Ink spraying type liquid crystal coating machine and exhaust method for nozzle of coating machine

An inkjet and coating machine technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of lower production line production efficiency, increased nozzle exhaust time, liquid crystal waste, etc., to improve production efficiency and increase emissions speed, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

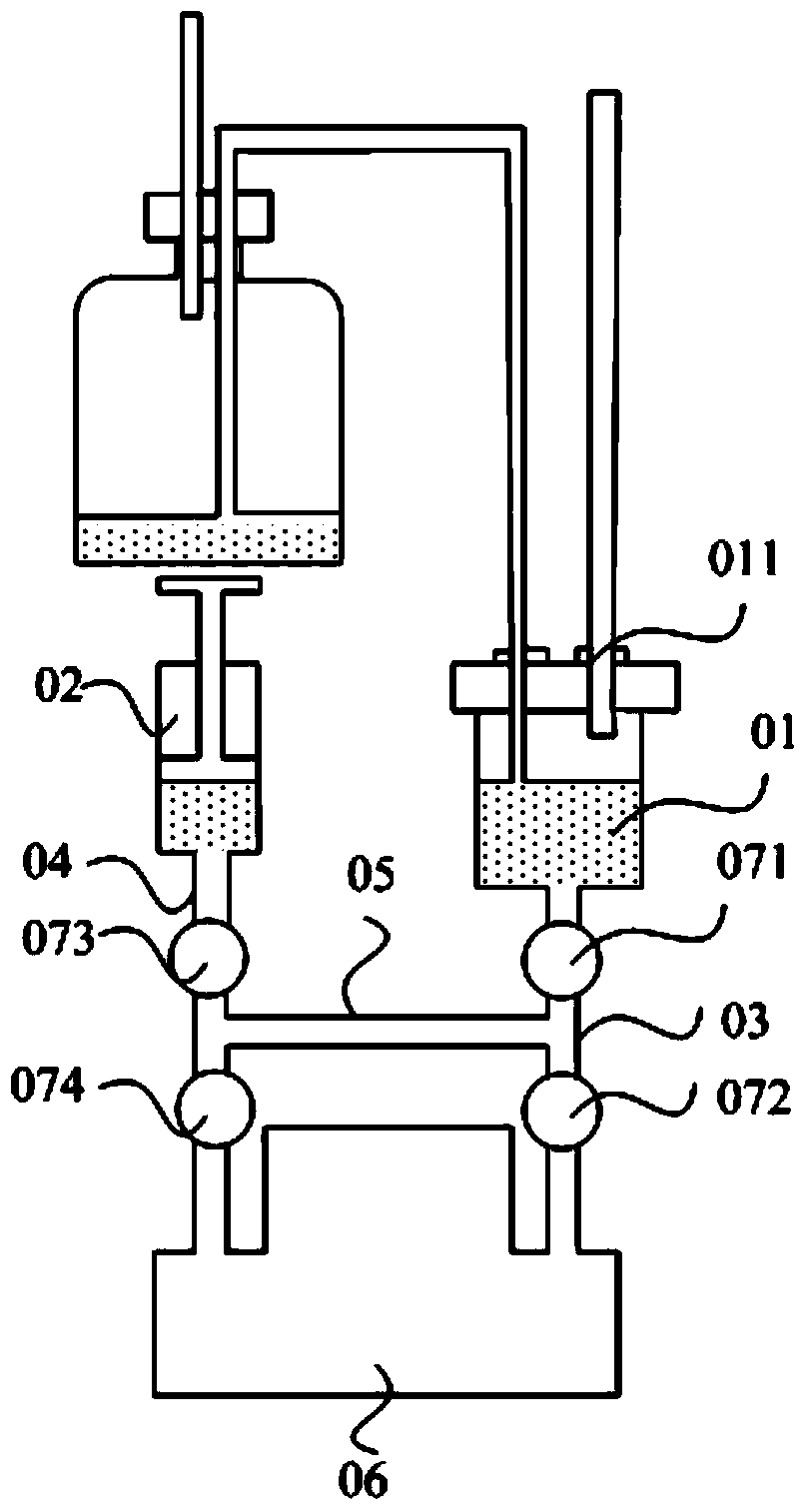

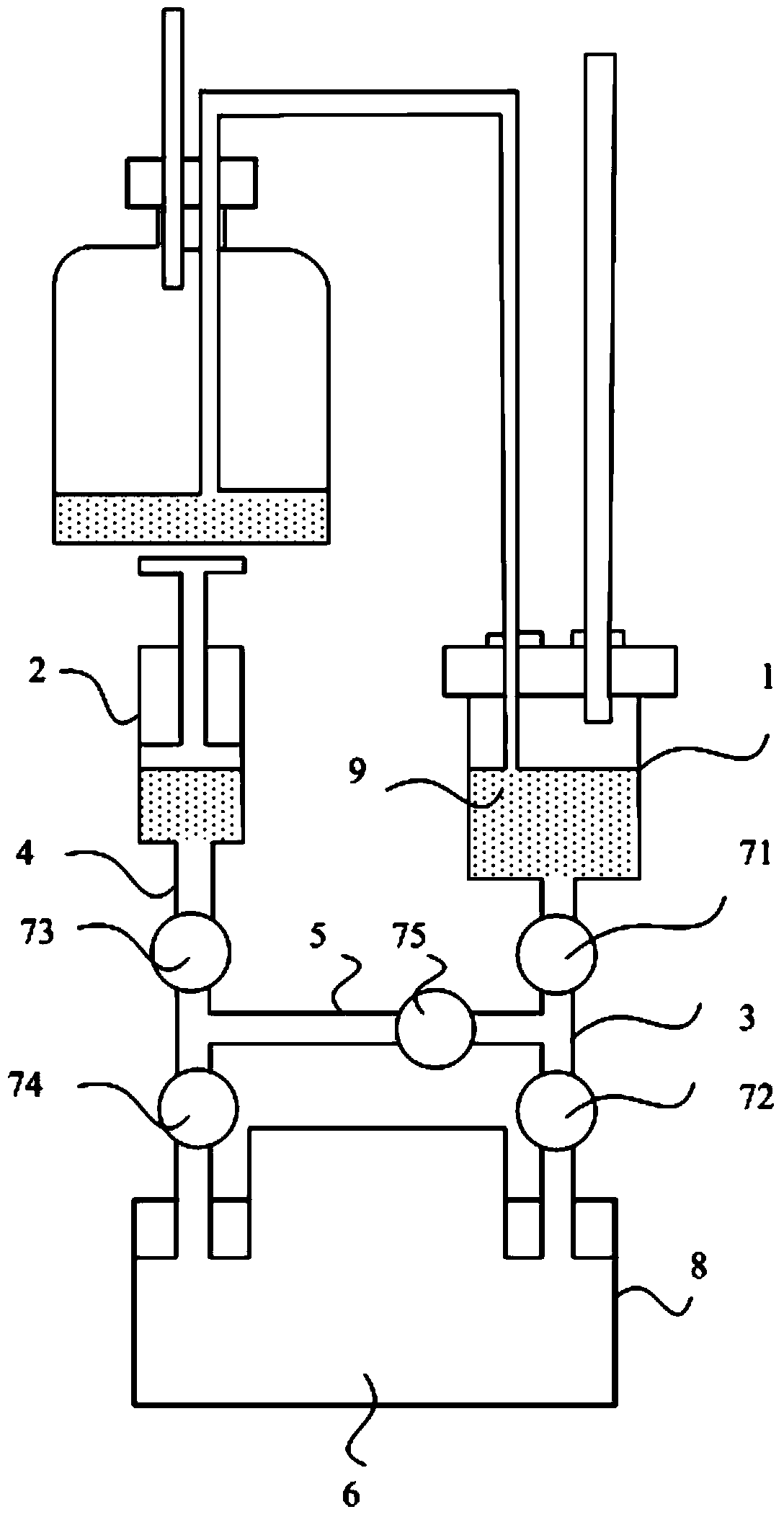

[0048] Such as figure 2 as shown, figure 2 The schematic diagram of the structure of the liquid crystal inkjet coating machine provided by the embodiment of the present invention, the liquid crystal inkjet coating machine provided by the present invention includes: a liquid storage device 1, an injector 2 on one side of the liquid storage device 1, and a nozzle 6 , the first communication pipeline 3 for connecting the liquid crystal outlet of the liquid storage device 1 with one opening of the nozzle 6, the second communication pipeline 4 for connecting the liquid crystal outlet of the injector 2 with the other opening of the nozzle 6, The third communication pipeline 5 for connecting the first communication pipeline 3 with the second communication pipeline 4, the first control valve 71 and the second control valve 72 arranged on the first communication pipeline 3 are arranged on the second communication pipeline 5 The third control valve 73 and the fourth control valve 74 ...

