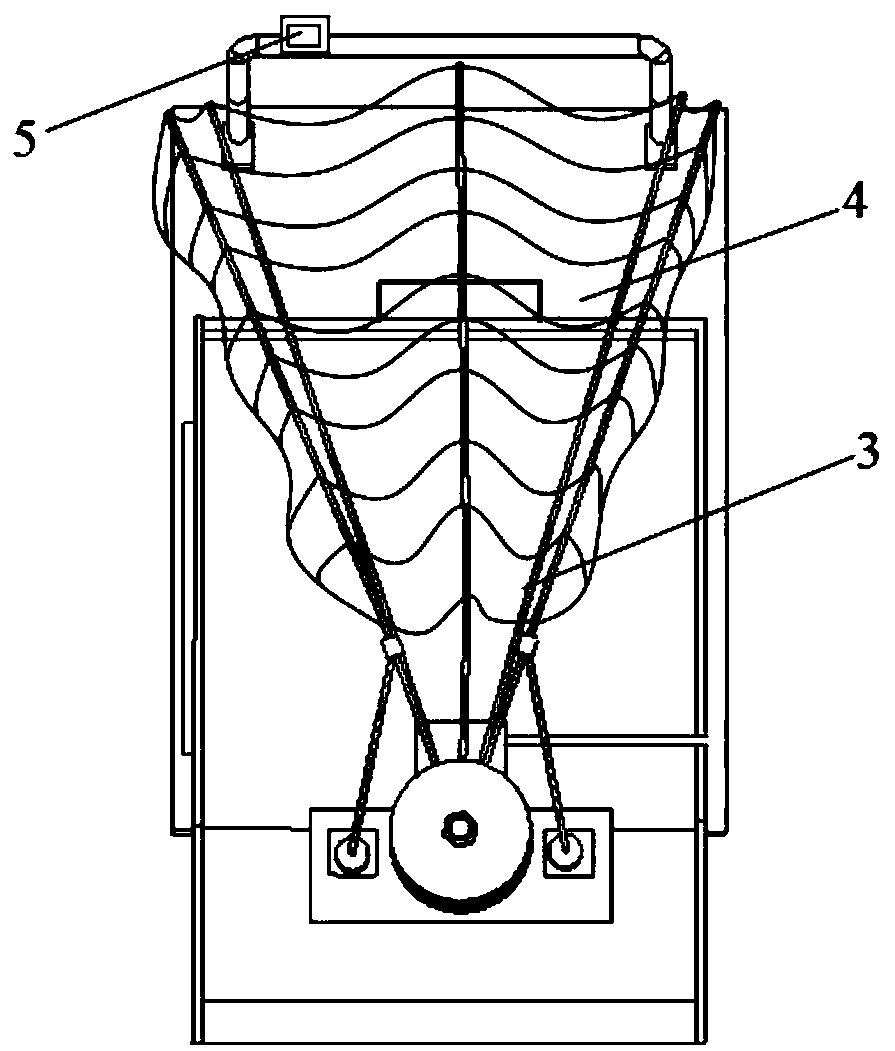

Electric forest fruit collecting device

The invention discloses an electric forest fruit collecting device. The electric forest fruit collecting device comprises a moving chassis (1), a detachable fruit collecting box (2) is detachably installed on the moving chassis (1), and a mesh cloth collecting mechanism is installed above the detachable fruit collecting box (2); the mesh cloth collecting mechanism comprises an elastic mesh cloth (4) and a spatial linkage mechanism (3), the spatial linkage mechanism (3) is used for fixing the elastic mesh cloth (4) and driving the elastic mesh cloth (4) to be unfolded and folded, and the spatial linkage mechanism (3) is driven by a direct-current motor and controlled by a control switch (5). Through the control switch, the spatial linkage mechanism drives the elastic mesh cloth to be unfolded and folded, and forest fruits are efficiently and nondestructively collected into the detachable fruit collecting box; when the elastic mesh cloth is folded, the collecting device is small in sizeand can pass through a fruit forest conveniently. The collecting device is flexible in overall structure, easy to install and convenient to move and meets the requirements for high efficiency and practicality.

