Dry mix gypsum mortar production line

A gypsum mortar and production line technology, which is applied in the field of mortar manufacturing, can solve problems such as unstable project quality, poor quality, and long decoration time, and achieve the effects of convenient and fast packaging and transportation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

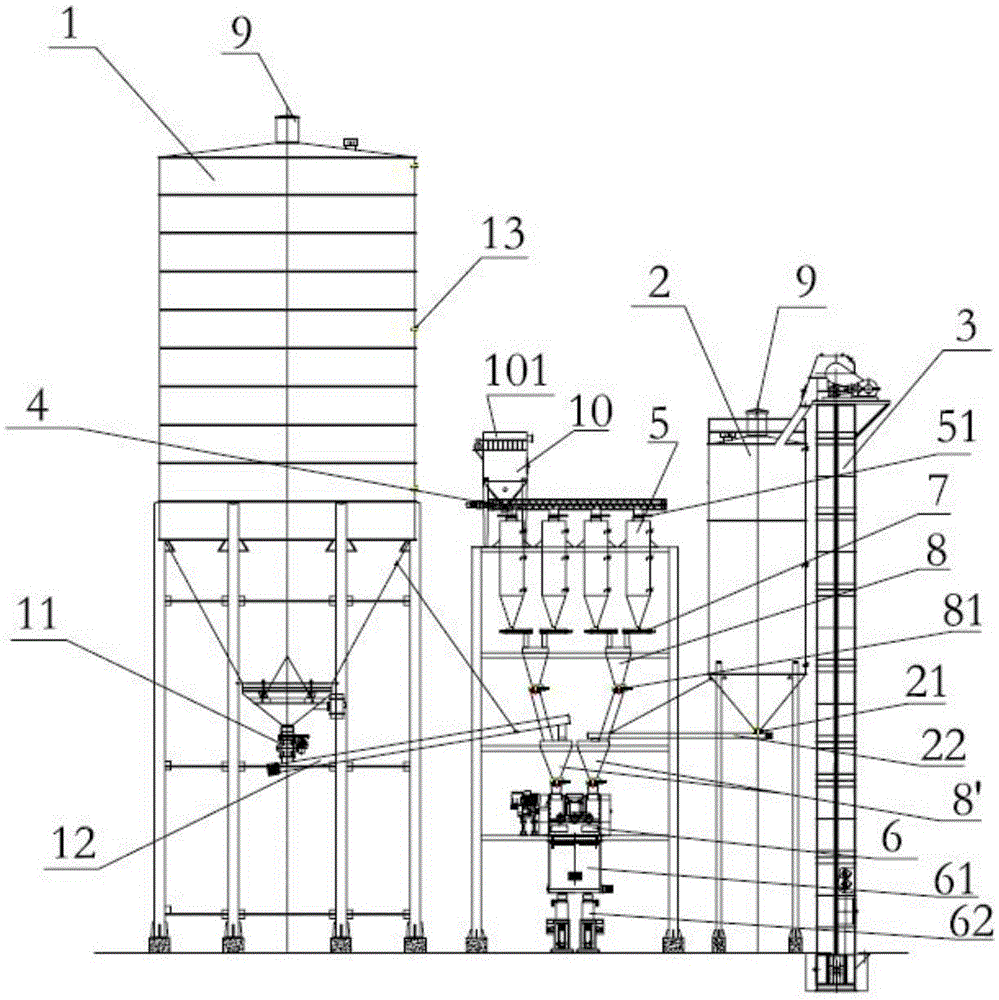

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] Such as figure 1 As shown, the present invention is composed of a first powder silo 1, a second portion silo 2 and an additive device, and a hoist 3 is arranged on one side of the second portion silo 2, and the upper end of the hoist 3 It is connected to the upper end of the second portion of the silo 2; the lower end of the first powder silo 1 is provided with a first discharge port 11, and a first screw conveyor 12 is provided below the first discharge port 11, A second discharge port 21 is provided at the lower end of the second powder hopper 2, a second screw conveyor 22 is provided below the second discharge port 21, and the additive device is located in the first powder hopper. 1 and the second batch silo 2, a plurality of second weighing devices 8' are connected below the additive device, and the output ends of the first screw conveyor 12 and the second screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com