Embodiment 2

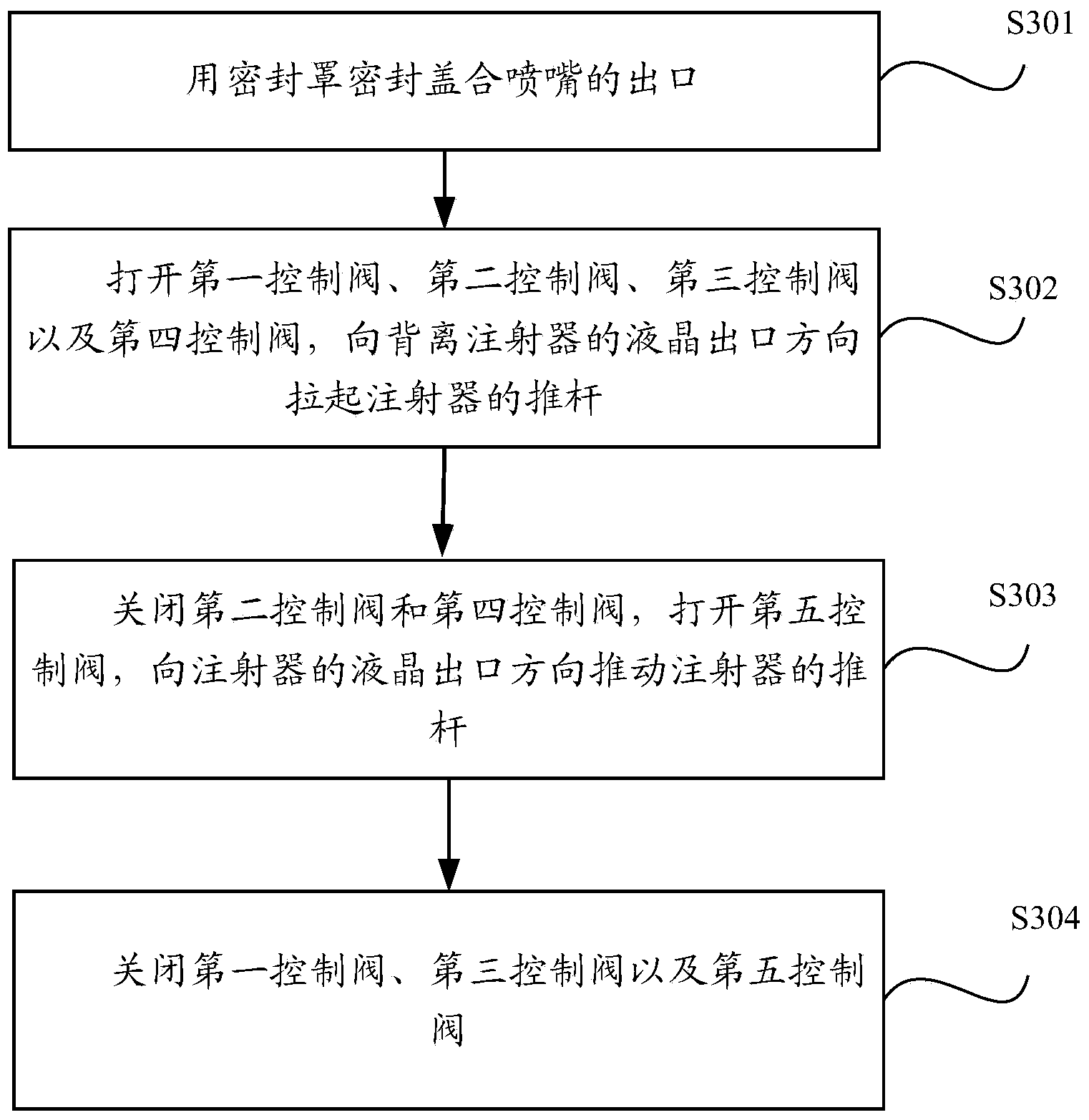

[0069] Such as image 3 as shown, image 3 The flow chart of the exhaust method of the nozzle of the liquid crystal inkjet coating machine provided by the embodiment of the present invention, the embodiment of the present invention provides an inkjet coating machine applied to any one of the above-mentioned embodiment one Exhaust methods for nozzles, including:

[0070] Step S301: sealing at least the outlet of the nozzle with a sealing cover;

[0071] Step S302: Open the first control valve, the second control valve, the third control valve and the fourth control valve, pull up the push rod of the syringe in the direction away from the liquid crystal outlet of the syringe, and the liquid crystal in the liquid storage device will pass through the first communication channel in turn. The pipeline, the nozzle and the second communication pipeline enter the syringe, and when the liquid crystal passes through the nozzle, the gas in the nozzle can be discharged into the syringe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com