Owner:ANHUI AGRICULTURAL UNIVERSITY

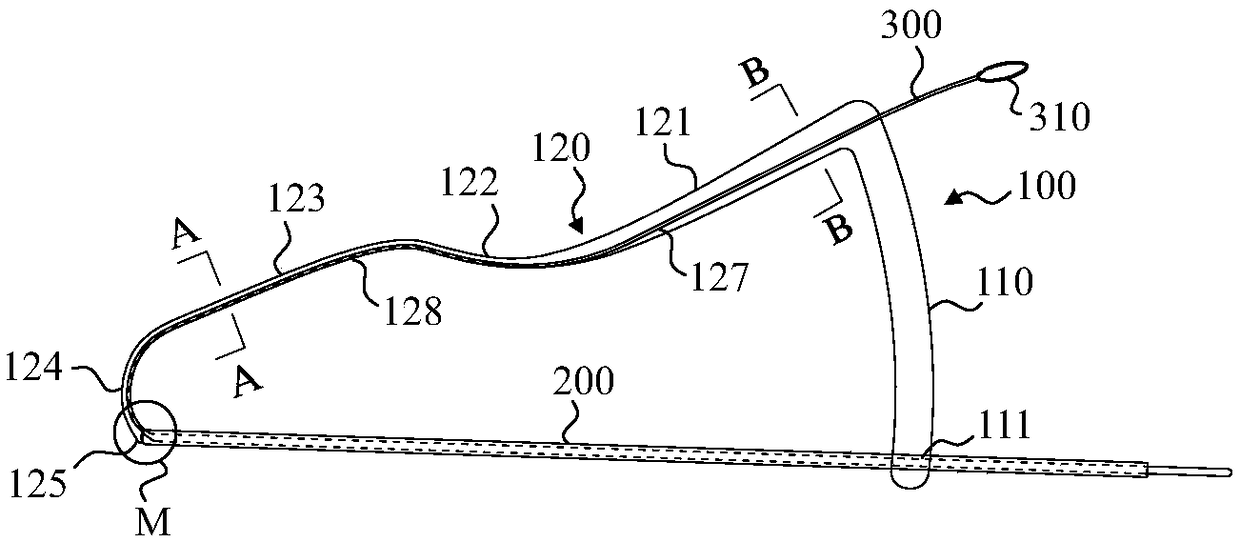

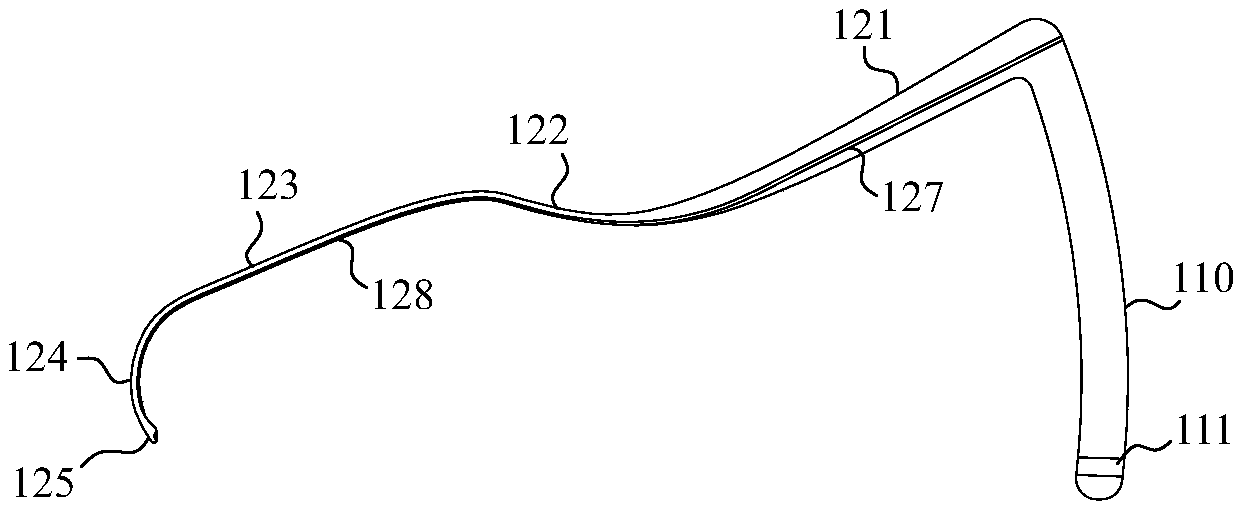

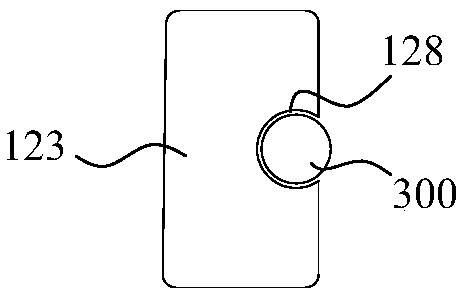

Stripping guiding device for orthopedic surgery

ActiveCN109009334AAvoid damageReduce thicknessInternal osteosythesisEndoscopic cutting instrumentsStress pointEngineering

