Energy-saving and emission-reduction tunnel kiln suitable for firing of ceramic products

A technology of energy saving and emission reduction and tunnel kiln, which is applied in the production of ceramic materials, furnace types, furnaces, etc., can solve the problems of unsatisfactory reflow application of waste heat reuse, uneven cross-section temperature, low energy utilization rate, etc., and achieve improvement The effect of energy saving and emission reduction, temperature stability and uniformity, and the effect of improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

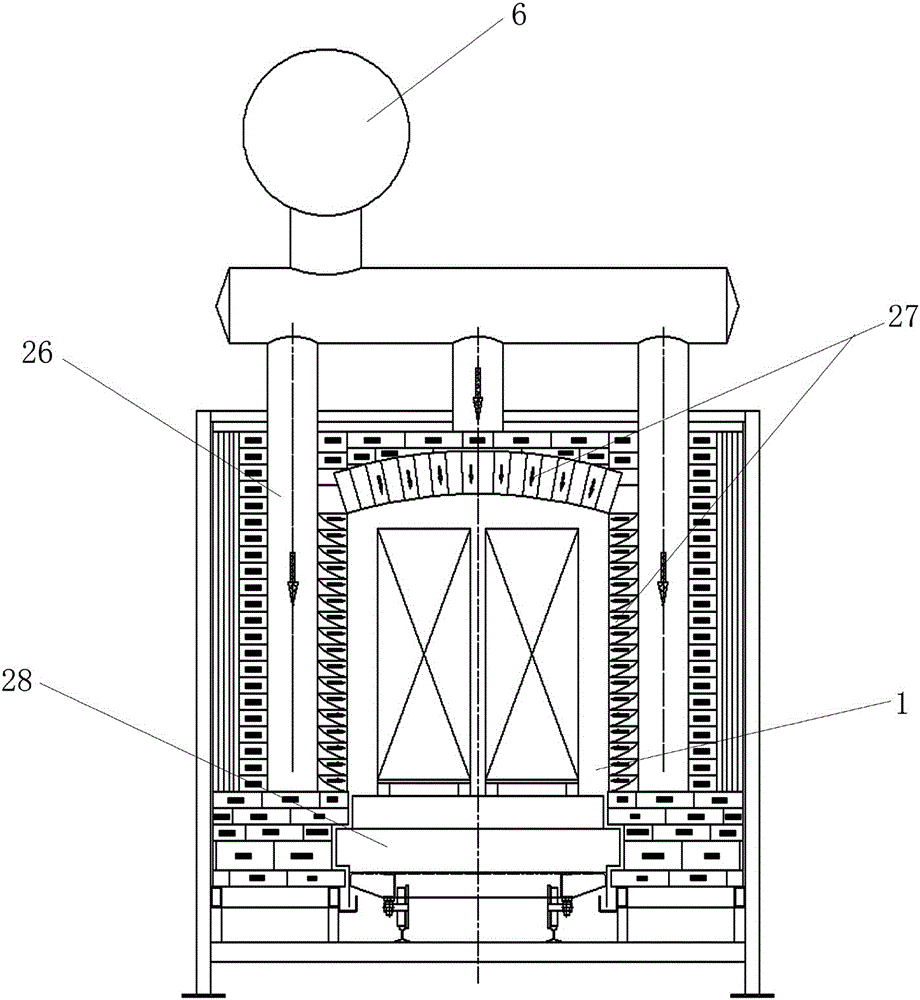

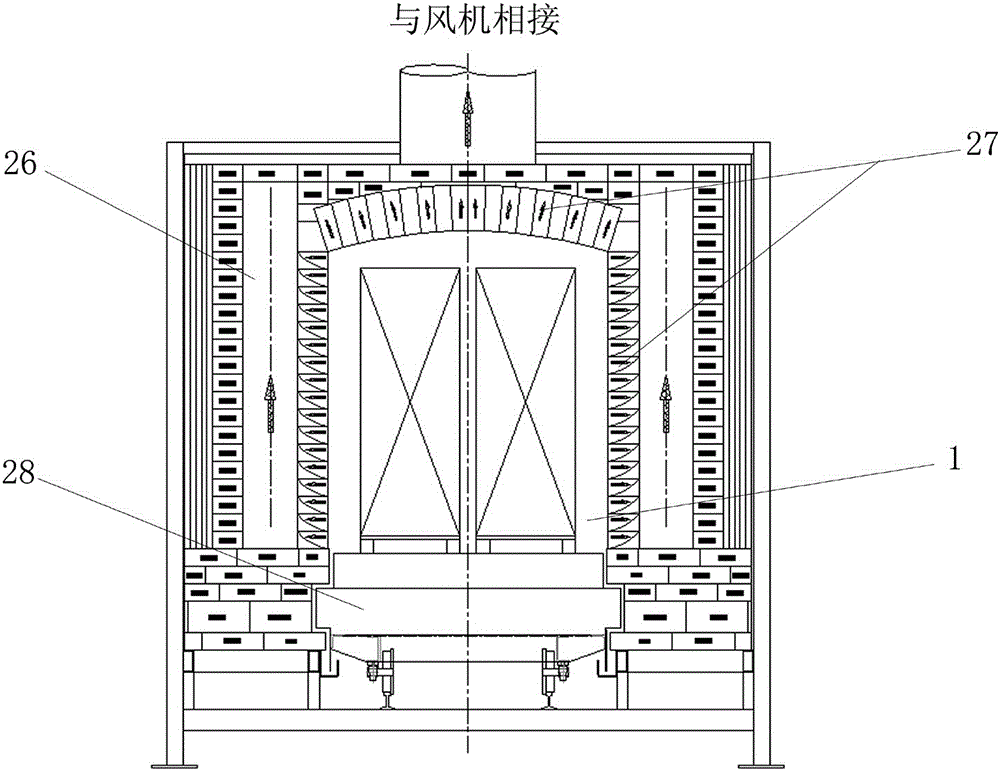

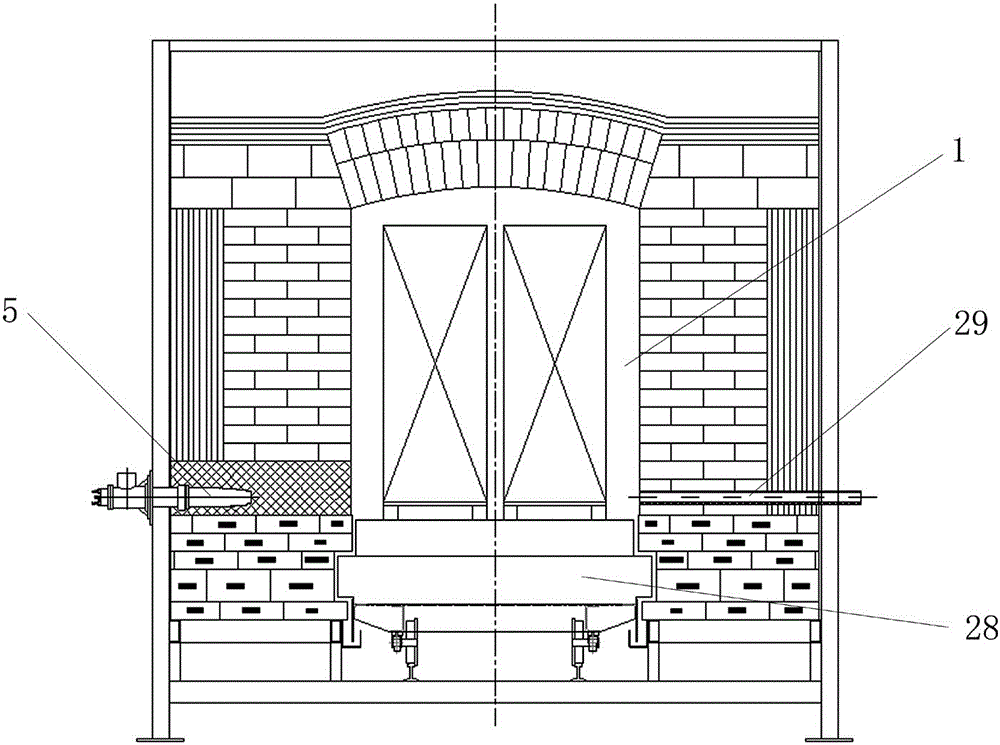

[0036] As shown in the figure, an energy-saving and emission-reducing tunnel kiln suitable for firing ceramic products includes a kiln body channel, a fan system, and a combustion system. A kiln car 28 is installed or loaded with ceramic embryo products and moved in the kiln body channel 1 . The kiln channel 1 has a total length of 82 meters and is divided into six sections, which are respectively an oxidation evaporation section 20, a strong oxidation section 21, a strong reduction section 22, a firing section 23, a heat preservation section 24, and a cooling section 25, wherein the oxidation evaporation section Area 20 is the drying zone 12, and the drying zone 12 is 0-15 meters of the kiln body channel, with a length of 15 meters. Air ducts are respectively provided at the 2nd, 4th and 10th meters of the entrance of the kiln body channel. 2 and the 10th meter are connected to the inlet smoke exhaust fan 2 through the air duct to exhaust outwards (such as image 3 As shown),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com