Plane air refueling auxiliary device

A technology for aerial refueling and auxiliary devices, which is applied to aircraft parts, transportation and packaging, etc., can solve problems such as difficult operation, and achieve the effect of reducing the difficulty of flight requirements, adjusting the position of the aircraft, and reducing docking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

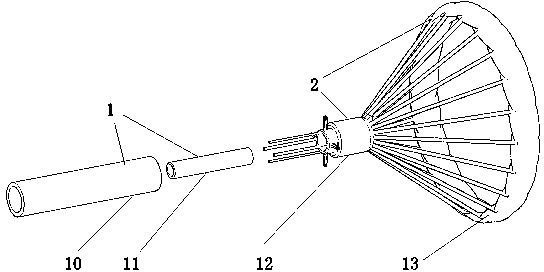

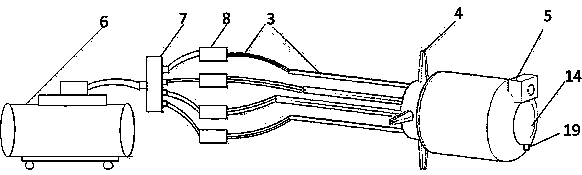

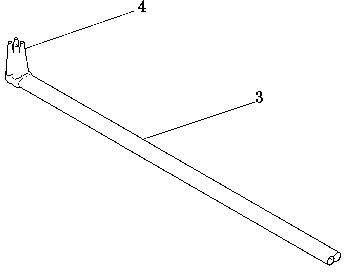

[0009] Embodiments are described in detail with reference to the accompanying drawings. An aircraft aerial refueling auxiliary device, including a double-layer oil delivery hose 1, a fuel delivery machine cone sleeve 2, an exhaust hose 3, an exhaust nozzle 4, a camera device 5, an air compressor 6, and an air distribution pipe joint 7 , a digital proportional valve 8, a control panel 9, an infrared distance sensor 19 and a circuit control module, wherein the double-layer oil delivery hose 1 is composed of an outer layer protective cover 10 and an inner layer oil delivery pipe 11, and the oil delivery machine taper sleeve 1 is composed of a taper handle 12 The umbrella cover 13 is fixedly formed, and the tapered handle 12 inside the umbrella cover 13 is provided with a camera device 5 and an infrared distance sensor 19. The middle part of the tapered handle 12 is provided with an axial oil delivery hole 14, and the outer protective cover 10 It is connected with the outer ring o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com