The invention discloses a stripping guiding device for an orthopedic surgery. The device comprises a handle, a guiding rod and a guiding wire; the handle comprises a wide handle part, a guiding part and a bending part, and the guiding part is provided with a penetrating hole and / or a penetrating groove used for the guiding wire to penetrate from the wide handle part out of a free end; a blunt endis arranged at the front end of the guiding rod and is in threaded connection with the free end of the guiding part; the handle is provided with a guiding groove used for the guiding rod to penetratethrough and cooperative with a fixed groove. The device is applicable to the stripping of muscle tissue, nerve and blood vessels and the penetrating and guiding of the guiding wire and a lead line tobundle or fix bone blocks and ligaments. The bending part of the device can effectively prevent that in the stripping process, the muscle tissue is injured, the thickness of the handle is reduced as far as possible on the basis of ensuring the guiding wire to normally penetrate, and especially the guiding groove formed in the inner surface of the handle has the reinforcing rib effect to improve the strength of a stress point of the handle.

Owner:李莉

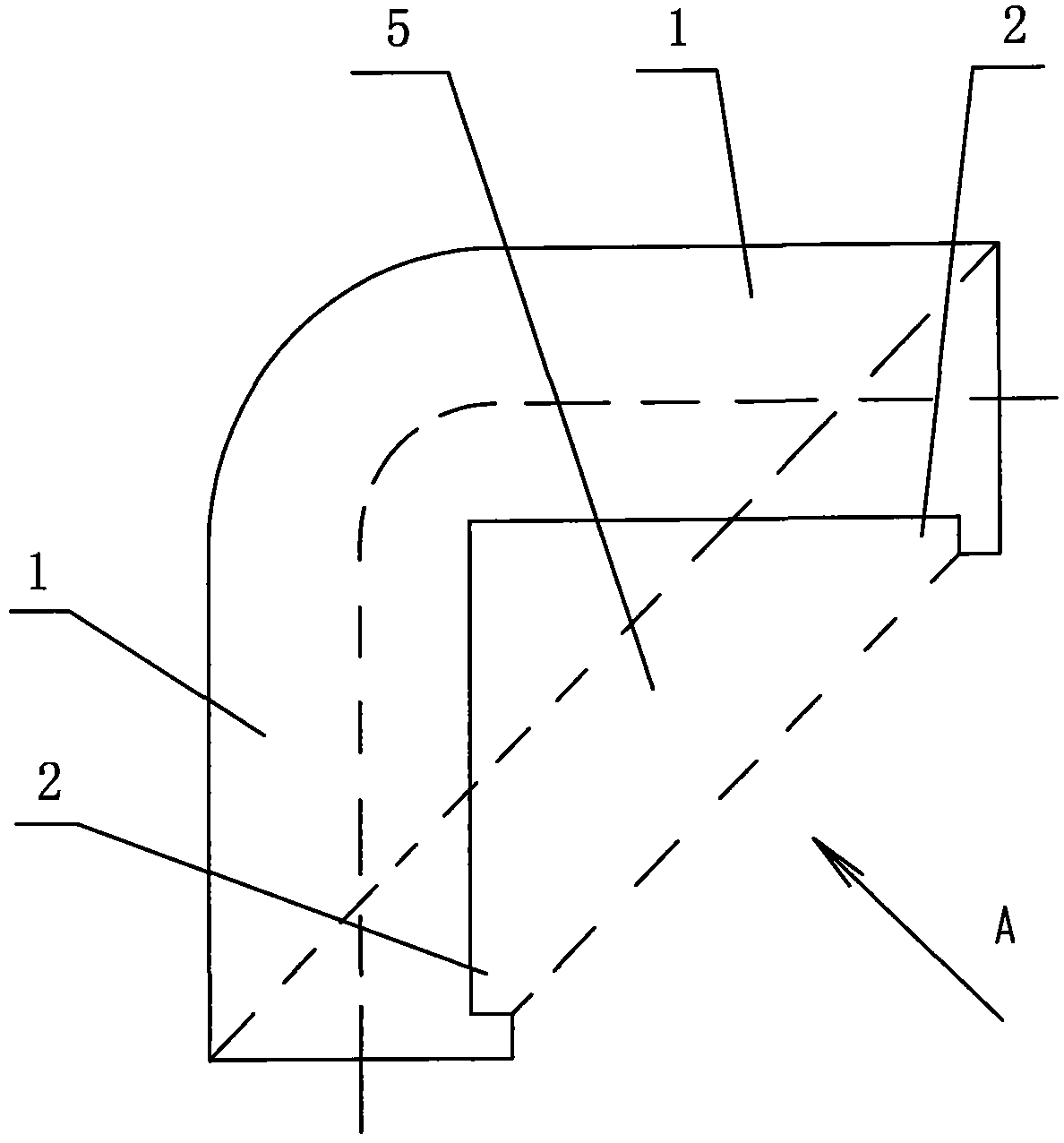

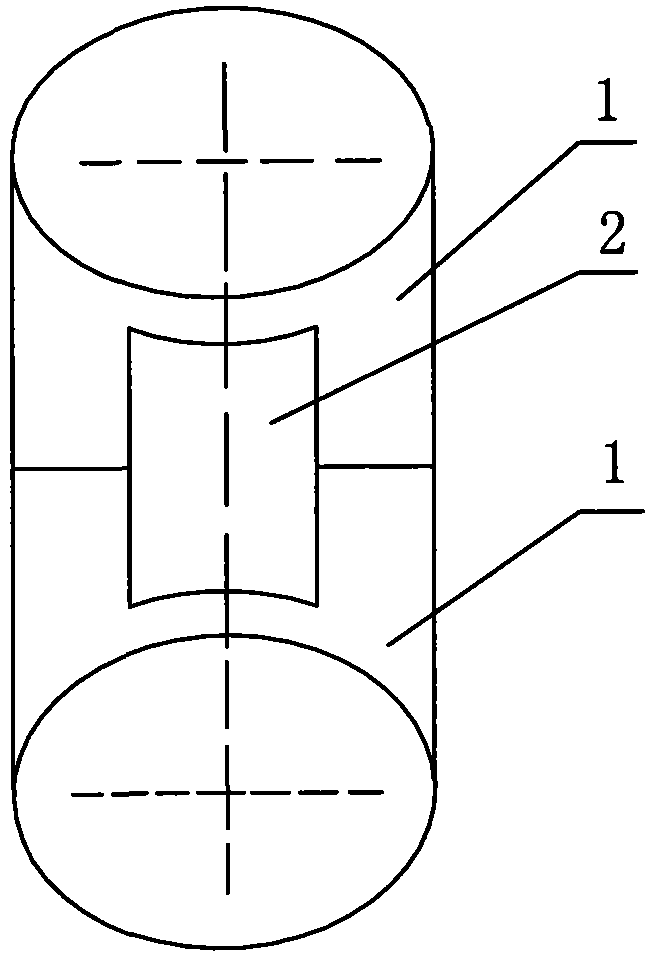

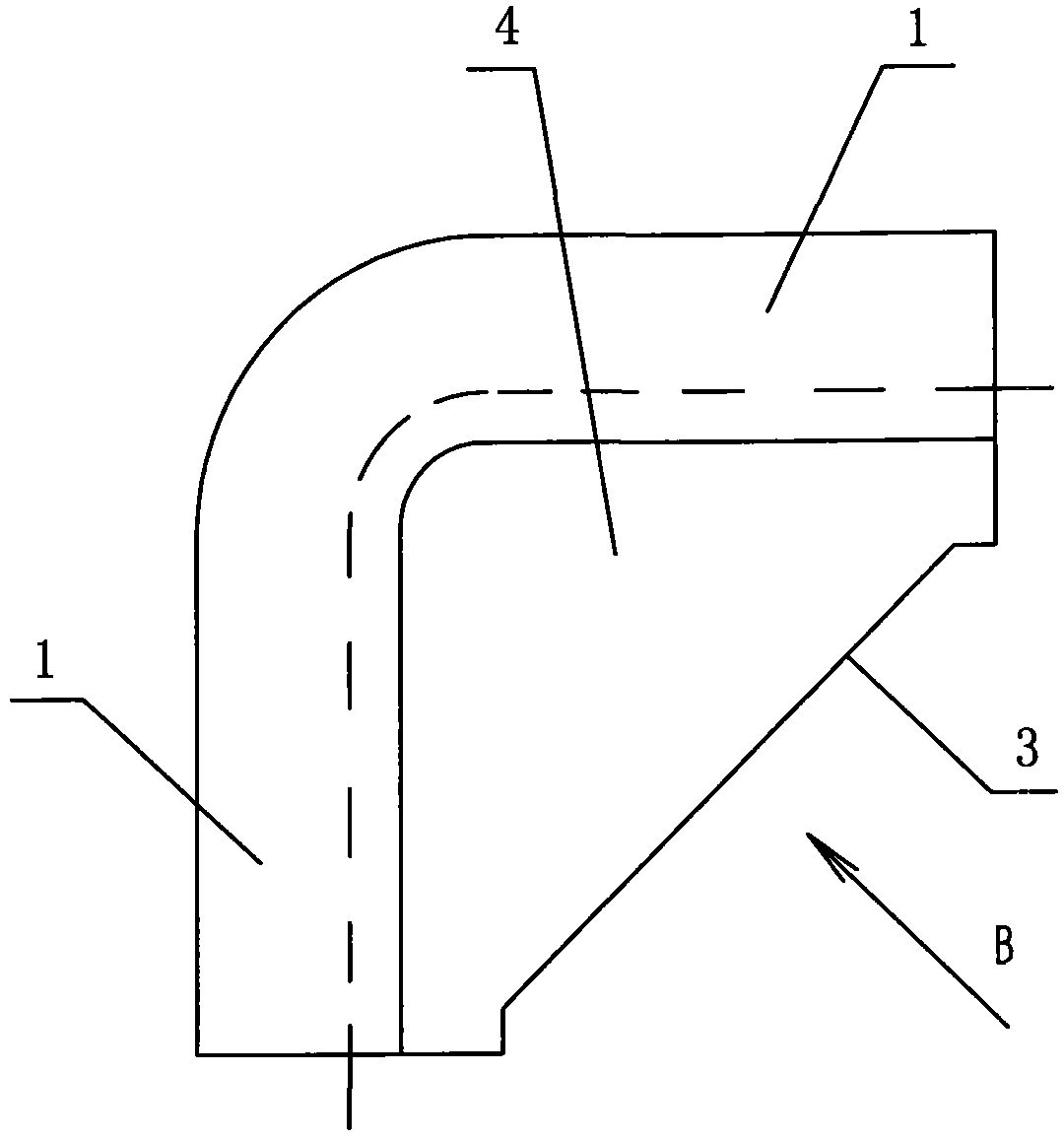

Elbow for various pipelines

InactiveCN104344140AShorten the pathEasy to walk throughBranching pipesSiphonsStraight tubePulp and paper industry

The invention discloses an elbow for various pipelines. The exterior angle of the through portion of semi-circumferences on the outer sides of two through straight tubes is in arc transition, the interior angle of the through portion of the inner sides of the two straight tubes is 90 degrees, an axial notch is formed in the center of each of the semi-circumferences of the inner sides of the two straight tubes, the inner ends of the two notches are communicated, the outer ends of the two notches are arranged at tube openings of the corresponding straight tubes, each end of each notch is not exposed out of the circumferential end of the inner side of the corresponding straight tube, and accordingly, an open or sealed straight channel between the tube openings of the two straight tubes is formed. The invention further discloses another elbow for various pipelines. The two straight tubes are communicated through a small-radian bent tube. The open or sealed straight channel is formed between the two straight tubes, so that the distance of the route that an object passes through the straight tubes is reduced, obstacles at the interior angle of the straight tubes are avoided, and the object can pass through the straight tubes conveniently. The bending radian of the elbow is lowered, liquid can pass more smoothly, and the pipelines are prevented from being blocked.

