Pre-stress pipeline dredging device as well as a manufacturing and application method thereof

A technology of prestressed pipes and steel pipes, applied in the field of dredging devices for prestressed pipes during bridge construction, can solve problems affecting the penetration of prestressed steel bars, breakage of prestressed pipes, prolonging construction hours, etc., and achieve rapid dredging and cost saving , Wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solution of the present invention more clearly understood, it will be described in detail below in conjunction with the accompanying drawings and embodiments.

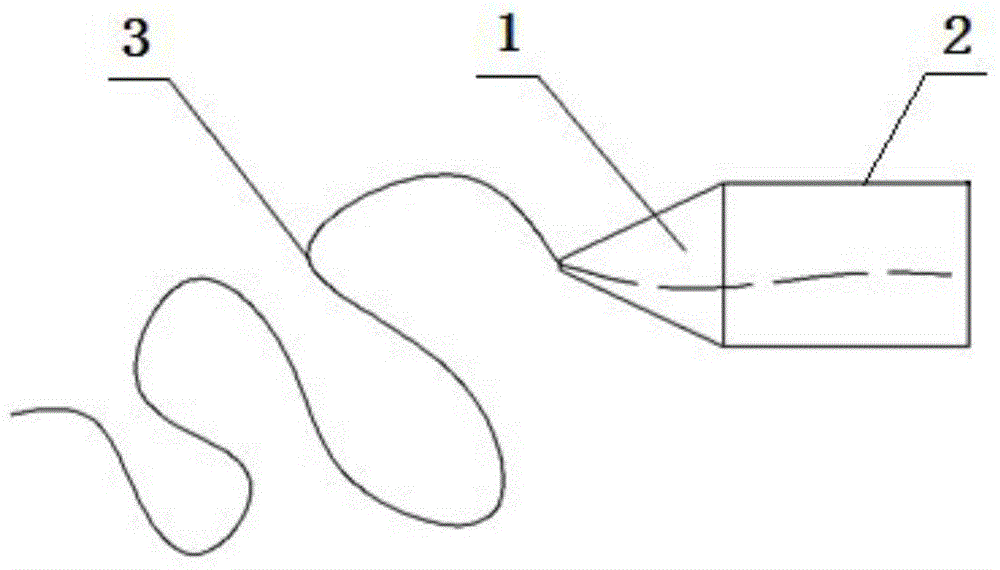

[0024] Referring to the accompanying drawings, the prestressed pipeline dredging device of the present invention includes a cone 1 and a steel pipe 2, the diameter of the bottom of the cone 1 is the same as the diameter of the steel pipe 2 and the two are connected as one by welding, the cone The top of the body 1 is provided with a small hole for passing through the steel strand 3, and the steel strand 3 is fixed to the cone 1 through the small hole.

[0025] Prestressed pipeline dredging device of the present invention, the building size of its each part is:

[0026] The overall length after the connection of the cone 1 and the steel pipe 2 is 12-13cm;

[0027] The diameter of the steel pipe 2 is 8-9 cm smaller than that of the prestressed pipe.

[0028] The making and using me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com