A vibrating packing scraper device

A vibrating and scraping technology, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of easy deformation, affecting fabric coating, uneven coating, etc., to prevent defects and jumping, enhance filling and leveling effect, Reduce the effect of uneven filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

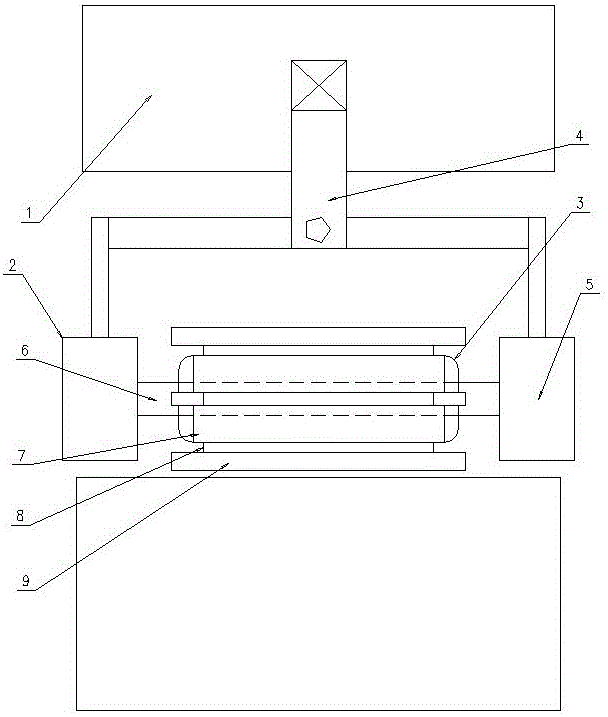

[0014] As shown in the figure, a vibrating filler scraper device includes: a frame 1, characterized in that: the frame 1 is provided with a vibration mechanism 2, a conveying scraper assembly 3, and the vibration mechanism 2 is located in the conveying Between the scraper assembly 3 and the frame 1, the vibration mechanism 2 is fixed on the frame 1 through the connecting plate 4, and the position of the vibration mechanism 2 corresponds to the conveying scraper assembly 3.

[0015] Preferably, the vibrating mechanism 2 is composed of a vibrating cylinder 5 and a protruding rod 6, the protruding rod 6 is connected to the vibrating cylinder 5, and the protruding rod 6 penetrates and sleeves the conveying scraper. Component 3.

[0016] Preferably, the conveying scraper assembly 3 consists of a conveyor 7, a conveying clamp strip 8 and a scraper 9. A number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com