Owner:甘国强

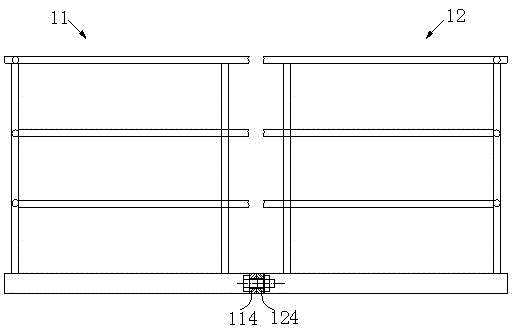

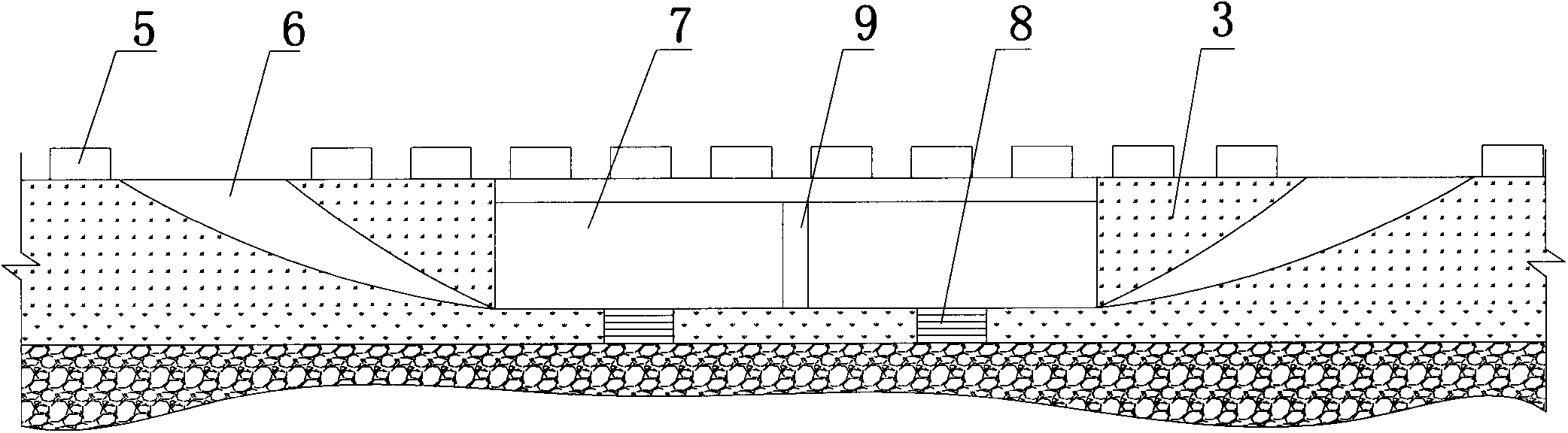

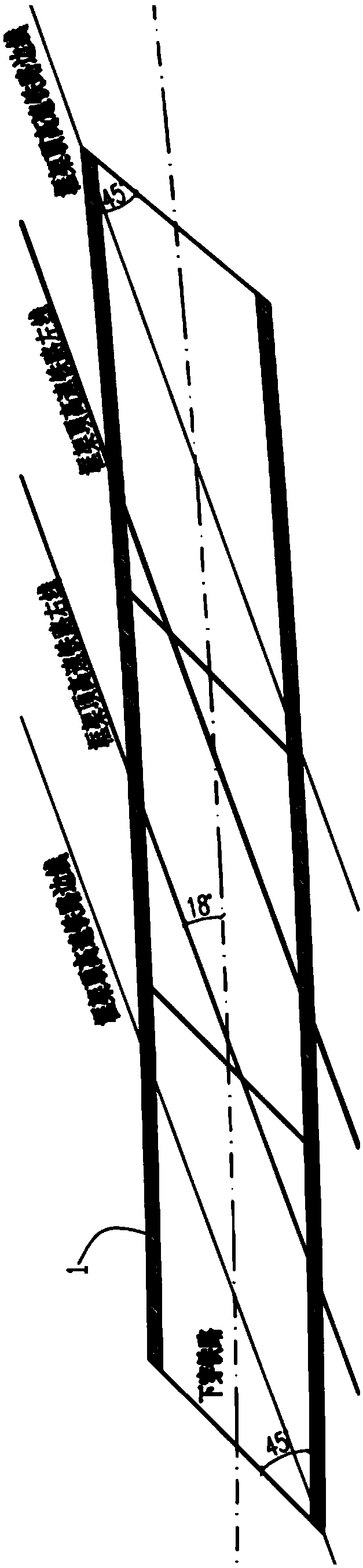

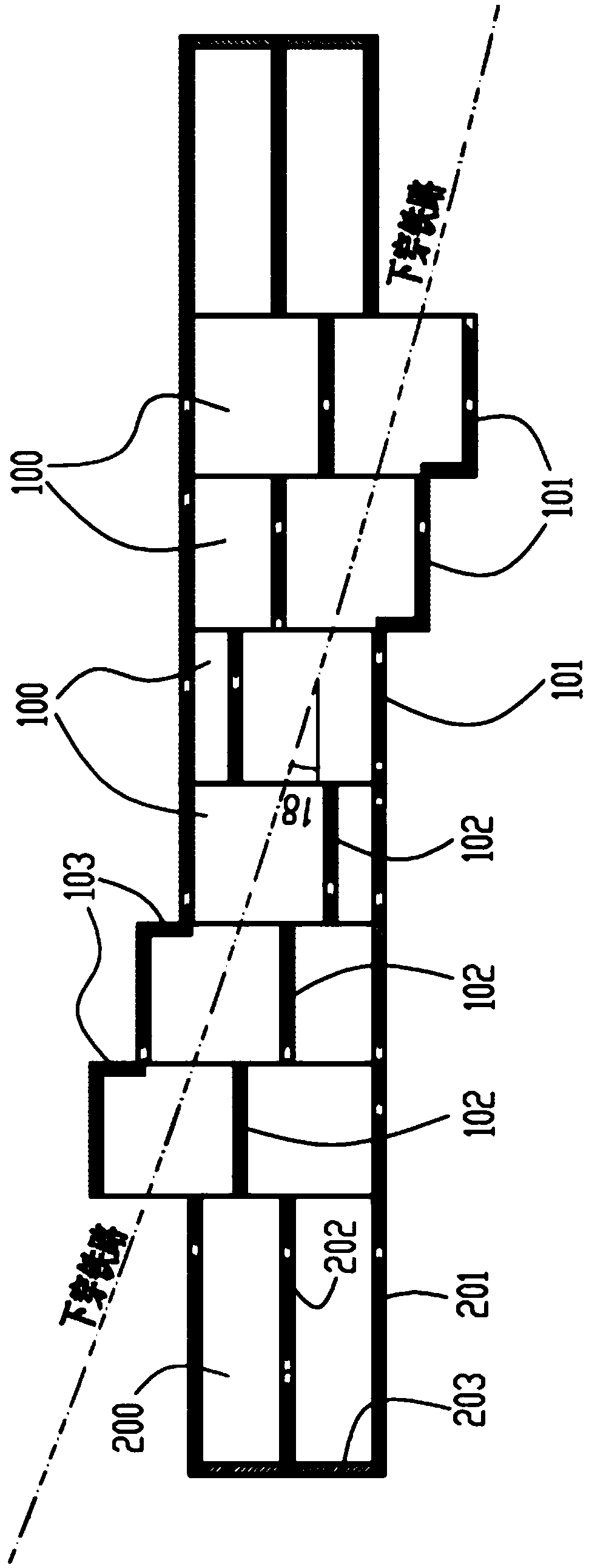

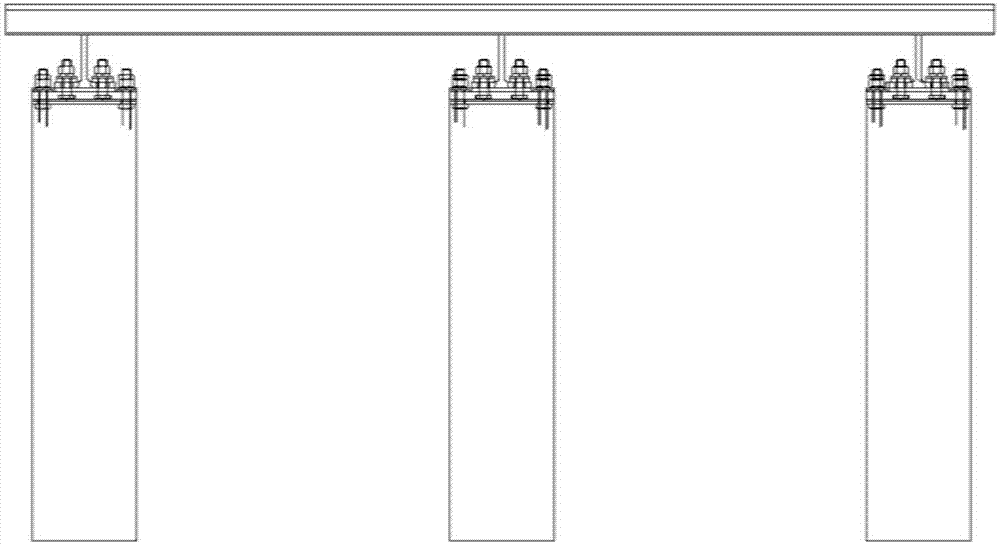

A discrete column type track bridge system for maintenance in the maglev train depot

The invention discloses a discrete type column type rail bridge system for the intra-garage overhaul of a maglev train. The rail bridge system comprises multiple rail bridge units of the same structure. The rail bridge units are arranged at intervals in the running direction of the maglev train and the interval distance s is larger than or equal to 0.5 m and smaller than or equal to 1.4 m. Each single rail bridge unit comprises a steel rail sleeper, two F-type steel rails and two supporting columns. The steel rail sleepers are horizontally arranged and are perpendicular to the running direction of the maglev train. Every two F-type steel rails are arranged at the two ends of the top of the corresponding steel rail sleeper. Every two supporting columns are arranged at the two ends of the bottom of the corresponding steel rail sleeper and provided with rail bearing tables connected with the bottom of the corresponding steel rail sleeper through fastener units. The height H of each supporting column is larger than or equal to 1.1 m and smaller than or equal to 1.3 m and the interval between every two adjacent supporting columns is larger than or equal to 0.5 m and smaller than or equal to 1.4 m. By the