Mems device mechanism enhancement for robust operation through severe shock and acceleration

A system device, a technology formed by the structure, applied in the direction of measuring device, measuring acceleration, speed/acceleration/impact measurement, etc., can solve problems such as sensor failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

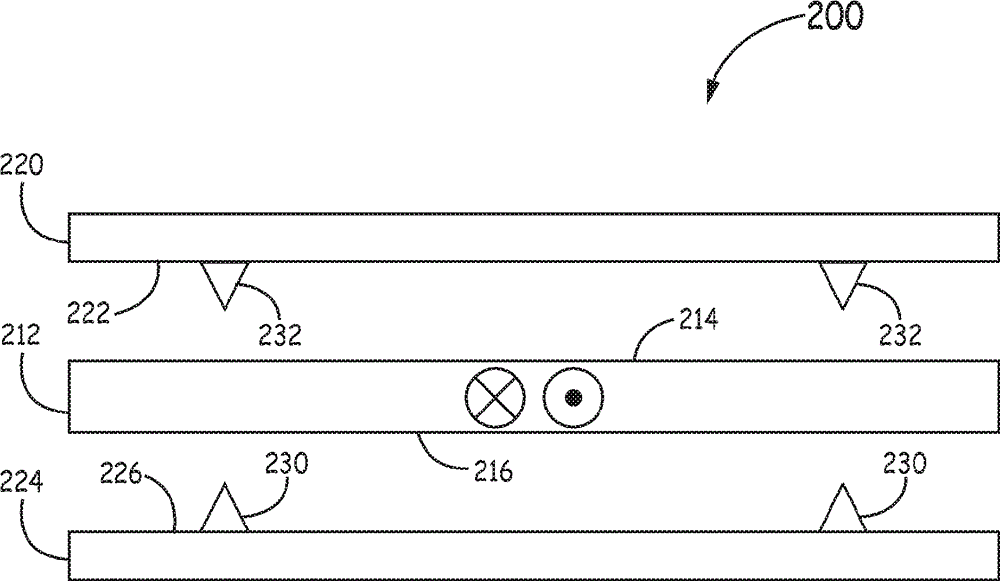

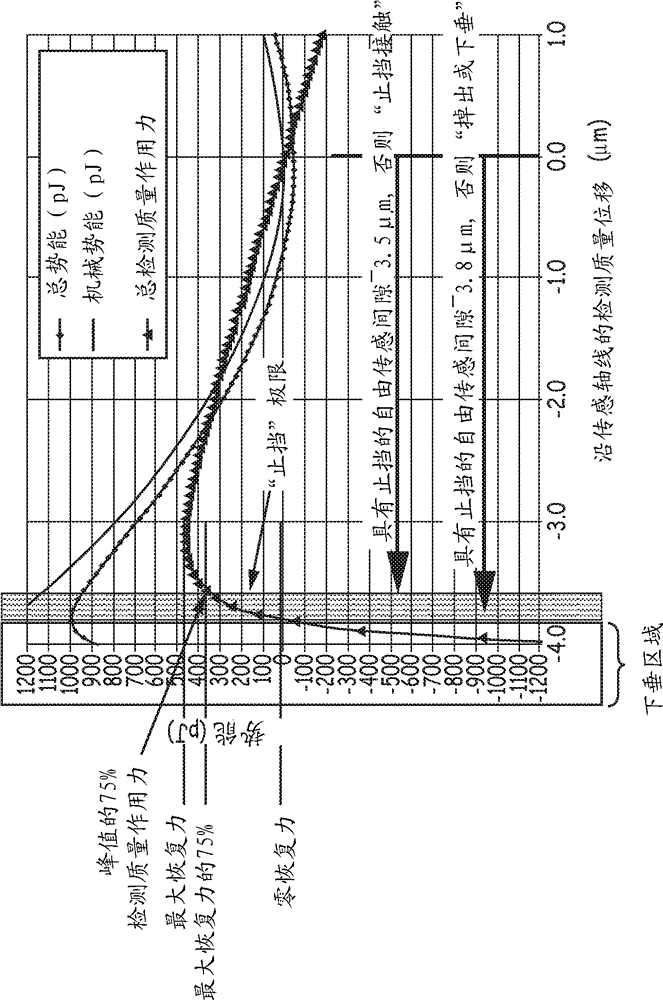

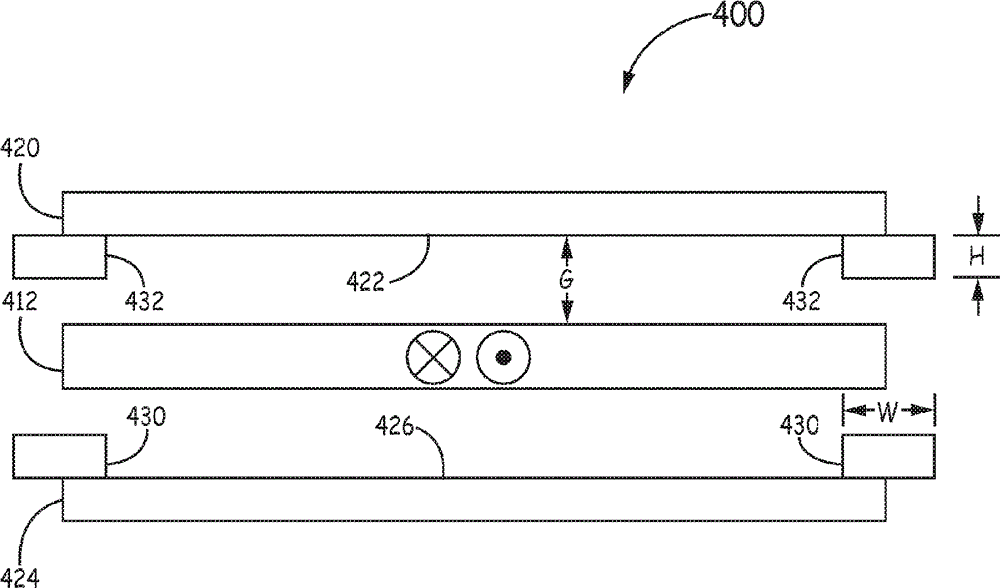

example 1

[0058] Example 1 includes a MEMS device comprising: at least one proof mass having a first surface and an opposing second surface, the proof mass configured to have a first voltage and motor movement in a first horizontal direction; a sensing plate separated from the proof mass by a first sensing gap, the first sensing plate having an inner surface facing the first surface of the proof mass and having a voltage different from the first voltage a second voltage; and a first set of stop structures on the inner surface of the first sense plate and electrically isolated from the first sense plate, the first set of stop structures configured to prevent The inner surface of the first sensing plate is in vertical contact with the proof mass, and the first set of stop structures has substantially the same voltage as that of the proof mass; wherein the first set The stop structure is dimensioned to minimize energy exchange when in contact with the proof mass during an impact or acceler...

example 2

[0059] Example 2 includes the MEMS device of Example 1, further comprising: a second sense plate separated from the proof mass by a second sense gap, the second sense plate having the opposing an inner surface of the second surface and having a third voltage different from the first and second voltages; and a second set of stop structures located on the inner surface of the second sensor plate and electrically isolated For the second sensing plate, the second set of stop structures is configured to prevent the inner surface of the second sensing plate from contacting the proof mass in the vertical direction, and the second set of stop structures having substantially the same voltage as the proof mass; wherein the second set of stop structures are sized to minimize energy exchange when in contact with the proof mass during an impact or acceleration event.

example 3

[0060] Example 3 includes the MEMS device of Example 2, wherein the first and second sets of stop structures are each substantially the same size and shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com