Large field of view fast two-dimensional scanning mirror installation structure

A two-dimensional scanning mirror and installation structure technology, applied in the field of terahertz detection and imaging, can solve the problems of long imaging time, difficult high-speed scanning, difficult imaging detection of moving targets, etc., and achieve the effect of reducing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

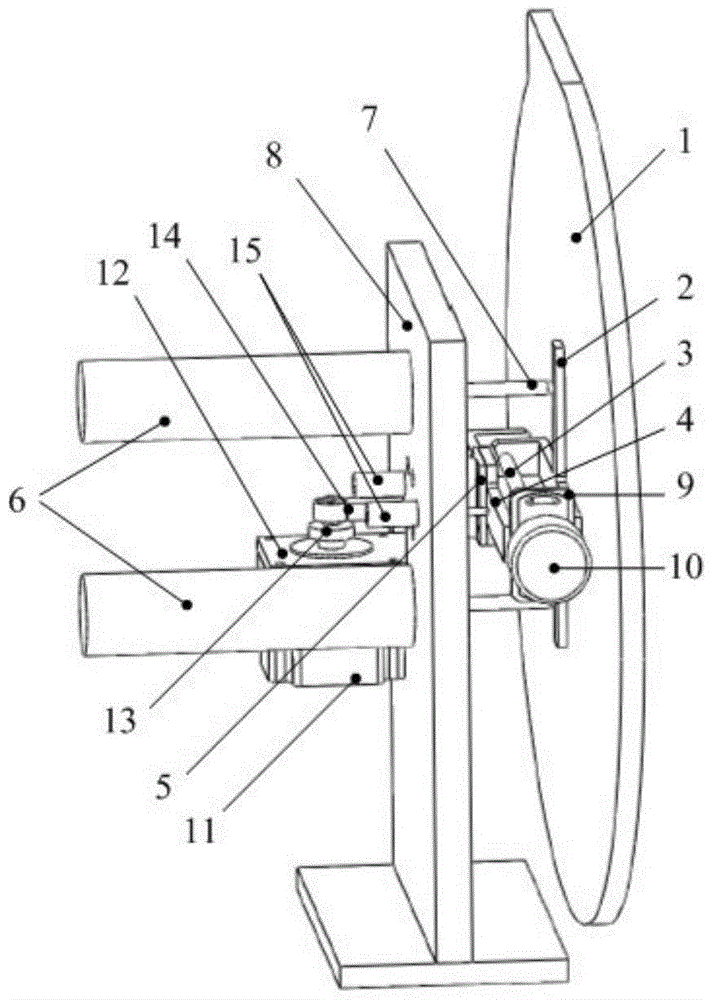

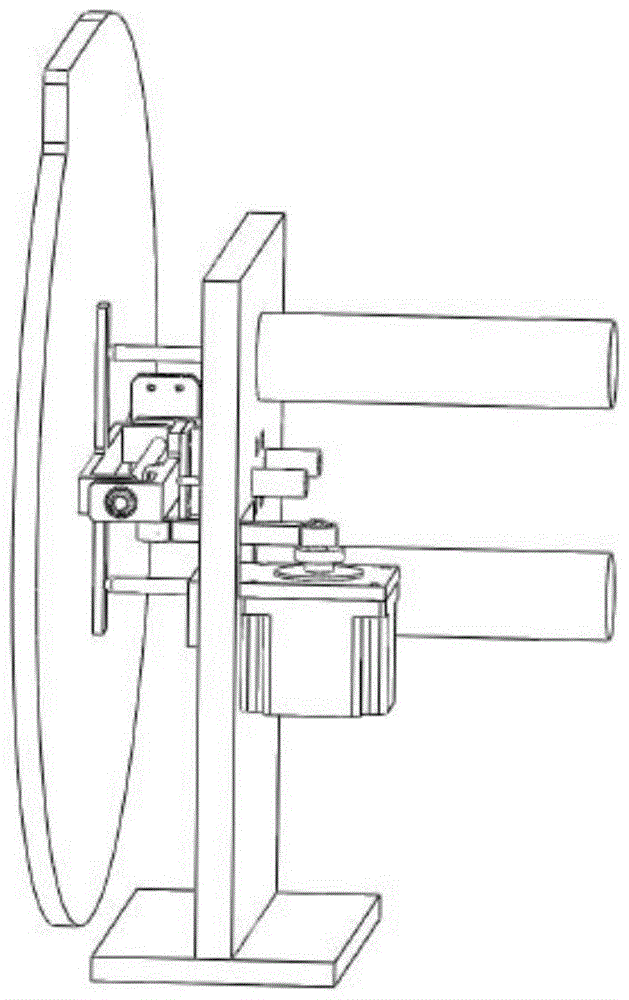

[0020] Attached below figure 1 with figure 2 The specific implementation of an embodiment of the large field of view fast scanning mirror of the present invention is described in detail:

[0021] Such as figure 1 with figure 2 As shown, the scanning mirror 1 is connected by the scanning mirror support frame 2 bonded on its back plate through the rotation joint formed between the pitch axis 3 and the pitch axis support frame 4, and the scanning mirror support frame 2 and the pitch axis 3 are connected by a tight The fixed screw is fixedly connected; the pitch axis support frame 4 is fixed on the bracket 8 through a one-dimensional flexible hinge 5, and the two voice coil motors 6 distributed up and down are pushed by linear motions with the same speed and opposite directions through the spherical actuator 7 installed on the shaft end The scanning mirror 1 swings around the pitch axis 3; the azimuth drive motor 11 fixed on the bracket 8 through the azimuth drive motor mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com