adoption of the discrete type column type rail bridge system, an overhaul person can penetrate the rail bridge system conveniently, and the problem that an existing rail is not suitable for the intra-garage overhaul of the maglev train is solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Pesticide spraying device for greenhouse

InactiveCN111296397AReduce volumeEasy to walk throughInsect catchers and killersAgricultural scienceGreenhouse

A pesticide spraying device for a greenhouse comprises a fixed plate and a movable limiting plate, a mixed pressure box is fixedly arranged on the end face of the top of the fixed plate, a supply device is arranged in the mixed pressure box, a moving device is arranged in the movable limiting plate, and a spraying device body is arranged on the lower side of the moving device. The supply device comprises an air compressor fixedly arranged on the top end face of the mixed pressure box, and a mixed pressure cavity is formed in the mixed pressure box. The size of the pesticide spraying device issmall, so that the pesticide spraying device can conveniently pass through plants, damage to the plants is reduced, the device is further provided with a selection mechanism, the spraying height and the spraying strength can be selected according to needs, and the device is further provided with a quantifying mechanism, so that quantitative and accurate mixing is achieved, meanwhile, contact between workers and pesticide is reduced. And meanwhile, manual participation can be avoided when the device is used.

Owner:WENZHOU CHENRAO MASCH TECH CO LTD

A city road separated by people and vehicles

InactiveCN103485251BSolve the phenomenon of mixed use of people and vehiclesImprove securityRoadwaysClimate change adaptationEngineeringGreen belt

The patent of the invention discloses an urban road separating pedestrians from vehicles. All the components of the cross section of the urban road are not arranged on one horizontal plane, and are designed into concave or convex trapezoidal cross sections; green belts are designed into inclined planes meeting the head room of sidewalks to separating vehicles from pedestrians, so that motor vehicles driven on the bottom surfaces or (the top surfaces) and pedestrians walking on the top surfaces or (the bottom surfaces) have different ways and are not mutually interfered; pedestrian posterns or pedestrian footbridges are arranged at intersections, and pedestrian zebra crossings and pedestrian traffic lights are needless. The urban road separating pedestrians from vehicles avoids the phenomenon that the pedestrians and the vehicles are crowded in the same road, avoids traffic accidents of the pedestrians and the vehicles, provides convenience for the old, children, the disabled and other people in crossing the road, reduces damage to human beings caused by traffic pollution such as exhaust gas, noises, vibration and dust, and facilitates laying, repairing and maintaining various urban pipelines.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com