Comprehensive moving transportation platform capable of lifting

A technology of all-round movement, lifting and transportation, applied in the directions of lifting frame, transportation and packaging, lifting device, etc., can solve the problems of manual operation of the adjusting rod, laborious height adjustment, inability to move independently, etc., to achieve flexible mobility, labor saving, Good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

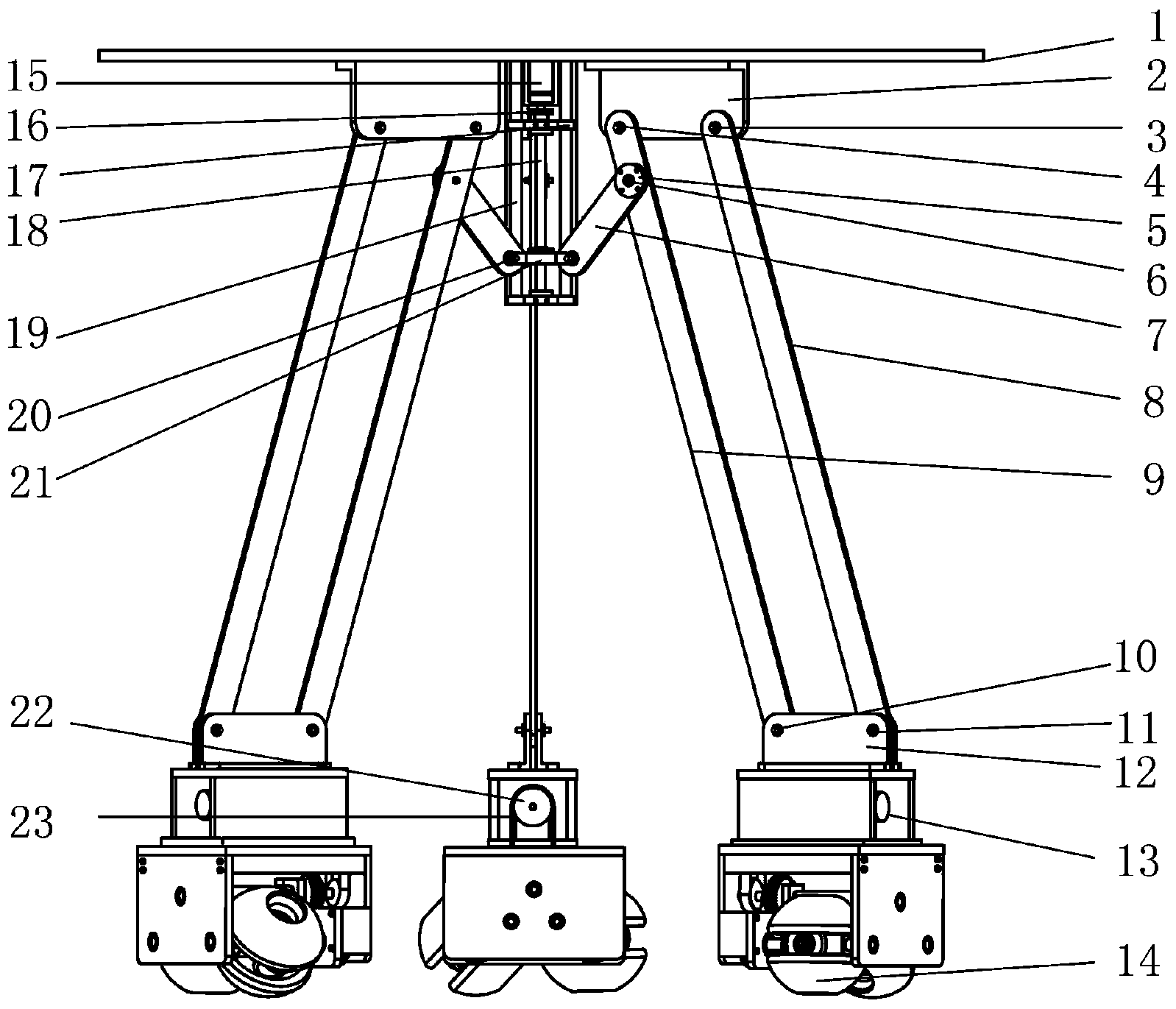

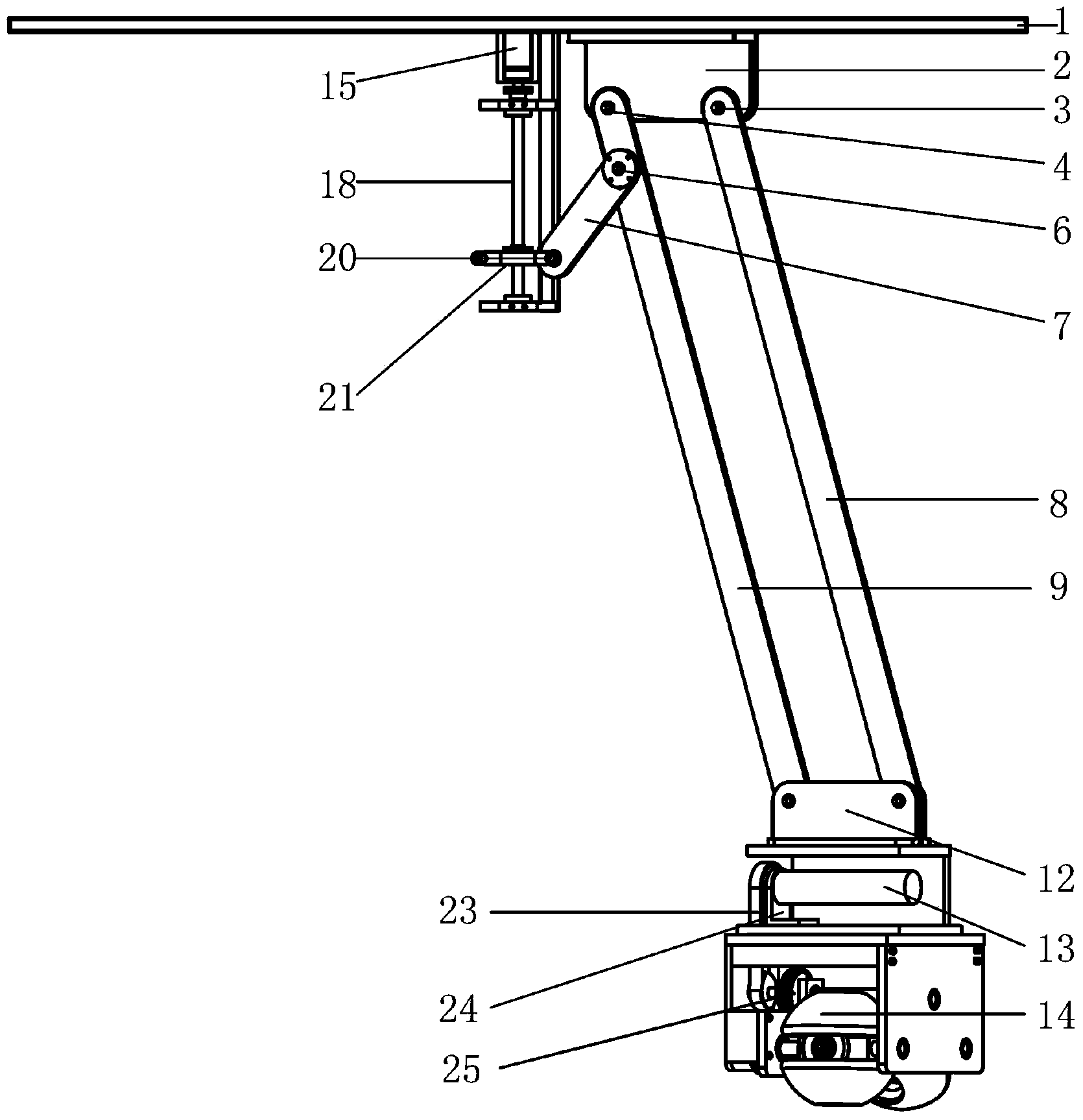

