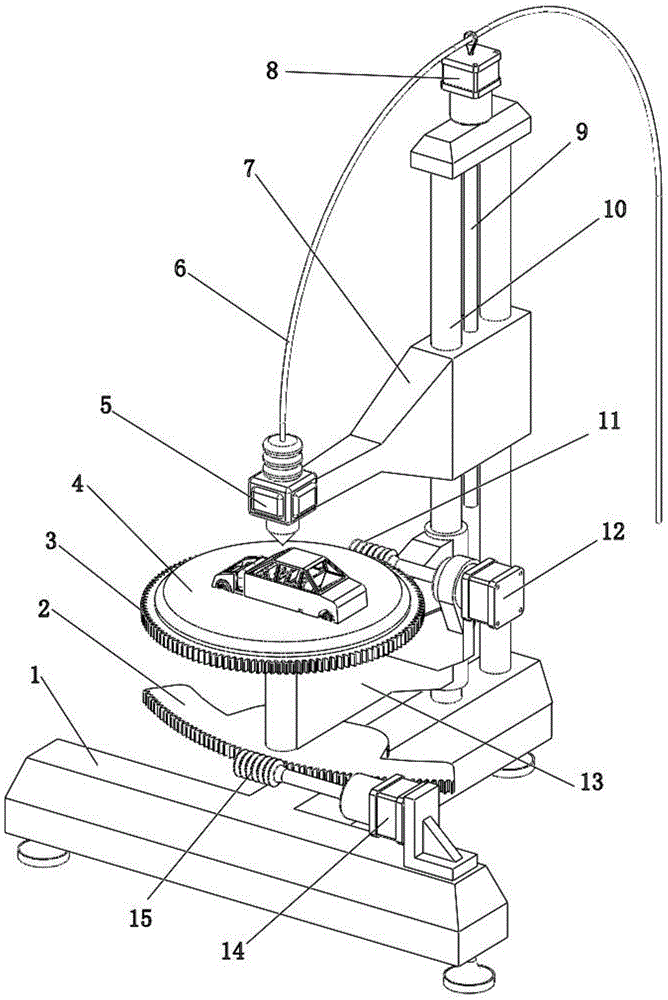

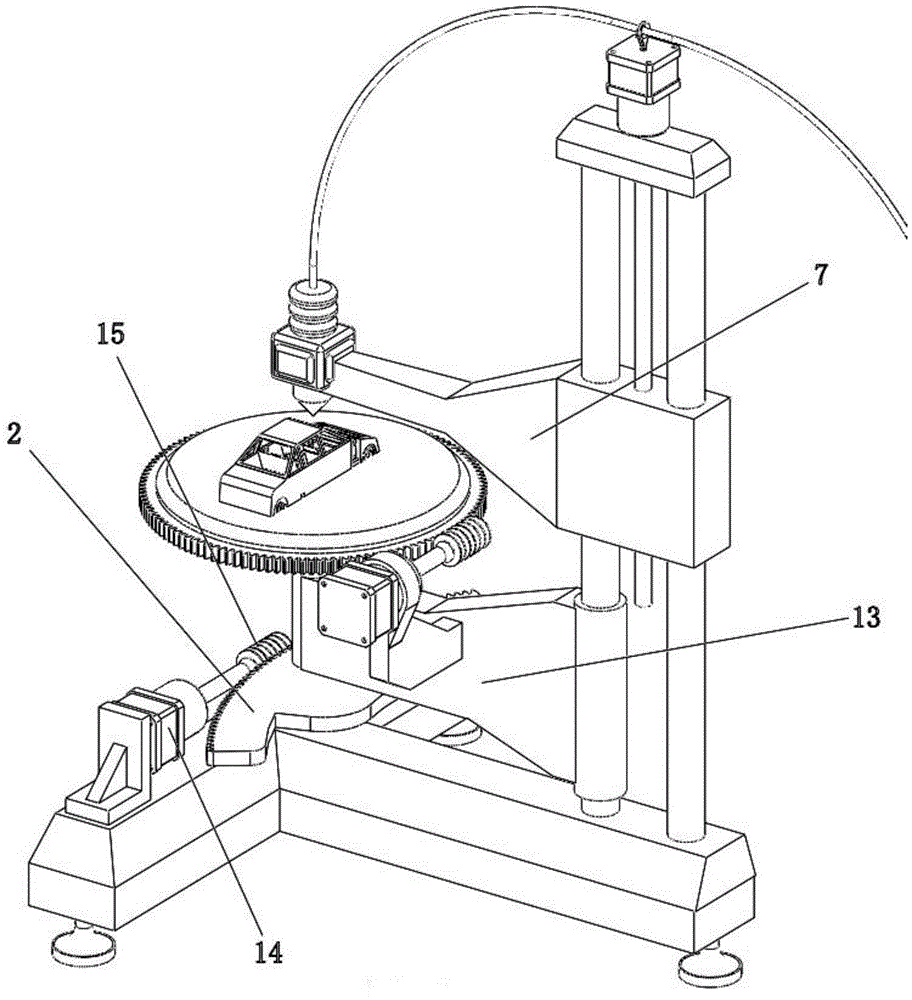

Numerical control positioning system of 3D printing machine

A positioning system and printer technology, applied in the field of 3D printer numerical control positioning system, can solve problems such as increasing the weight of the whole machine, and achieve the effects of simplifying the structure, high positioning accuracy, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In the three-axis (X-axis, Y-axis, Z-axis) numerical control positioning system of hot-melt deposition 3D printers in the prior art, almost all linear slide guides are used. Technically, the length of the linear guide rail is greater than the working stroke, and the guide rails must be perpendicular to each other. Therefore, the main structure of this type of 3D printer is mostly box-type, which is bulky and heavy. During the 3D printing process, the stepping motors driving the X-axis and the Y-axis are constantly cooperating under the control of the computer to form each curve or straight line in the model fault, that is, a slice. Therefore, their workload is high and wear and tear are also serious. The Z axis only moves when the layer height increases, and its maximum stroke is the height of the model. It prints a model and travels once, so the wear of the Z-axis is very small, and its impact on the accuracy and service life of the 3D printer is relatively much smal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap