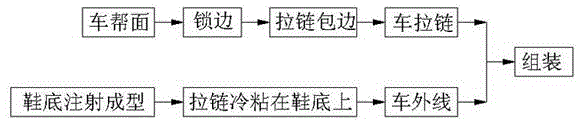

Combined type zipper shoes and production process thereof

A combination and zipper technology, which is applied to footwear, soles, insoles, etc., can solve the problems of difficult processing, high production cost, unfavorable promotion, etc., and achieve the effect of low cost, extended service life, and convenient opening of shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

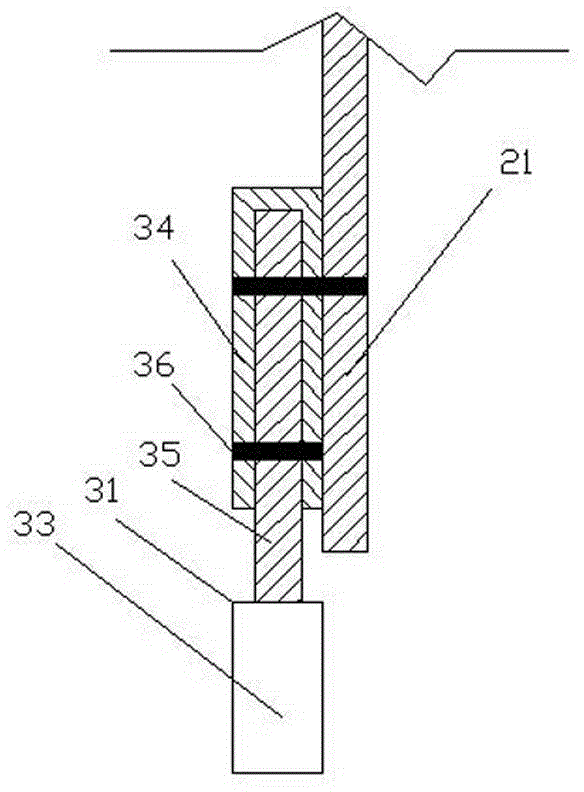

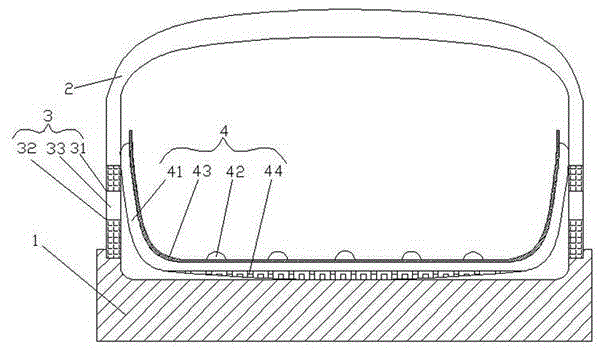

[0020] Such as Figure 1~4 As shown, a combined zipper shoe includes a sole 1, an upper 2, and a zipper 3 connecting the sole 1 and the upper 2 together, and an upper chain belt of a zipper 3 is provided around the bottom edge of the upper 2. 31, the top edge of the sole 1 is provided with a lower chain belt 32 of a zipper 3, the sole 1 is provided with an insole 4, and the insole 4 is surrounded by an upwardly folded dust-proof skirt 41. The dust-proof skirt 41 covers the inner side of the joints of the chain teeth 33 of the upper chain belt 31 and the lower chain belt 32 . The zipper 3 can well combine the upper 2 of the zipper shoe with the sole 1, and at the same time, the dustproof skirt 41 on the insole 4 cooperates with the zipper 3, which can effectively block the gap at the joint of the zipper 3 chain teeth 33. Dust, grit, stains, water spots, etc.

[0021] In this embodiment, the dust-proof skirt 41 is integrally made with the insole 4, and there is no need to sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com