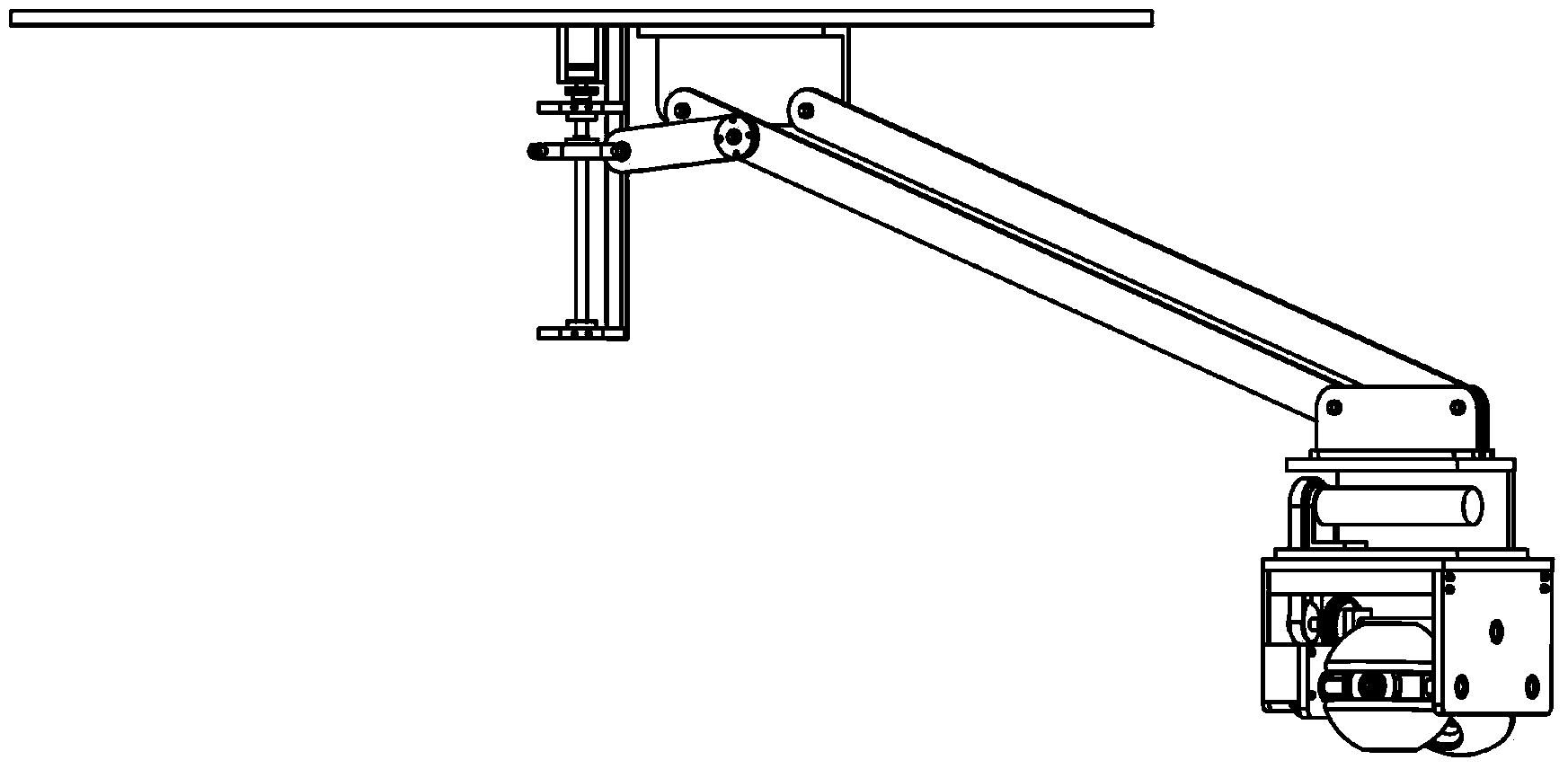

[0015] In order to further understand the omni-directional mobile liftable transportation platform, the description is as follows in conjunction with the accompanying drawings.

[0016] It includes: it includes a platform 1, a screw motor 15 and an upper fixing plate 2 are fixed on the platform 1, a bracket rod a and a bracket rod b are fixed on the upper fixing plate 2 by bolts, and the other ends of the bracket rod a and the bracket rod b are connected to the The lower fixed plate 12 of the support is connected, and the lower fixed plate 12 is connected with the omnidirectional wheel 20, and the upper fixed plate 2, the support bar a, the support bar b and the lower fixed plate 12 form a parallelogram support frame structure; The shaft device 16 is connected with the lead screw 18, the two ends of the lead screw 18 are restrained by the lead screw fixing plate 17, the lead screw fixing plate 17 is connected with the lead screw fixing side plate 19, the lead screw fixing side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com