Distribution transformer temperature rise test winding temperature on-line test system and method

A technology for distribution transformers and temperature rise testing, which is used in transformer testing, thermometers, and thermometers using electrical/magnetic components that are directly sensitive to heat. problem, to achieve the effect of simple operation, solving the problem of test accuracy, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

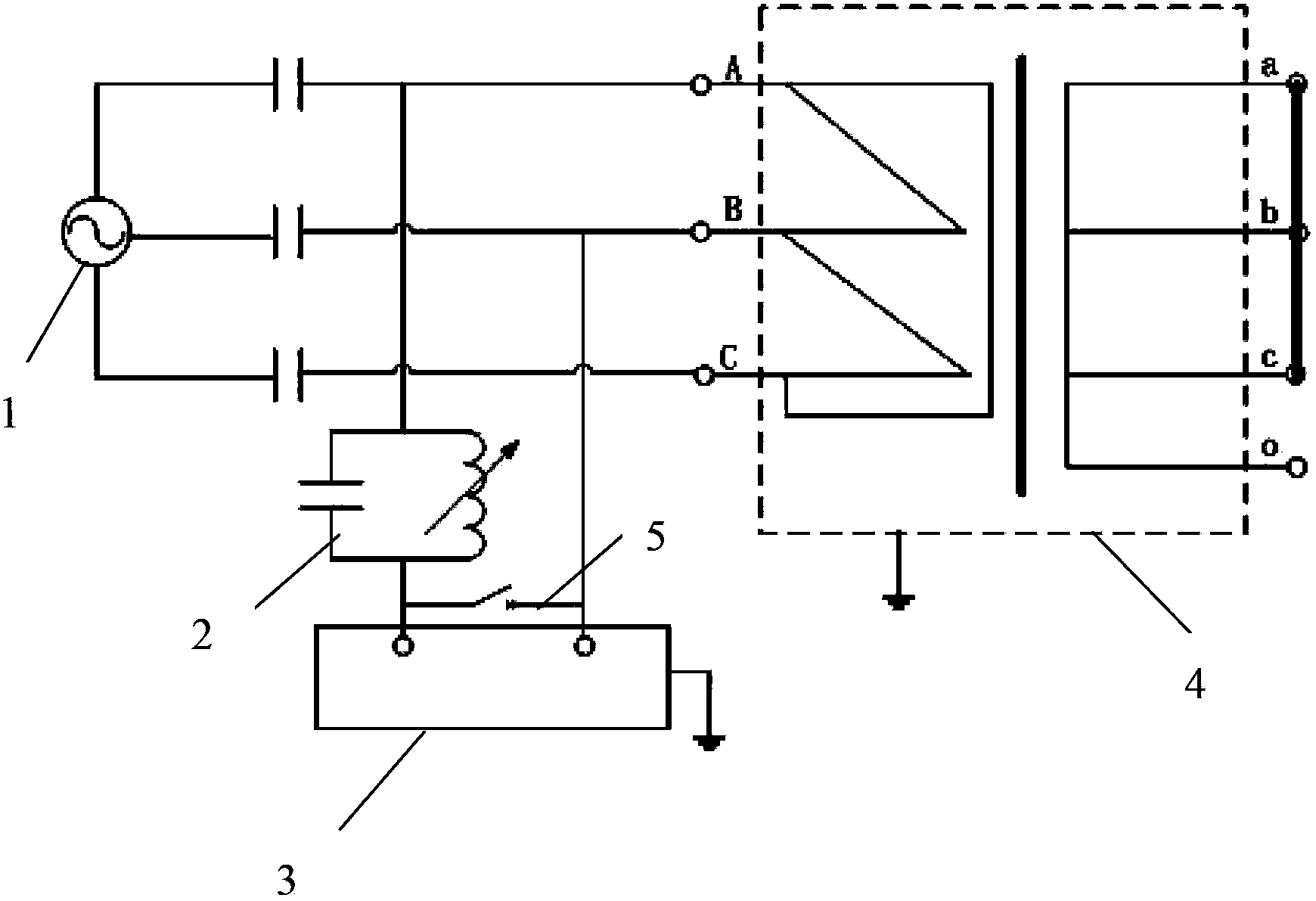

[0020] Such as figure 1 Shown is the distribution transformer temperature rise test winding temperature online testing system of the present invention, wherein, 1 is a three-phase power supply, 2 is a parallel resonant circuit, 3 is a DC resistance tester, 4 is a distribution transformer, and 5 is a switch.

[0021] Each phase of the three-phase power supply 1 is connected in series with a capacitor and then connected to the distribution transformer 4, the DC resistance tester 3 is connected in parallel with the pressurized winding line to be tested, the parallel resonant circuit 2 is electrically connected with the DC resistance tester 3, and the switch 5 is connected Between the input terminal and the output terminal of the DC resistance tester 3, the DC resistance tester 3 is short-circuited when the switch 5 is closed, and the DC resistance tester 3 works...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com